Laser trackers are phenomenal tools that allow us to make extremely precise measurements. They are used by many jobs to calculate the exact location of an object in 3D space. This means that they can tell you precisely where something is and how big it is. Very often, laser trackers are used in such critical areas like construction, manufacturing, and engineering. Laser trackers are handy in these industries to make sure that everything is produced in good order and to the perfect specifications.

MINYUE laser welding robot system have certainly revolutionized how measurements are performed. Prior to the invention of laser trackers, all we had were tape measures and rulers to measure things. This approach was time-consuming, and was sometimes not sufficiently accurate, leading to errors. With fast and accurate measurements thanks to laser trackers. This has simplified the construction of everything from large buildings, to cars to even airplanes. Laser trackers provide workers with the speed and precision needed to help them complete their projects quicker and more accurately.

MINYUE binocular vision camera can be a wide variety of shapes and sizes, but they all operate similarly. It leaves a laser which bounces off a target placed on the object and measure the return beam. By measuring how long it takes for the laser beam to return to the tracker, the device is able to determine the precise location of the object. Depending on whether you have small laser trackers like the one that can be held in the palm of your hand or larger laser trackers set up on a tripod. The laser tracker used can vary depending on the size of the object to be measured.

MINYUE laser welding automation are powerful tools, capable of measuring an object with incredible precision. It can measure distances to a few millimeters, which is extremely precise. Laser trackers, for example, are commonly utilized within the aerospace sector when constructing aircraft. In this realm, a slight error can lead to significant issues, thus precision is crucial. Laser trackers help ensure that workers manufacture airplane components that will mesh flawlessly.

Arrow not only improves the efficiency of laser trackers, but they can also be even more of a powerful resource as technology improves. Laser trackers are becoming better suited for a wider range of jobs as new features are constantly being added. Laser trackers may even be able to measure things more quickly and accurately than they do today. This will allow workers in various industries to perform their tasks even more effectively.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

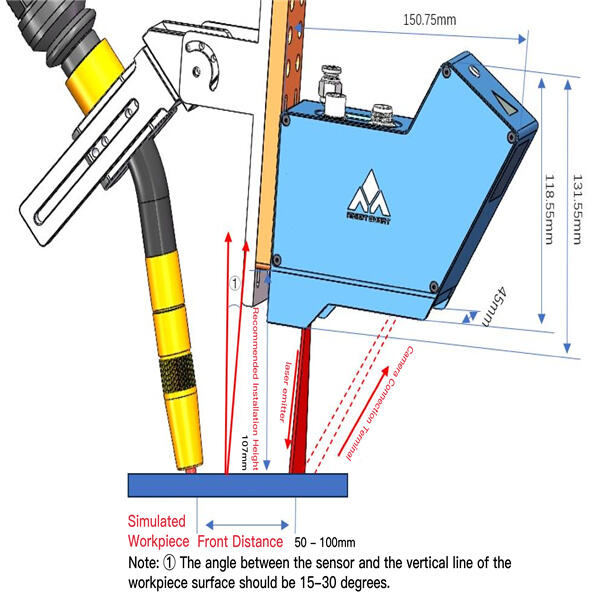

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.