Hello! Did you know MINYUE has a new cool welding seam tracker? This unique tool is meant to assist welders make perfect seams while they work on their projects. Today we will be discussing how this handy tool can make your weld seems pretty and how it works!

Have you ever observed a well-welded seam? It appears as a straight line, with no lumps, gaps or errors. With the MINYUE laser tracker, yours could be looking that good or better! The tracker also sits on the seam very close to its edge. You stick this onto whatever you are welding and then you can follow along and make sure your seams are nice and even every time. You can concentrate on whatever you are doing and don't worry that you going to make mistakes.

That's hard, and tiring work, particularly when you're having to track a seam over a distance. It can be a bit tricky at times to hold the torch just right. But why do it manually when you can let MINYUE's automation for seam tracking do the work? The brilliant tracker glides to fully track the seam which means you don’t have to work as hard! This takes the stress off the welding itself and lets you weld longer without getting tired. Once again, you save time and use your energy, making your work much easier and more enjoyable by using this tool.

When welding together two pieces of metal, you want your seam to be strong, smooth, and aesthetically pleasing. MINYUE laser seam tracking sensor technology ensures that the weld seam is straight and consistent throughout. This is very critical because you can hold the pieces together better with a strong seam. Your welding projects will not only look professional with this technology but will last, too. That means you can take pride in the work you do, and your projects can endure the ages.

Welded joints need to look perfecto and be strong. A continuation of sewing space that stitches each seam with an identical look and strength so that they all line-up perfectly. The MINYUE robotic welding systems tracker provides control during the welding process, ensuring that every seam is of the same high quality. It also means that every time you complete a welding project, it will have a nice steady wind so that others can be easy to drive the wind.

Today MINYUE's welding seam tracker revolution X-ray welding. From small projects, such as repairing stuff at home, to larger ones, such as building large structures, MINYUE welding automation technology can help you finish the job efficiently and effectively. This tool is revolutionizing welding and making it much easier for welders to achieve the results they want.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

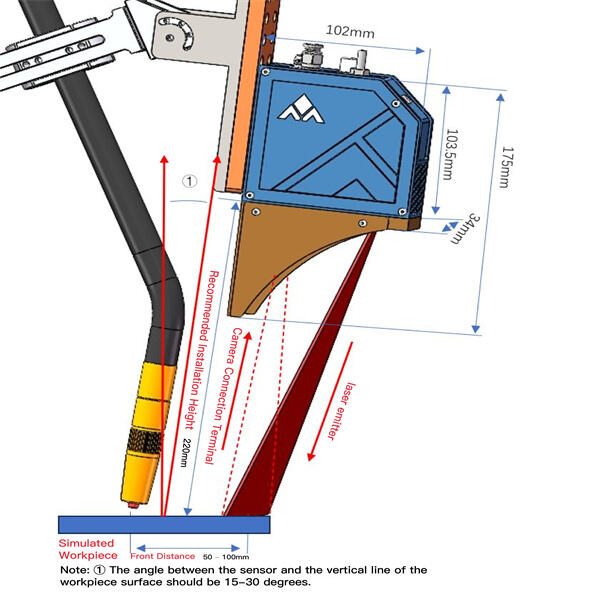

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.