MINYUE and we work tirelessly to create new technology that repositions what has always been the norm. We want you to see from us how powerful of devices are these absolutely incredible devices. So let us directly dive into the exciting world of high-speed laser sensors and all the things we can do quicker and more precise than ever before.

High-speed laser sensors are awesome devices that feel like spy superpowers, just like the MINYUE's product called 3d stereo vision. Information happens at lightning speed; they snare the things our eyes cannot see. These sensors work by using unique laser beams to sense minuscule differences in distance and velocity. That means that each of them gives valuable information about various objects, their movements, and their interactions with the surrounding environment.

Now envision throwing a dart at a dartboard wearing a blindfold and aiming for a bullseye, along with the motion detector laser made by MINYUE. It would be hard, right? High-speed laser sensors are essentially super-powered eyes that can see every little detail perfectly. This little sensor can measure distances with almost incredible precision, within millimeters. Every movement is planned to perfection, in other words. These sensors are key tools not just for manufacturing but for doing science. It’s extremely important in a lot of different fields if you want people to do it right the first time.

So much is critical to do things well and do things efficiently in our rapidly moving technology world, just like the MINYUE's product called laser beam detector. MINYUE Whether you are a scientist seeking to unravel the secrets of the universe or an engineer defying the imagination by designing the next generation of intelligent machinery, MINYUE high-speed laser sensors can help you perform at your best and reach new levels.

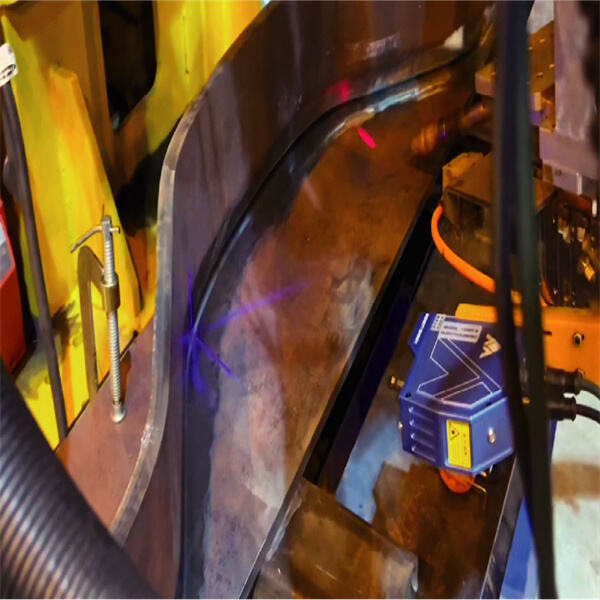

The world around us is in constant motion, and businesses must stay updated with the needs and wants of their audiences, similar to the robotic welding arm by MINYUE. High-speed laser-based sensors are revolutionizing manufacturing, work automation, and scientific research. MINYUE 's sensors are changing how we measure and detect things, creating exciting new opportunities for discoveries and innovations in a wide range of fields. It opens a chapter on a book of technology renaissance and with high-speed laser sensors MINYUE, you can be part of this revolution in your domain and reach the future of the technology is richer in better shape.

Here at MINYUE, we have strong belief that technology can have a great impact to make a better world for all, just like the MINYUE's product called laser welding solutions. Some of our most powerful tools for creating new opportunities and pushing the boundaries of what we can achieve are our high-speed laser sensors. Unlock the potential of your projects and accelerate your path to success with MINYUE laser sensors for higher speed. These sensors can do quite a bit, from increasing efficiency in manufacturing processes to improving safety in self-driving cars. They are the key to a more bright future for all of us.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.