- Overview

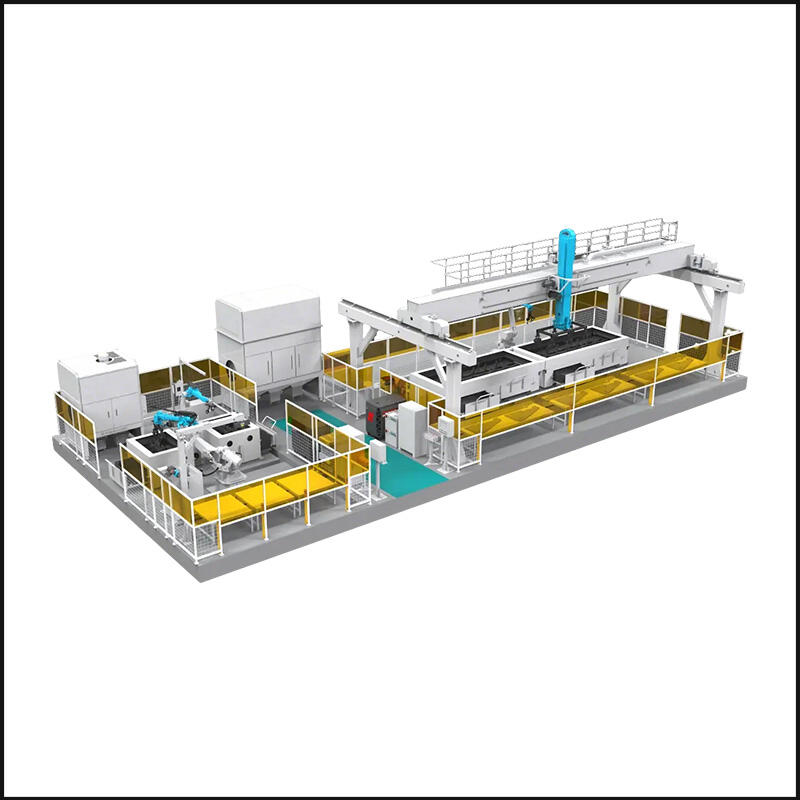

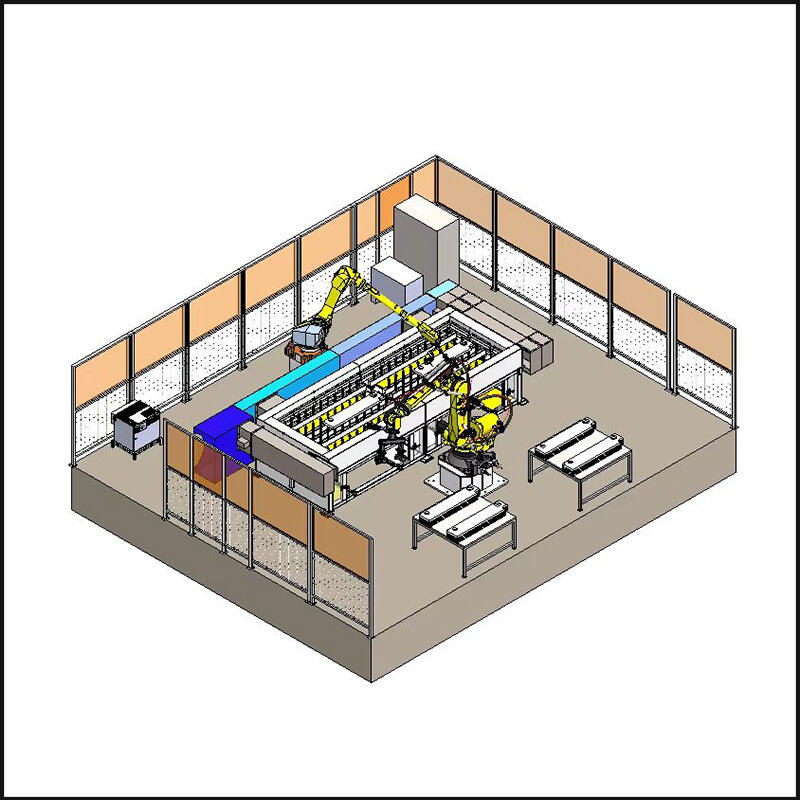

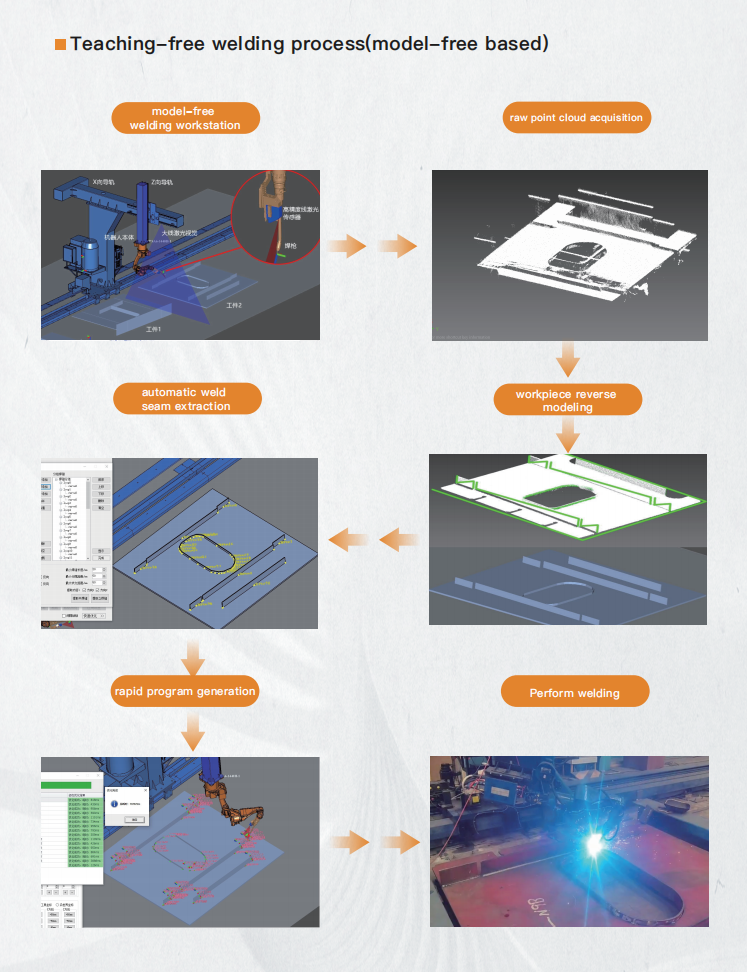

MINYUE Technology non-teaching intelligent welding control system has been engaged in the field of robotic welding automation with years of experience. For solving the industry pain point. Such as escalating welder shortage ,inadequate precision of parts unloading and assembly, a large number of non standard and small quantity work piece needs in steel construction, ship building, heavy industry ,manufacturing etc. It offers the intelligent welding solution featured by full integration and teaching free advantages .

