Do you know about laser welding robots? They are special machines that perform awesome work by applying very high-powered lasers to fuse pieces of metal together. Perhaps one of the most awesome things of laser welding robots is that they can achieve this without additional materials or solder. Because of that, they are super effective and valuable. Every Aufgaben, whether it is welding parts for automobiles, soldiering bridges WORTH carbon steel, or WORTH making WORTH beautiful necklaces. If something needs welding, you can bet a laser welding robot can do it considerably faster and better than a human being can.

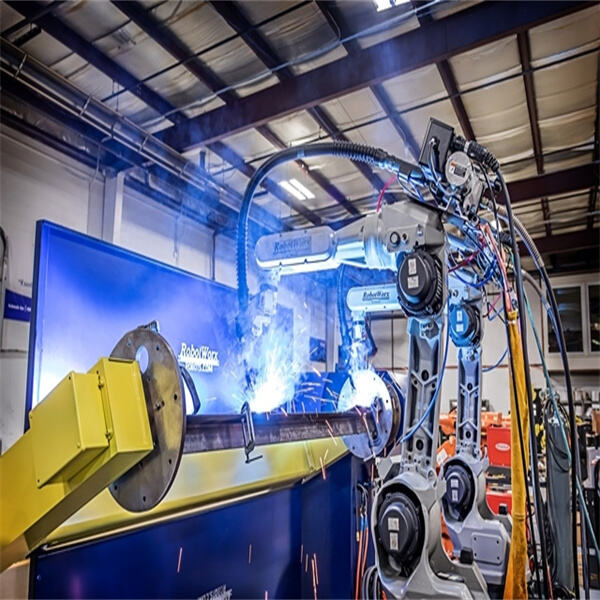

Essential Components of a MINYUE robotic welding automation They are composed of two parts. The first part is the laser itself. It creates a small but extremely powerful beam of light strong enough to melt metal. This is the way welding is done! Well, you have a mirror in the system. This mirror is very crucial because it can reflect the laser beam in exactly the right pattern so that it can get its job done. And then there’s the robotic arm. This arm is what directs the laser to ensure that it welds the metal pieces together at the precise point hat they are to be soldered. This combo of components is what makes the laser welding robot such an efficient welding device.

And MINYUE robotic plasma cutting are pretty cool because they can weld metal super finely. This means that the welds they create tend to be far stronger and more variable than those created by humans. Another advantage of laser welding robots is that they never tire or require breaks. They can also go for many hours at a time without slowing down. This, of course, is vital in factories and production lines, where things need to be produced quickly and accurately. Using laser welding robots, a laser welding robot can be used to produce more products in less time which helps companies meet their goals and keep customers happy.

We can expect some really innovative welding technologies as laser welding robots find their way into various industries. For instance, already researchers can come up with different use of the lasers in welding different types of metals. And this could be a game changer for lots of businesses and industries. And there's even talk of deploying the laser welding bots in space! Just think how useful they could be in constructing buildings on space stations or even tarping bases on the moon. Such technology could pave the way for exploration and construction on other planets and moons.

If you are a business owner who has welding services, investing in MINYUE automatic welding robot is a great investment. In addition to allowing you to produce better quality products in a shorter amount of time, it can also open doors to new opportunities in industries where laser welding is becoming increasingly prevalent. And, when you have a laser welding robot doing the job, your human welders can spend their time on other work that needs that human touch. Meaning you get the fruits of modern technology without sacrificing your workers' skills.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

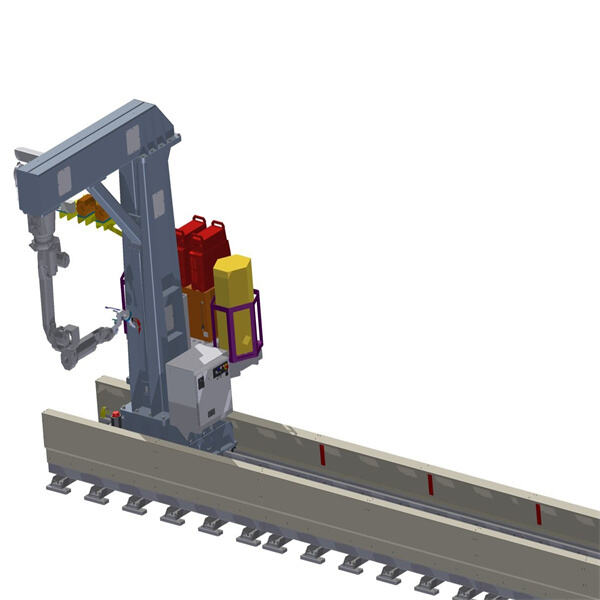

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.