No Programme, intelligent Bevel cutting of extra-long curved workpieces, one click solution.

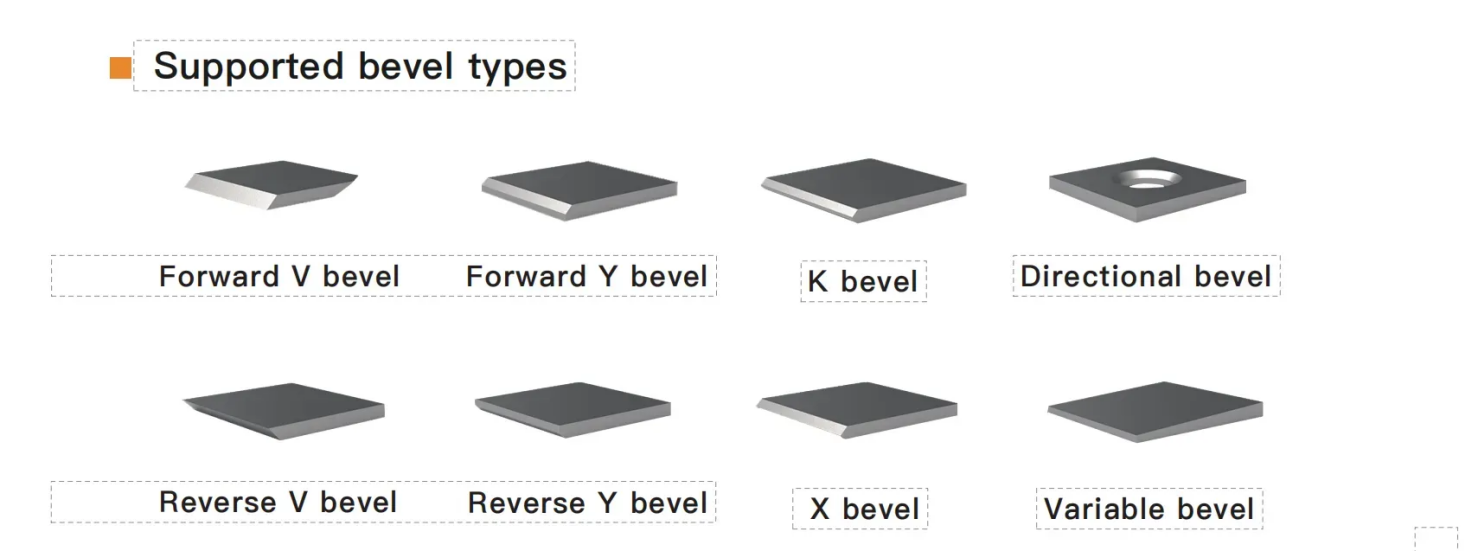

The beveling process originates from the welding demand and is a necessary process before welding of 8~120mm thick steel plates, which is widely used in industries with high market concentration such as coal mining machinery, engineering machinery, construction steel structure, shipbuilding, pressure vessels, and so on. Beveling cuts a wide variety of workpieces, small batches, low degree of standardization, and the cutting needs to be compensated for torch height, cutting speed and slit offset.

The size and type of workpieces for hydraulic supports varies widely, requiring the machining of 100~800 beveled workpieces with different specifications.

Traditional manual cutting: the required fixtures and jigs are difficult to be adapted to a wide variety of workpieces, especially shaped parts with rounded edges,Strong dependence on workers' experience.

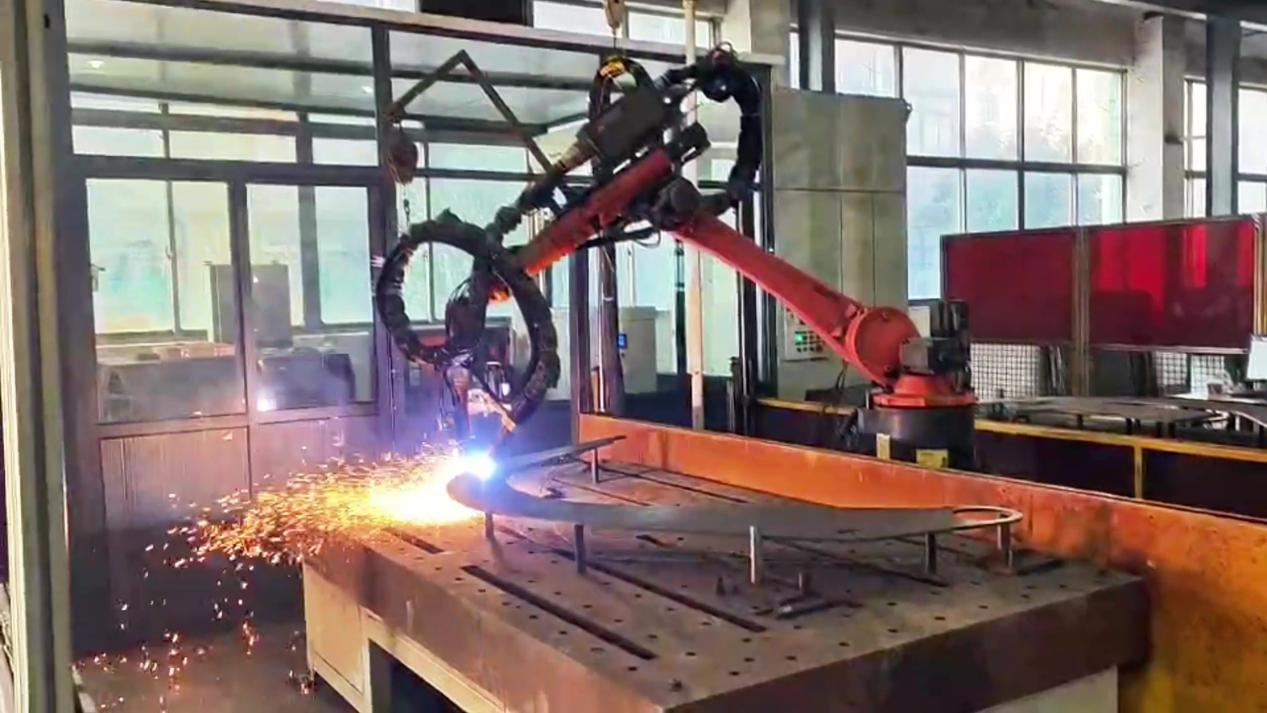

Robot bevel cutting: manual teaching is cumbersome, need to stop, low utilization rate of robot.Multi-species, small batch, large deviation of incoming materials, frequent change of production.

Difficulty of workpiece positioning: traditional workpiece positioning using limit pin, different types of workpiece pin arrangement position are different, process experience is highly dependent.

Extra-long workpiece lengths of 10 meters or more require expensive tooling and fixtures to ensure accuracy.

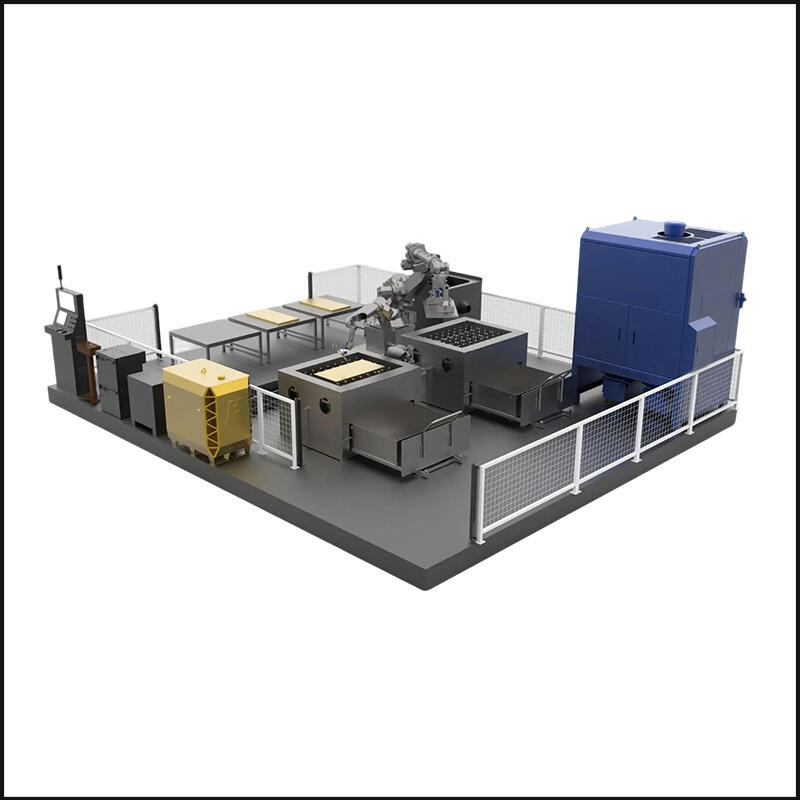

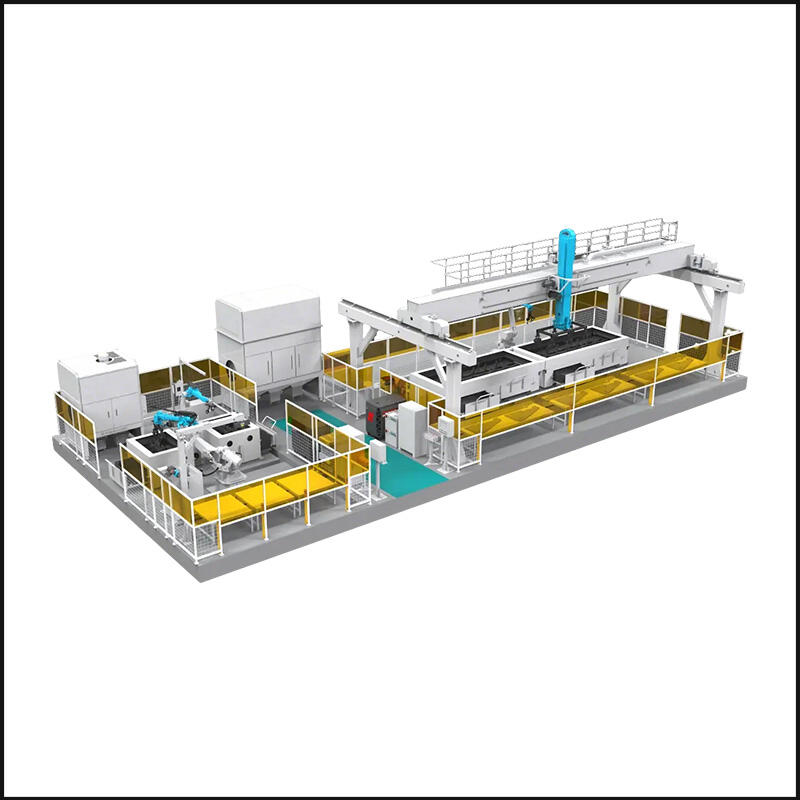

MinYue technology for a head of coal machine manufacturing enterprises to provide medium-thickness plate beveling robot cutting intelligent solutions.

1、It takes 30-40 minutes to program a workpiece by manual teaching, but only 2 minutes by RobotSmart-intelligent decision-making platform of MinYue Technology, and the drawing is imported in batch to generate the beveling parameters quickly.

2、It takes 5-10 minutes to position the workpiece manually, but now it is placed at will. Positioning by SmartVision-3D vision system saves time for loading and unplugging limit pins. Loading and unloading is easy and convenient.

3、Multiple workstation configuration, matching different production modes, combined with loading and unloading robots, dual-machine coordination, realizing 24-hour non-stop work of robots, capacity pulling full.

4、Intelligent solution specially built for ultra-long workpieces, maintaining high quality and precision while processing large-scale workpieces, which can meet the machining of ultra-long workpieces involved in hydraulic supports with specifications of 8-10 meters, covering intelligent process libraries such as plasma, flame, etc., and supporting positive and negative V, positive and negative Y, X, K, gradient and other types of bevels.

5、SmartEye - Laser vision tracking system line laser positioning, cutting trajectory tracking, cutting blunt edges optimization can be guaranteed at +/-0.5mm.

6、Originally, an experienced worker to operate a robot, now a general worker can watch 3 robots or more at the same time, the overall production efficiency increased by more than 60%.

It truly realizes one-button start cutting, starts production in 2 minutes, completely No Programme

high efficiency and high precision.

World Leading Intelligent Manufacturing

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK