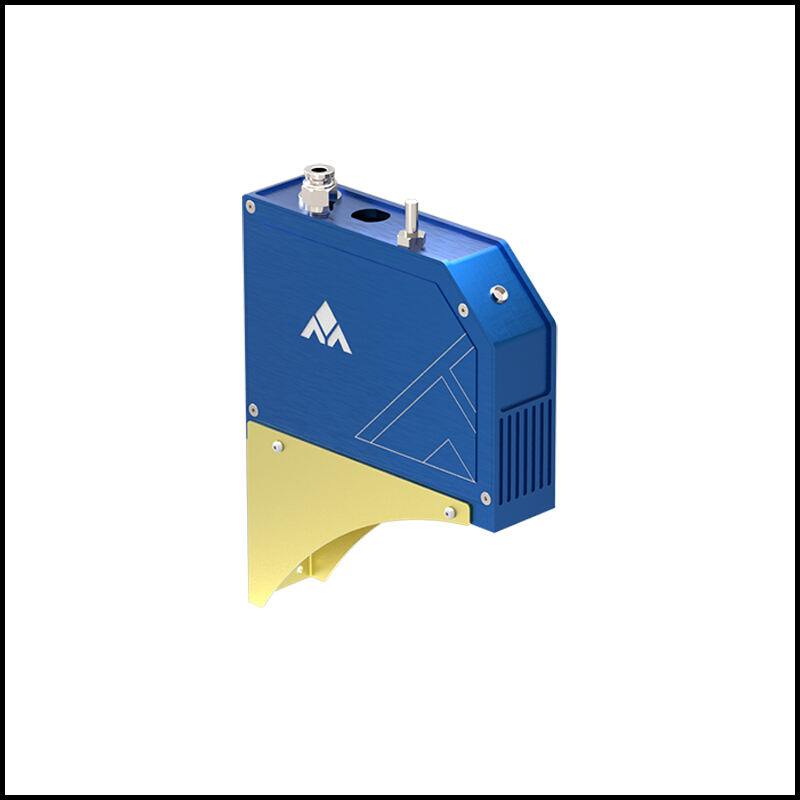

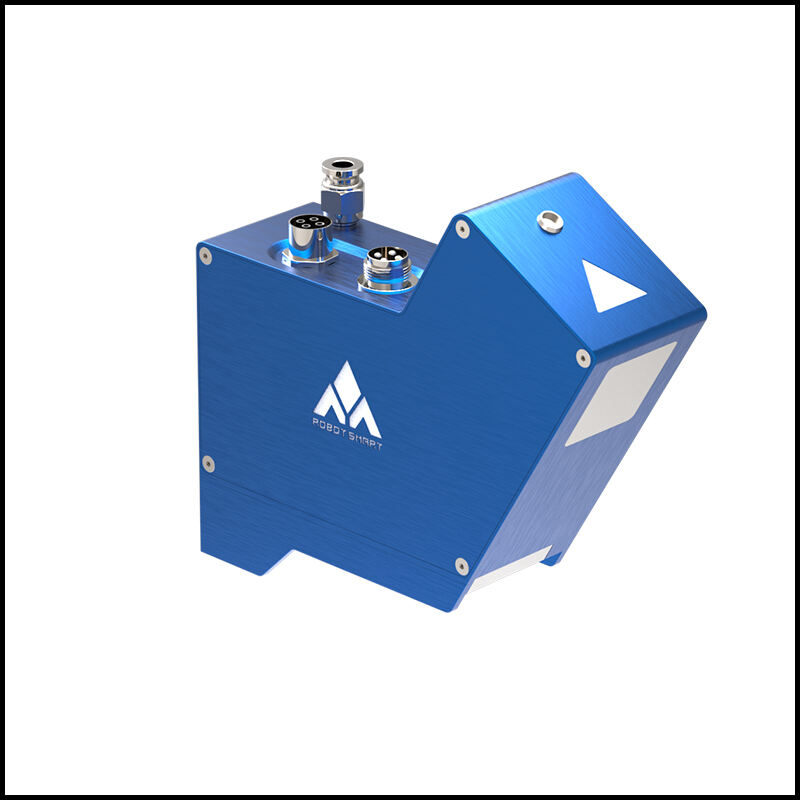

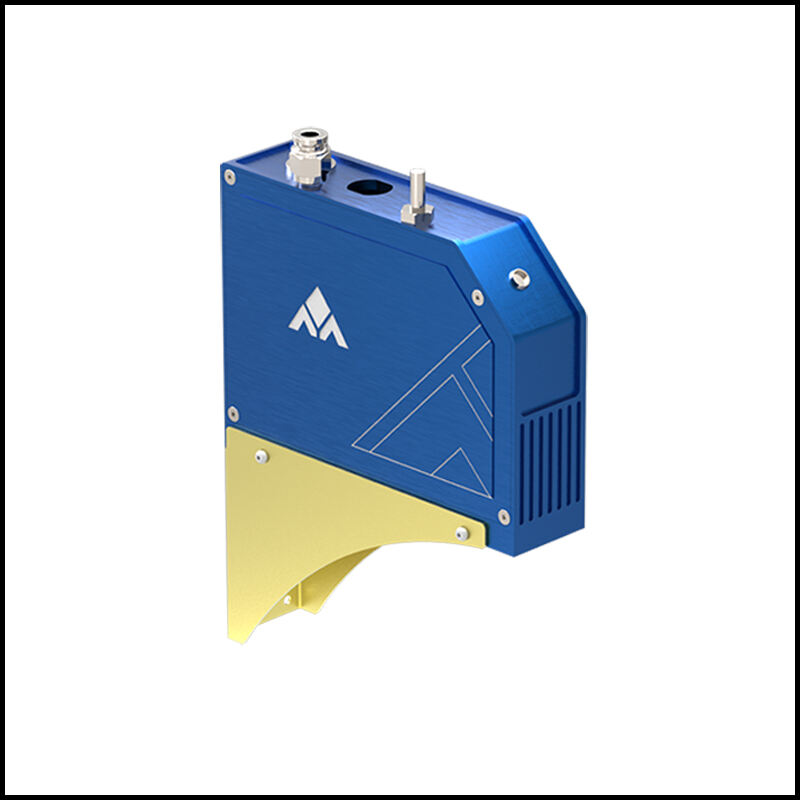

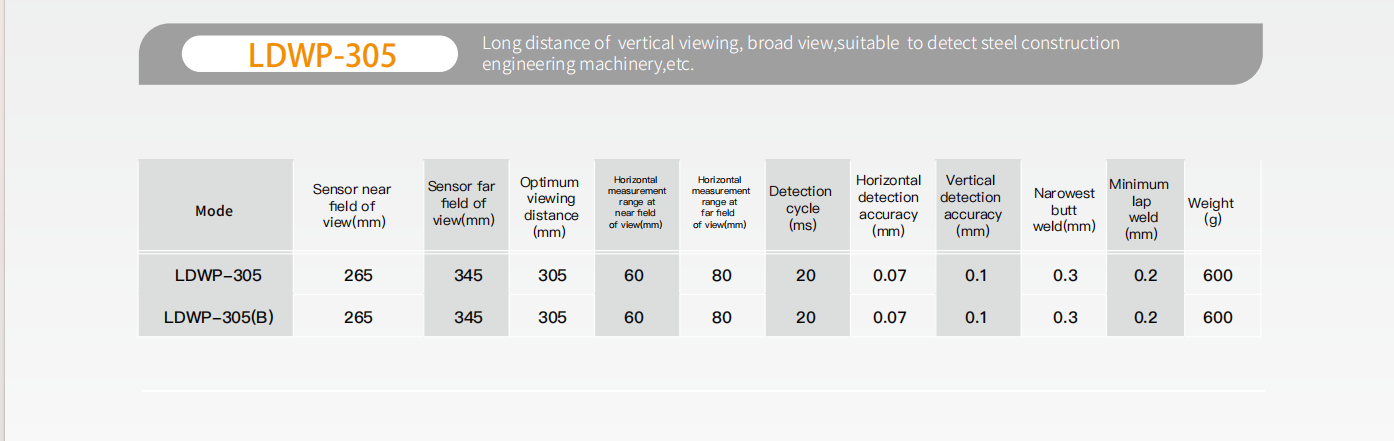

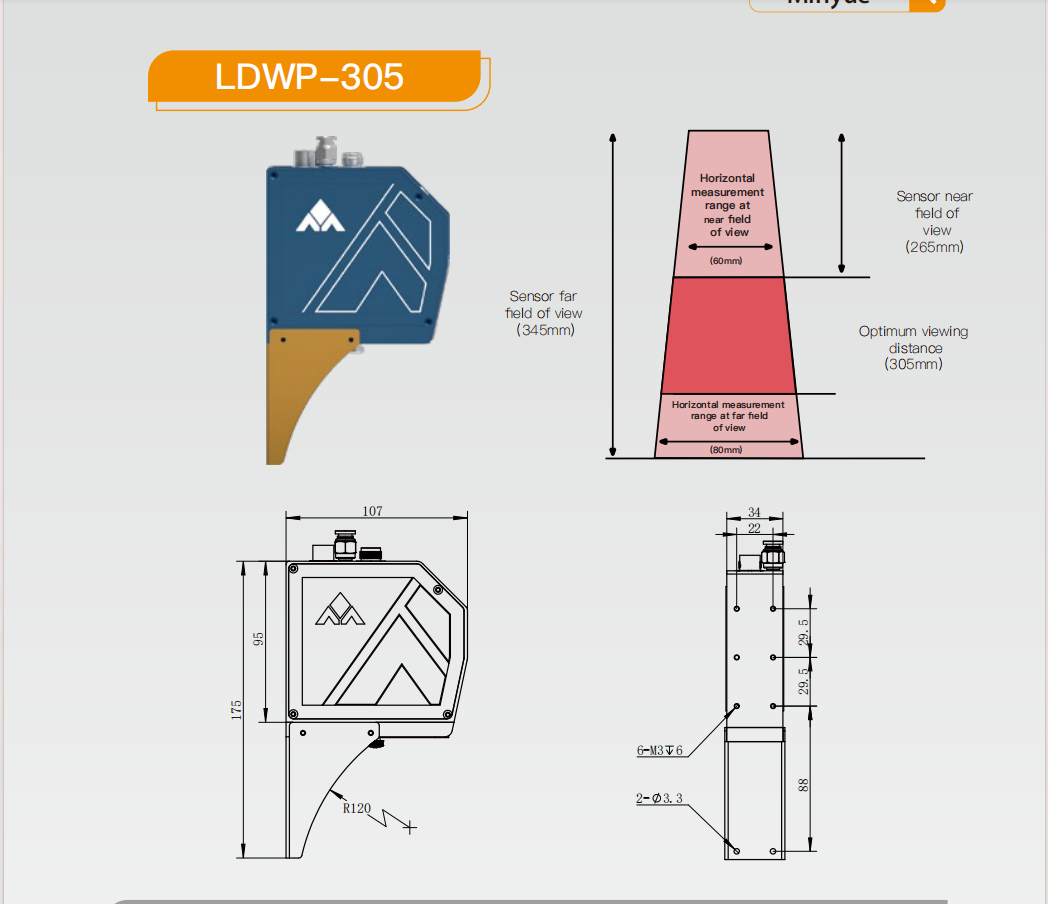

LDWP-305 seam tracker

The new generation of seam Tracking Sensor through the new MINYUE architecture upgrade to greatly improve the basic performance, and combined with the needs of market users, targeted division, to provide users with a comprehensive product line from basic application to high-end expansion.

- Overview

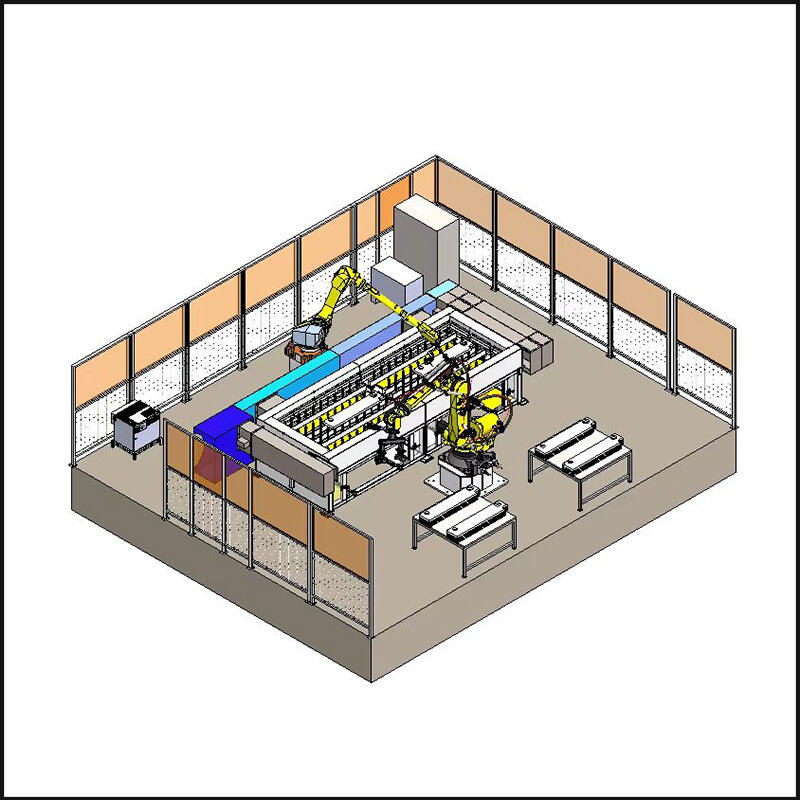

SmarEye WR laser seam tracking system is a 3D laser vision system for robotic welding developed by Beijing Minyue Technology Co., LTD. It supports robot brands such as KUKA, Yaskawa, ABB, Fanuc, Kawasaki, Siasun, Guangshu etc . The system consists of three parts: laser sensor, control host and software.

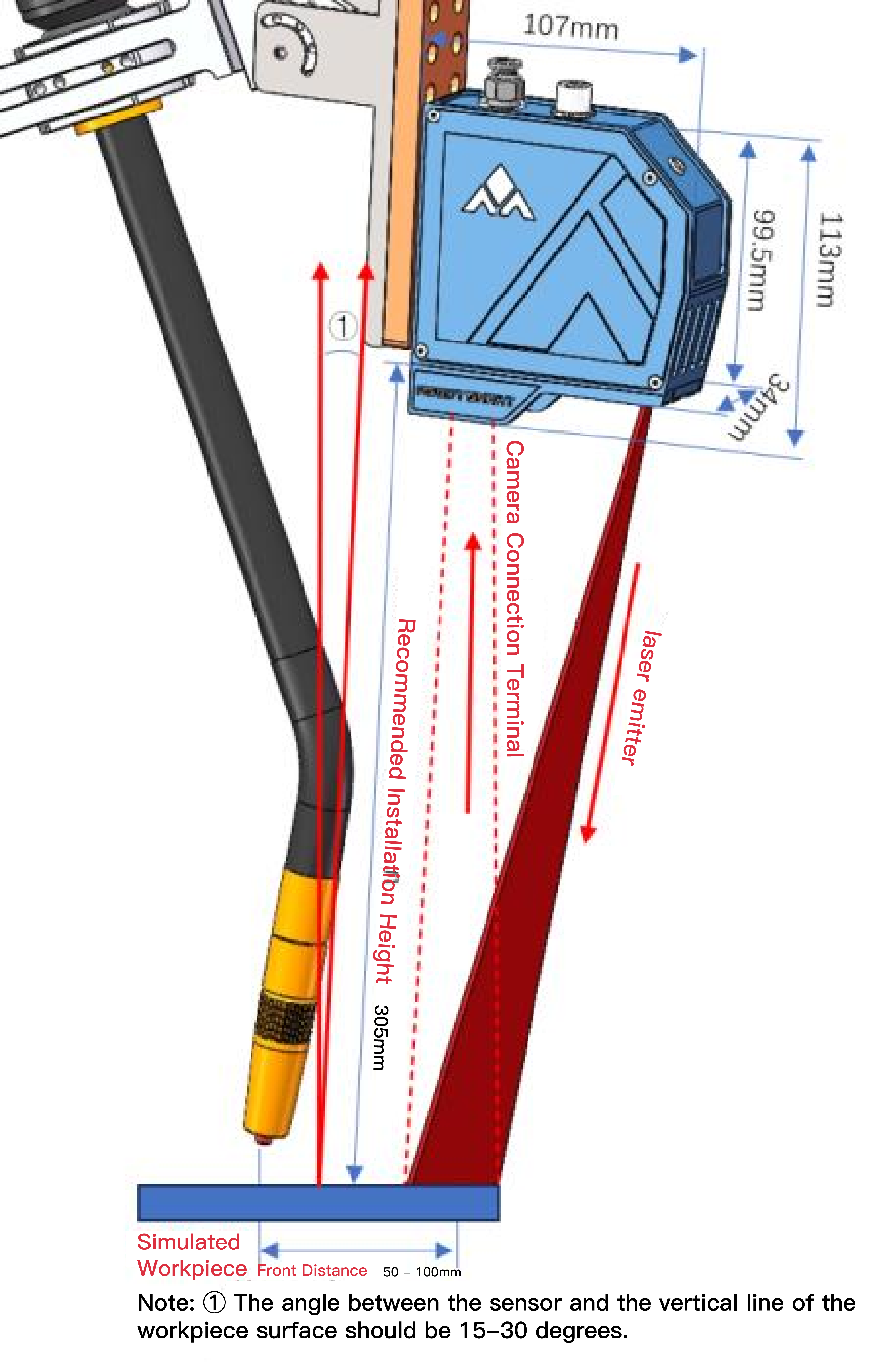

· Laser sensor is used to collect data

· Protective glass is used to protect optical lenses

· Fixed holder is used to install the laser sensor on welding torch

· Control host is used to configure and control laser sensor operation

· Communication cable is used to connect the sensor to control host

· Protective shield is used to protect sensor from arc light and splash.

