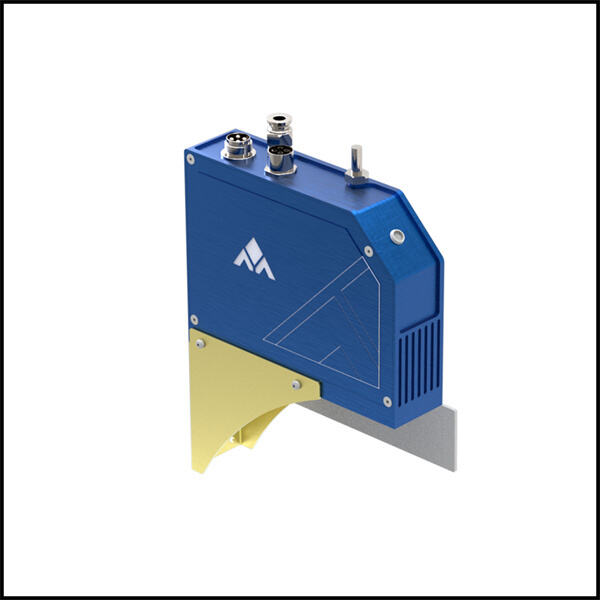

Seam Renegade — Stab sensor

When talking about production, we can only imagine one of the most amazing devices that helps to sew in a proper way — Seam detector sensor. They are essential for many industries. So let’s find out a little more about how these sensors work and why they’re so useful.

Seam detector sensors are specialized sensors that ensure two optical lenses are perfectly aligned. Pretend you are creating a puzzle. Every piece has to fit tightly with the others. Big data is like a jigsaw puzzle, if there is a gap or it does not fit, the puzzle will not look nice. MINYUE laser seam tracking sensor work in much the same way. They emit small signals to determine whether the seam, or joint, between two pieces appears smooth and free from errors. Consider these sensors as tiny detectives. They identify problems and help make sure things are made correctly, like a detective finding clues to solve a case.

Seam detector sensors play a crucial role in manufacturing quality control. Once products are produced, they then require to be assembles accordingly. If anything seems out of order, problems will arise on in future. These MINYUE seam tracking sensors are used to do a verification on whether products are built correctly, and in case there are mistakes. With the help of these sensors, factories are able to maintain the highest quality of what they produce and provide people with a safe product to use. So when you purchase something, you know that it is made properly and will perform correctly. We will all want to feel safe and happy with the things we buy, and these sensors contribute towards that.

There are also a lot of applications in different industries of welding seam tracker in ensuring good quality products. In the food industry, for example, these sensors inspect seals on food packages. This means they shut tightly so the food inside does not go stale or bad. In the auto industry, sensors examine seams on cars. This is super important because cars have to be strong and safe for people to drive. These sensors serve to help ensure products are made properly and that the items people purchase are trustworthy. Seeing these sensors in action, we can feel more assured that we are protected by them.

Seam detector sensors function using advanced technology that allows them to scan for defects in seams. They have sensors that emit signals to see whether things are assembled correctly. It’s a bit like a game of “Simon Says,” where the sensors are always carefully listening. The sensor will indicate a need for adjustment, if there is an error. This technology ensures that products are manufactured accurately and without error. These advanced capabilities help businesses identify issues early, and address them before the products reach the product completion stage. Well this means overall better quality.

MINYUE Seam detector sensors are significant in detecting any defects in the products. They ensure that everything is assembled correctly and with no mistakes. With the use of these sensors, companies can have greater confidence that their products will be high quality and safe for people. That means everyone can assume what they purchase is produced to satisfaction. Like a collection of nets that will catch you before you fall too far.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.