But first let us explain what is a special tool called the Laser Seam Tracking Sensor that makes the job of the welder more efficient and accurate. It takes advantage of lasers to trace the metal's edge meticulously in an effort to ensure the weld is spot on. This tool has a very significant role because it can prevent mistakes during the welding process.

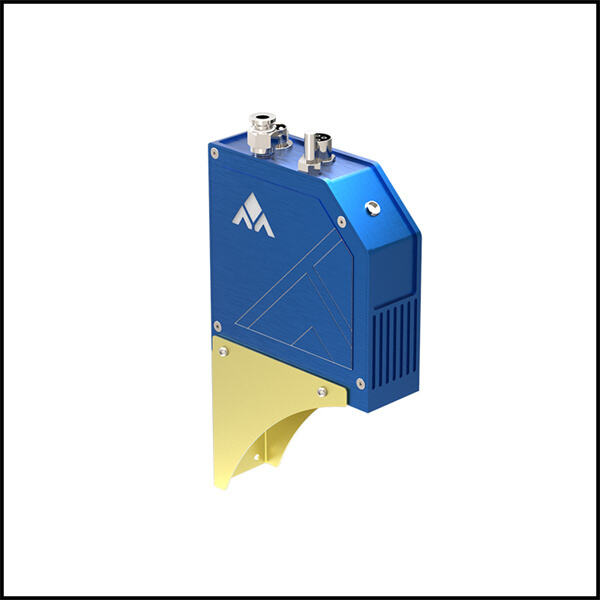

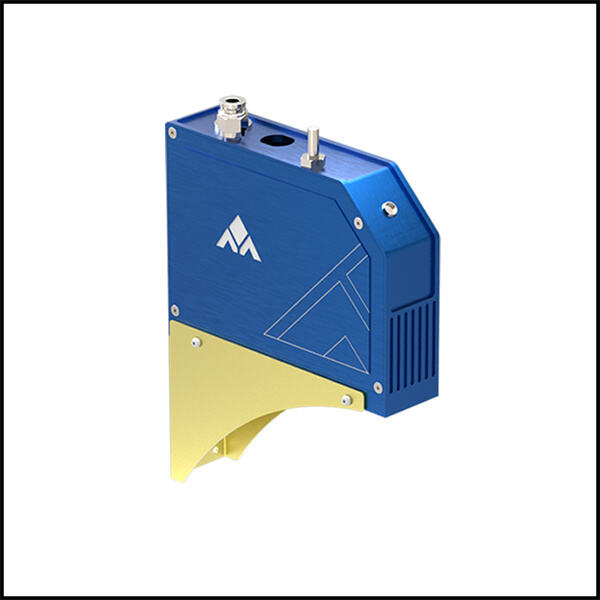

Of course, welding is hard work, but using our Laser Seam Tracking Sensors from MINYUE makes it so much easier. These laser beam sensor verify that the weld is applied correctly every time it happens. Welders with this technology to help them, spend less time correcting errors and more time making quality products, that work. This is significant because it keeps them from having to worry about that, and thus it enables them to pour all their energy into their craft and give a greater output.

Welding has a very high requirement for quality control. We want to ensure every weld we make is strong and going to last a long time. Minyue Laser seam tracking long range distance sensor ensures that every welding position is accurately located, ensuring that the welding quality meets high standards. This leads to fewer errors and overall better quality in our work. Strong reliable welds further develops confidence in our customers that we provide nothing but the best of products.

It takes a fair bit of time to make things, guards like welding. But we can save time with MINYUE's Laser Seam Tracking Sensors in manufacturing. This means every weld is perfect from the very first time, so we don’t go back later and have to fix errors. It makes the whole process more efficient. This high speed laser sensor has allowed us to manufacture faster and get into the homes of our audience sooner, fulfilling their wants and needs.

Welding requires a lot of precision. First, we need to get the weld to work and fit in the general structure of the rest of the machine. The Laser Seam Tracking Sensors can supercharge the accuracy of our welding jobs. So all of this technology is allowing welders to put their welds exactly where they need to be, so that our products will end up being stronger and last longer. When we weld better, it improves the performance and reliability of the parts that we produce.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.