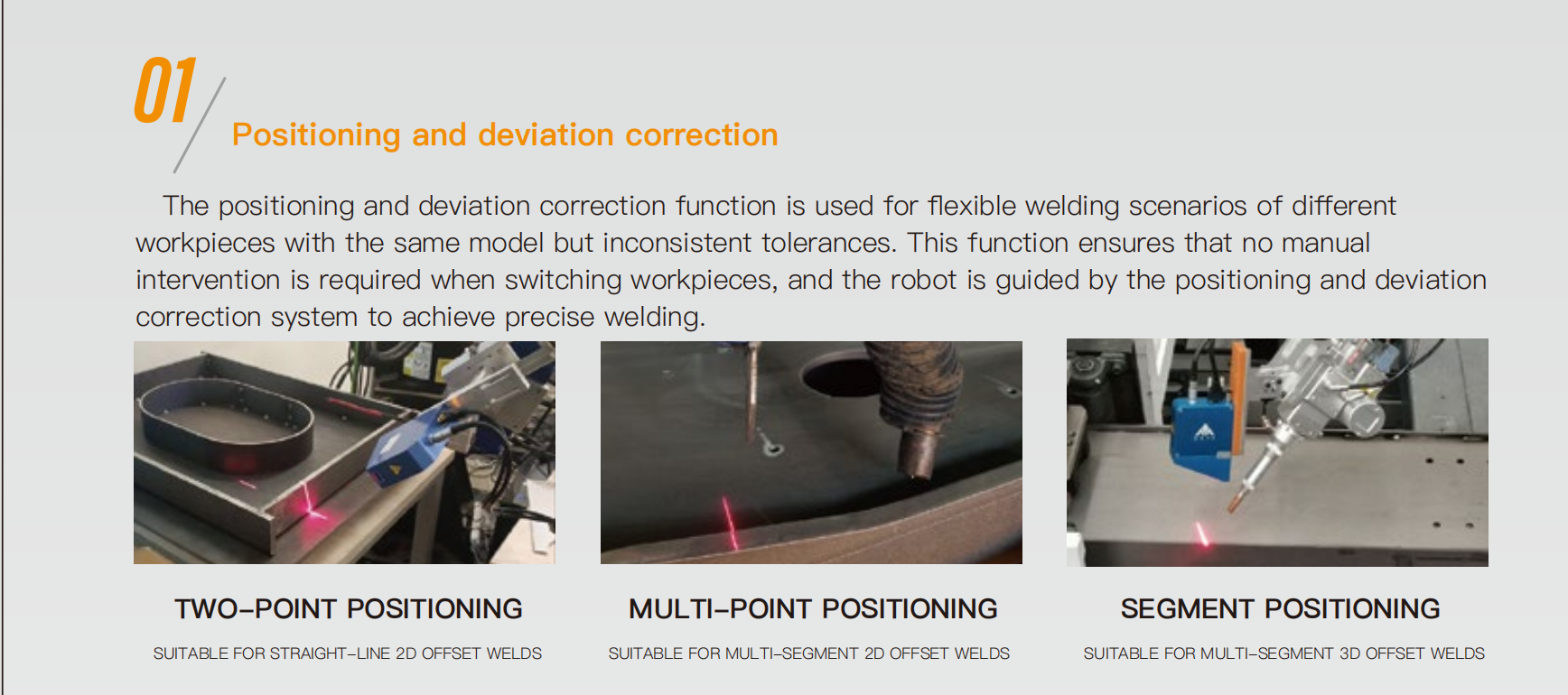

Optical seam tracking is suitable for automated joint seam detection, e.g., welding or gluing processes. By using measuring lines, the component's position is detected, and the precision of the seam tracking is improved.

FUNCTIONAL DESCRIPTION

The robust LDWP-305 triangulation sensor is designed for industrial use, even with highly reflective materials. The sensor scans the joint without contact and transmits the seam position, the gap size, the edge offset and the orientation of the tool relative to the component surface to the robot control.

The sensor is suitable for the most demanding applications,as it is insensitive to stray light, water and dust (IP67) and immune to electromagnetic radiation (EMC).

Please select the type reasonably according to the actual scope of application, to avoid workpiece collision sensor, robot load generally normally need 20KG .

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK