Seam tracking sensors are specialized devices comparable to when superheroes share their vision with other people. They allow robots to detect and follow precisely the path that they must use when welding materials to each other. Welded joints are critical specifications for these sensors, and they ensure that the weld is placed perfectly in the joint with the correct heat input. Without these sensors, robots would find it difficult to perform their jobs effectively.

Seam tracking sensors are like a GPS for people to use to navigate. Just as GPS tells us where to go, these sensors guide robots, ensuring that they weld in the right spot. If robots didn’t have these guides to point them in the right direction, they could weld in bad places. This would yield sloppy and weak welds that might fracture under stress. MINYUE laser seam tracking sensor enable the robots to follow the correct path allowing the robot to produce tight and accurate welds every time they weld.

Seam tracking sensors are pretty clever devices. They can also modify the welding tool while the robot is running. That ensures that the sensors regulate how much heat the weld receives. This is helpful as proper heat is vital in ensuring that all gaps or overlaps (where one weld lays on top of another) end up being eliminated in the final weld. MINYUE seam detector sensor allow robots to weld faster and more efficiently Doing this not only saves time but it also helps saves money in the long run.

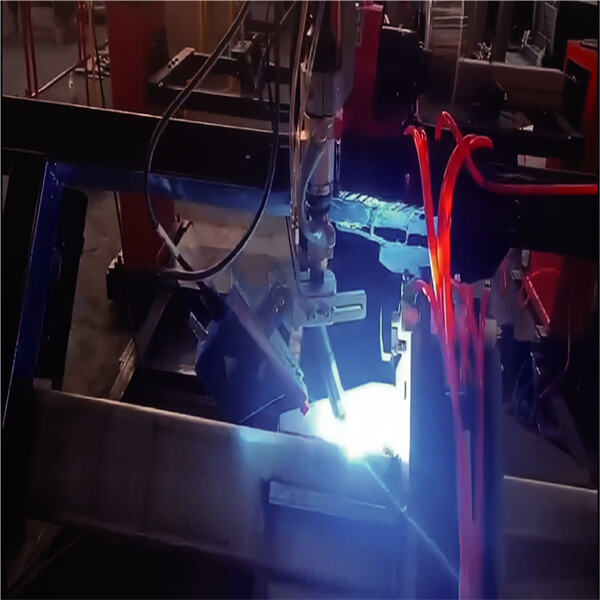

Seam monitoring sensors employ specialized cameras or lasers to scan the seam — the line where two pieces have been joined together. They generate a more precise map for the robot to walk. These sensors are able to observe the seam, for instance, if there are any gaps or misalignment, so they can tell whether things are aligned properly or not. When they identify these problems, they can quickly modify the welding tool to rectify them. MINYUE Advanced welding seam tracker even implement a type of smart technology called artificial intelligence to learn and adjust values to perform well in a wide range of welding applications.

Now that is a great feature; real-time seam tracking sensors. It’s as if to have a or any robot that can think and react itself. That means the robot continuously observes the seam and immediately adjusts when necessary. This allows robots to produce flawless welds without assistance from humans. This is how much helpful to the quality of the welds and also reduces the mistake with the work or minimal chances of redoing the work ultimately saving both time and money. In fact, real-time seam tracking is a game-changer for welding, as it makes the whole process pretty much easier and faster.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.