- Overview

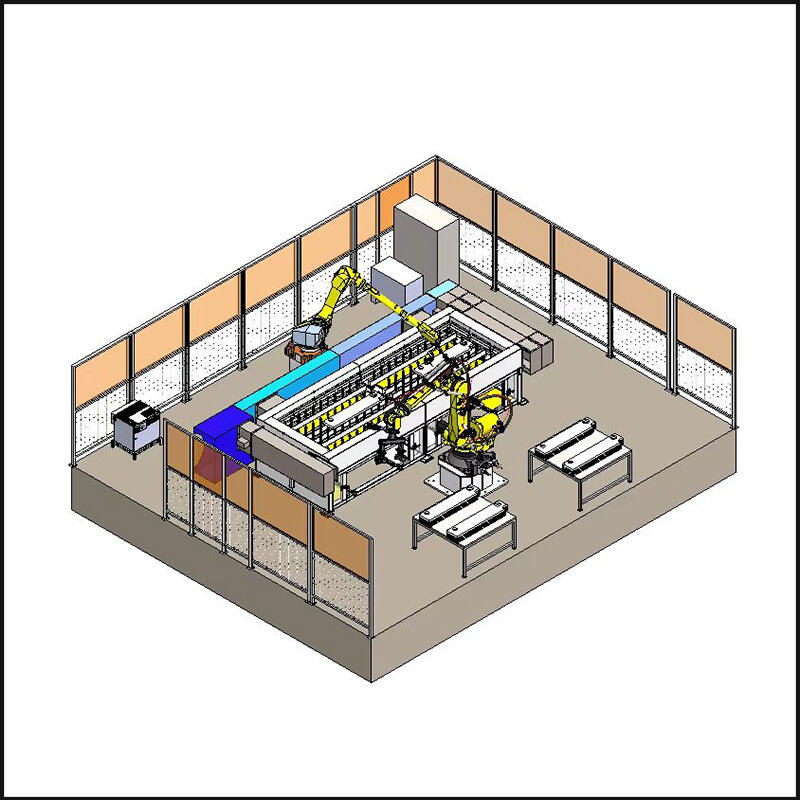

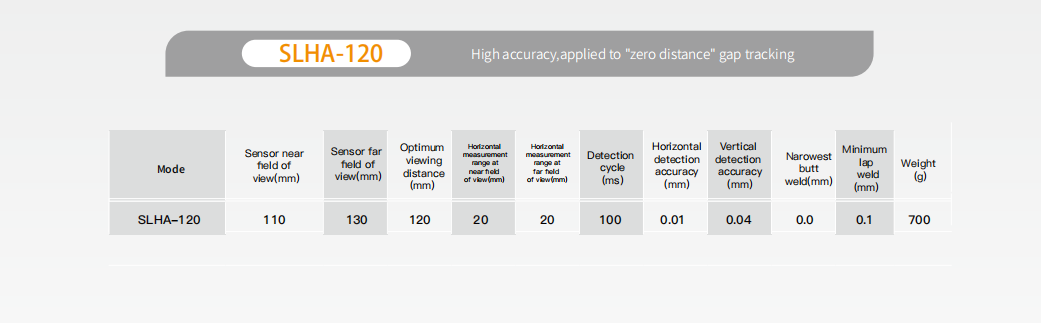

Optical seam tracking is suitable for automated joint seam detection, e.g., welding or gluing processes. By using measuring lines, the component's position is detected, and the precision of the seam tracking is improved.

FUNCTIONAL DESCRIPTION

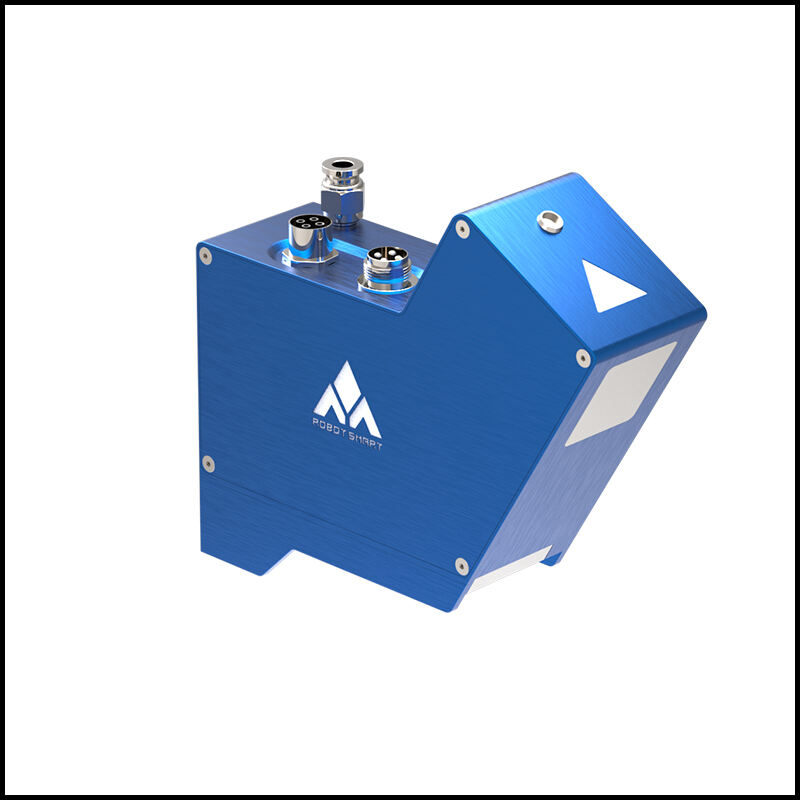

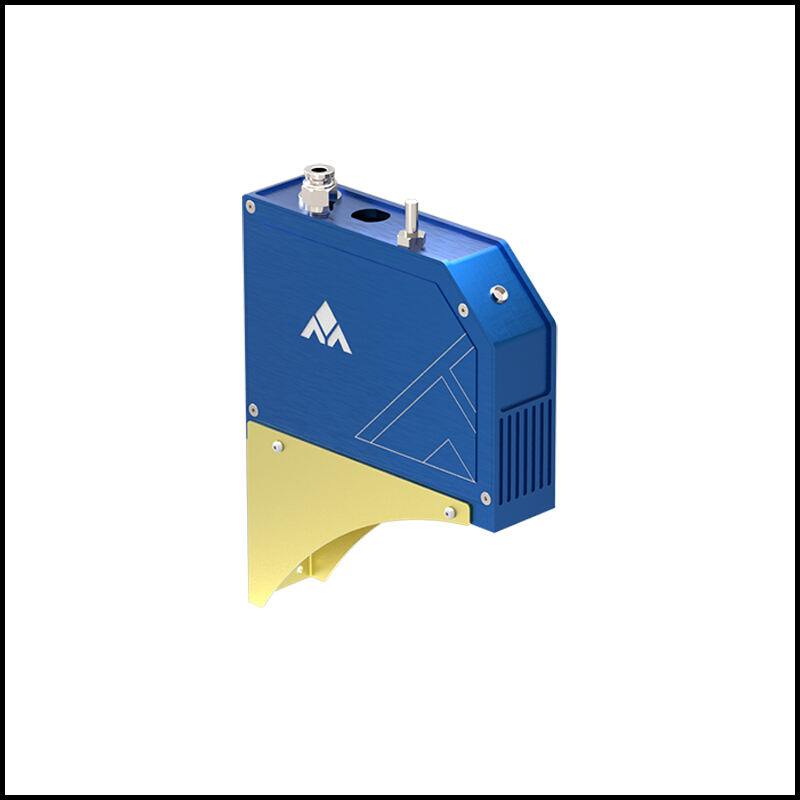