Non-Teaching welding system

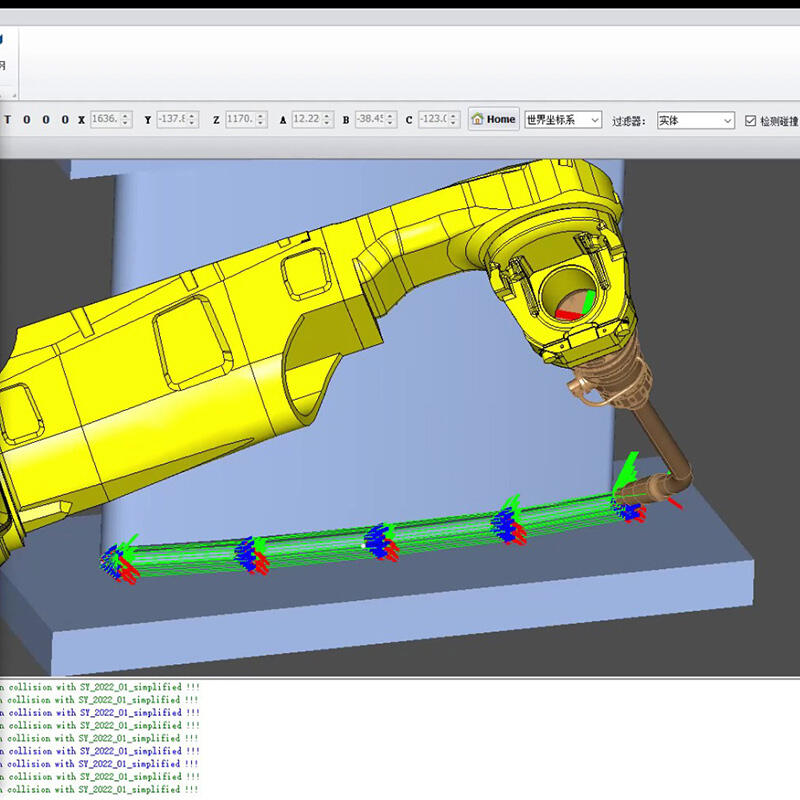

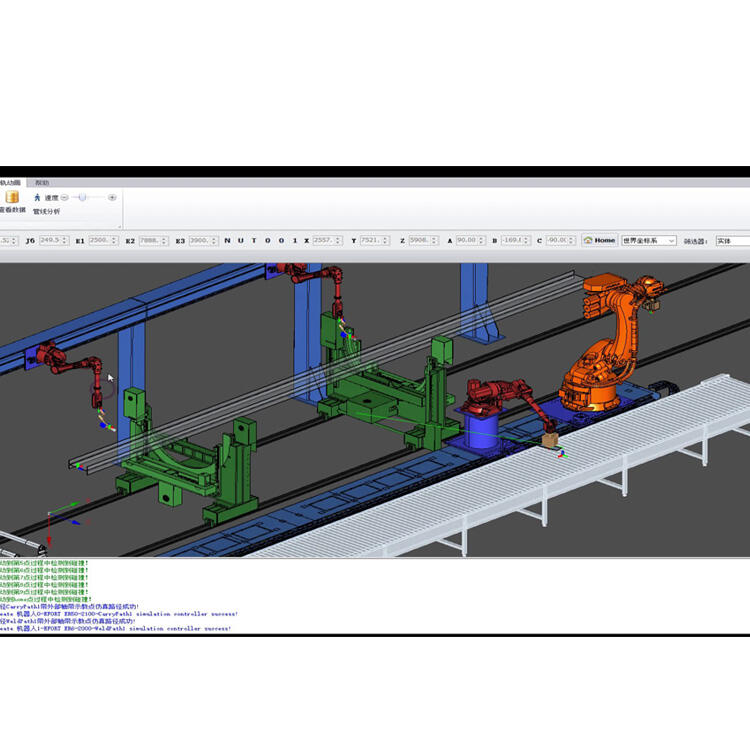

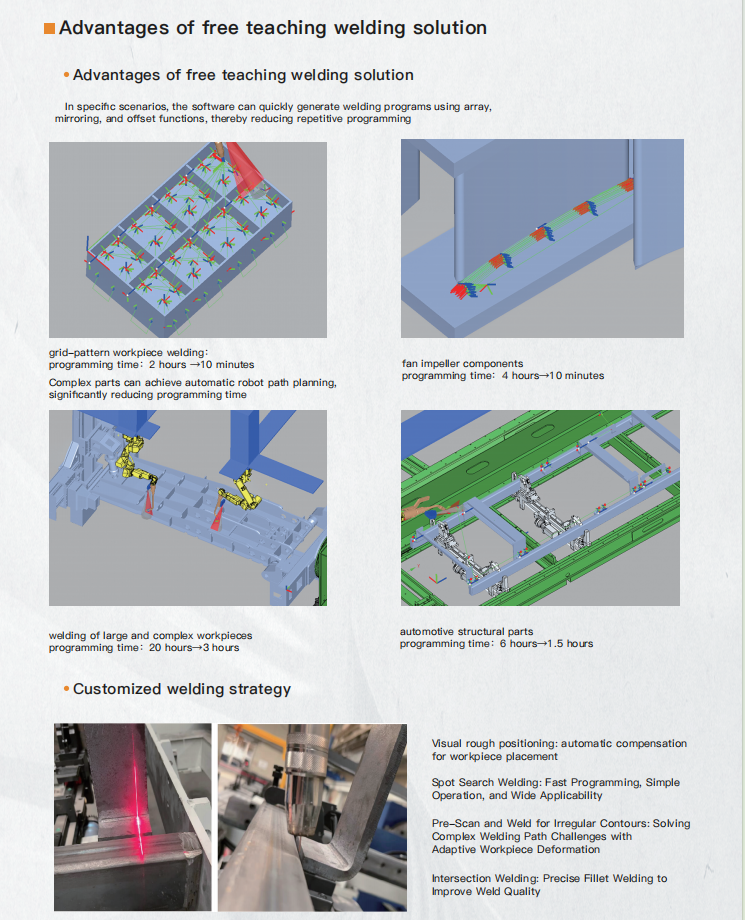

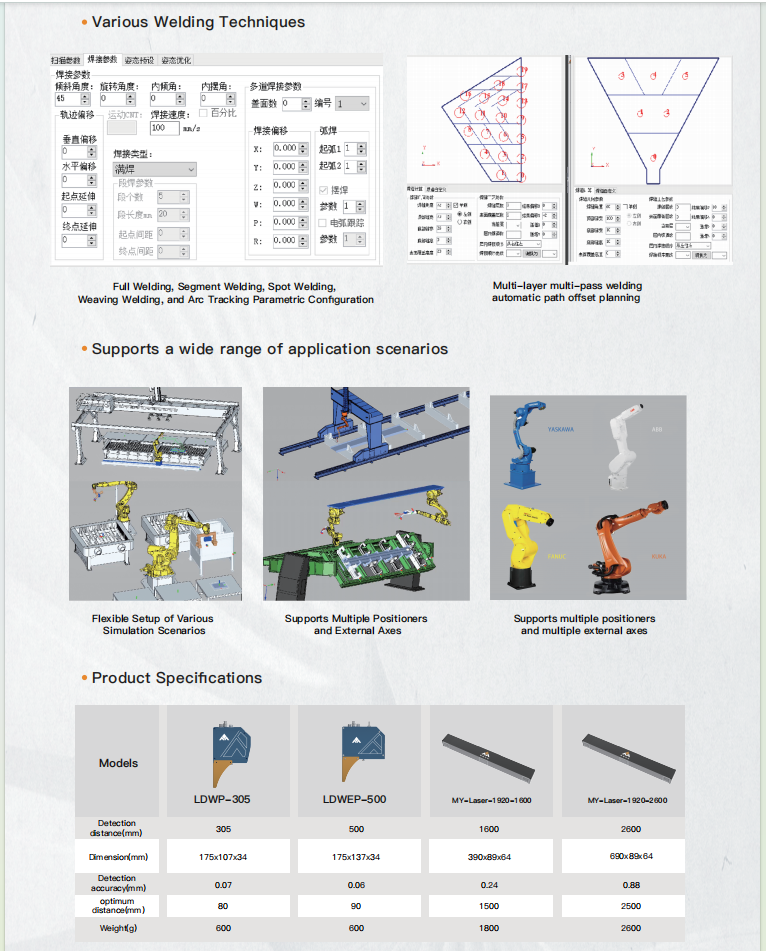

The Teaching-free welding system supports major robot brands, including KUKA, FANUC, ABB, and Yaskawa, as well as domestic brands like Siasun, Estun, and Efort. By integrating the self-developed SmartEye laser vision The non-teaching welding and cutting system consists of an intelligent decision system (RobotSmart), a laser vision tracking system (SmartEye) and a large-view vision modeling system (SmartVision).Through the collaboration between the three system, By importing 3D drawings into the RobotSmart offline programming system,Generating of robot welding trajectories (including scanning points, welding points, welding instructions, etc.)Reverse modeling of workpieces with the SmartVision system's large line scan camera。Precise positioning of weld seams by laser vision sensor of SmartEye system.Realizes non- teaching automatic welding of the current workpiece.

It helps manufacturers overcome the challenges of high programming complexity and low levels of automation, while also meeting the welding production requirements for small batches and different types of workpieces, thereby improving processing efficiency and product yield.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK