Welders have a vital role in the modern economy. Welding is the process of melting two metal pieces together using heat. The intensity of this heat melts the metal and joins the two pieces as they cool down. But sometimes it can be a little difficult to make sure that the weld is in the correct place and it was executed right. This is where MINYUE laser seam tracking sensor step in to assist!

Automatic weld tracking sensors act like little buddies helping workers during welding process. They operate by tracking the weld seam path and monitoring its progress. This enables them to ensure that the welding is on the correct path and that the outcomes are quality. Utilizing these sensors, welders are more assured that their task will be a triumph.

Auto weld tracking sensors also enhance weld quality and accuracy, which is one of the key benefits of using them. This is because these MINYUE industrial laser sensor incorporate specialized technology that lets them detect any errors / deviations in the planned weld path. That means they can warn the welder right away if things aren’t going as they should.

Automatic tracking sensors monitor the weld seam continuously and make instant adjustments to maintain the weld in proper position. Doing so produces stronger, more reliable welds. In many sectors, achieving welds that fully comply with the very best quality standards is very crucial, and these sensors facilitate that.

Automatic tracking sensors also help workers perform faster and more productively alongside improved weld quality. As robots have taken over the chore of watching the weld seam, these sensors have allowed welders to do other necessary parts of their job. That means they have time to manage their time better and get more done.

Real-time monitoring of the welding process is only made possible by automatic weld tracking sensors, which is essential to provide accurate and consistent results. These MINYUE high speed laser sensor are sensitive enough to troubleshoot issues and fluctuations the moment they occur, enabling corrections to be made in real time when they are needed.

This kind of organized and readily available data makes it easier to inspect the weld and verify that it meets the required standards. Moreover, with these sensors being automated, a clear record of the welding process is created, making it easy to trace back any issues that might arise. MINYUE industrial laser distance sensor enables easier and more accurate record keeping, providing peace of mind to everyone involved.

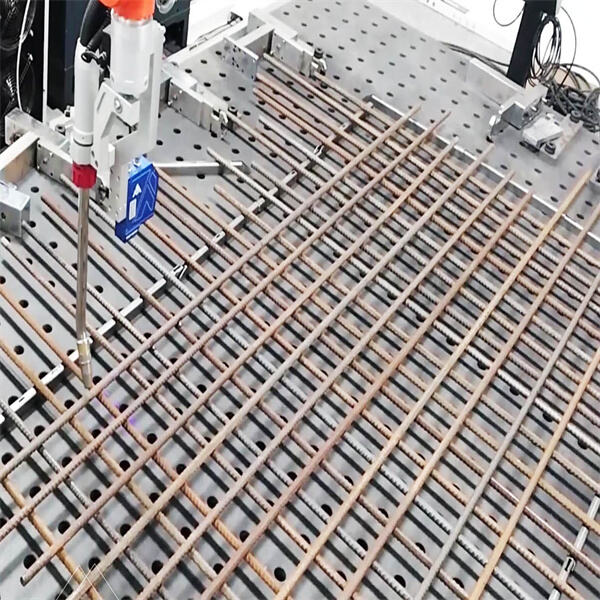

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

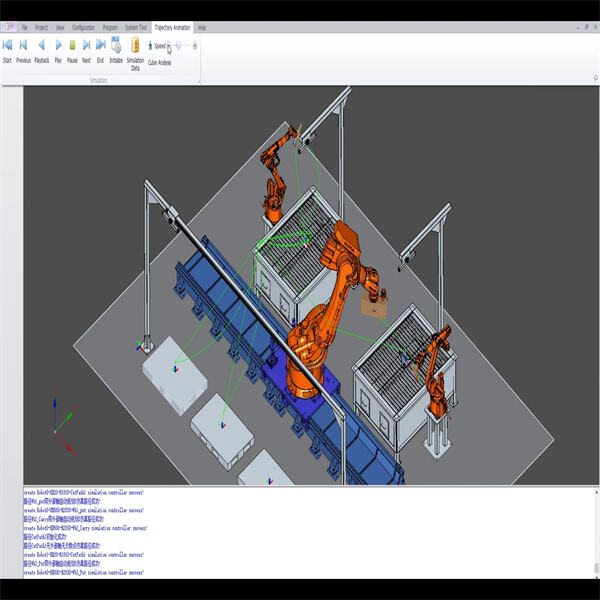

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.