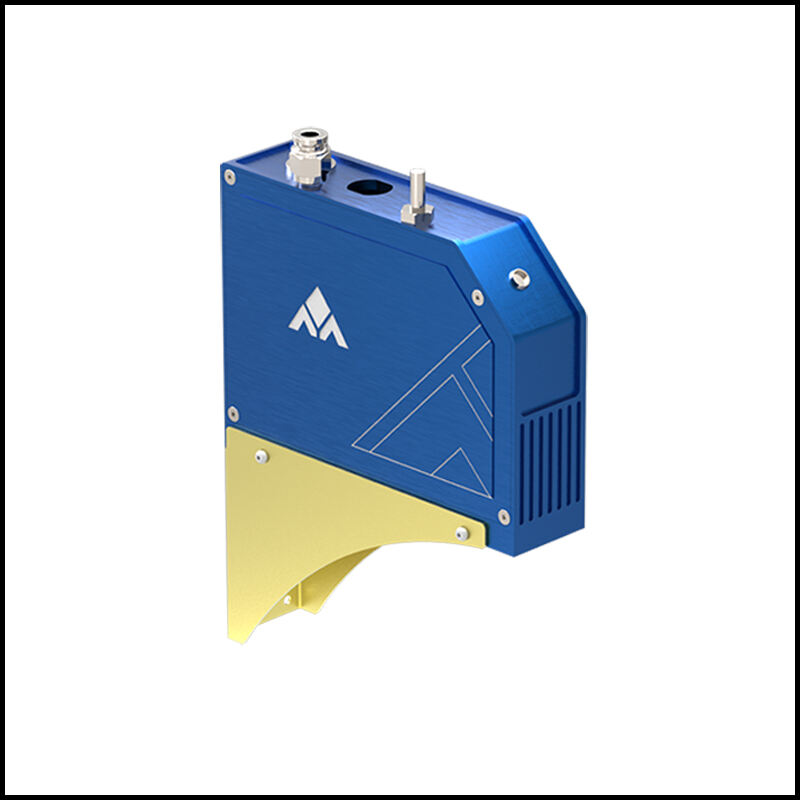

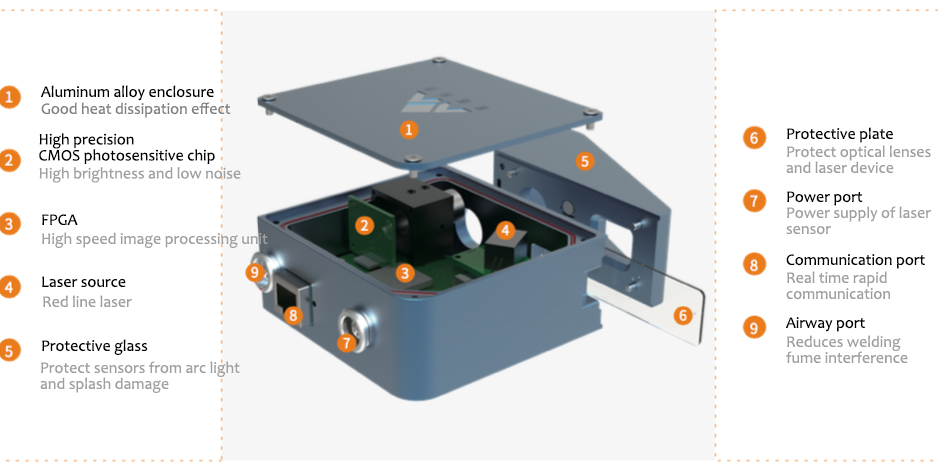

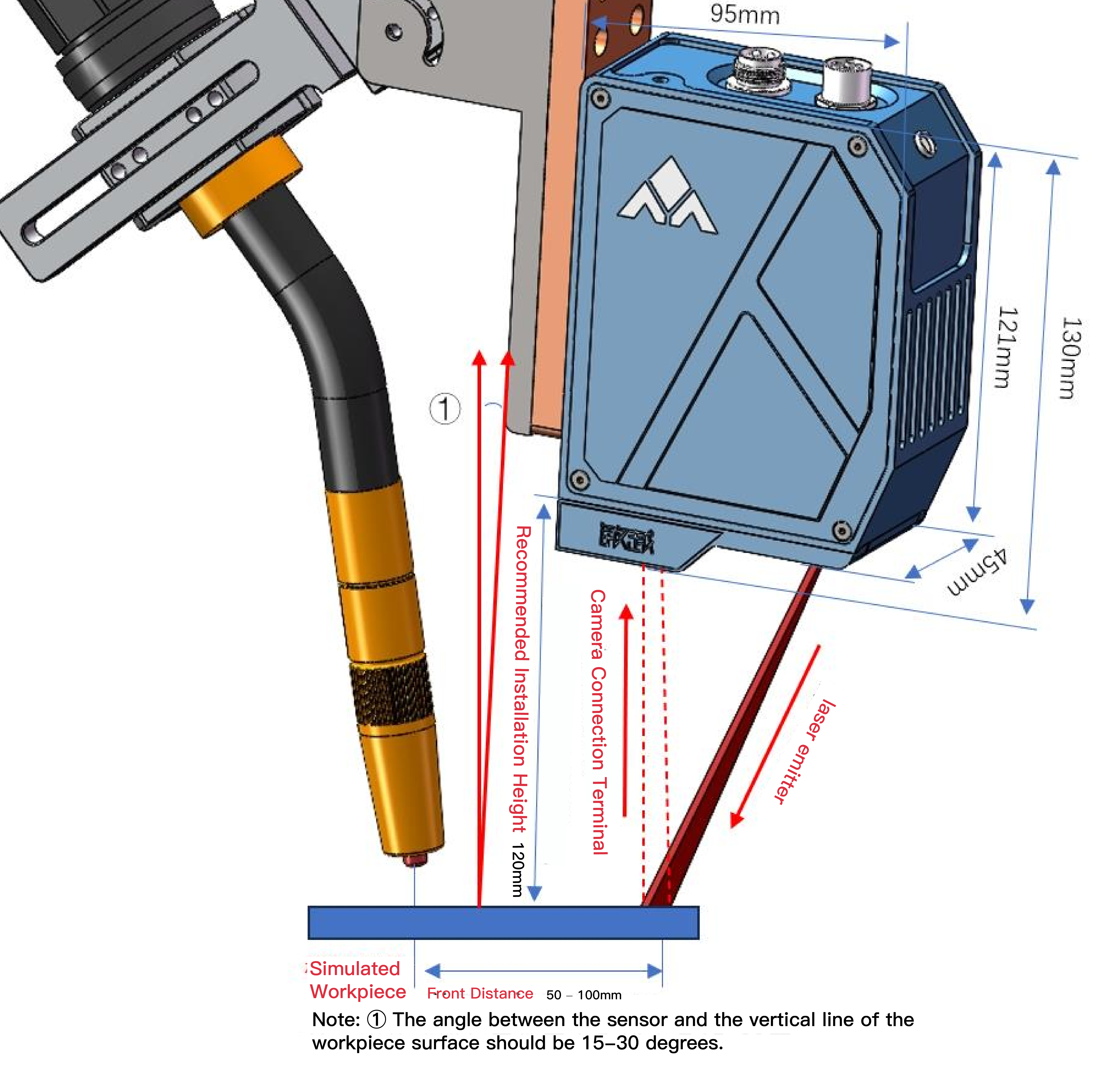

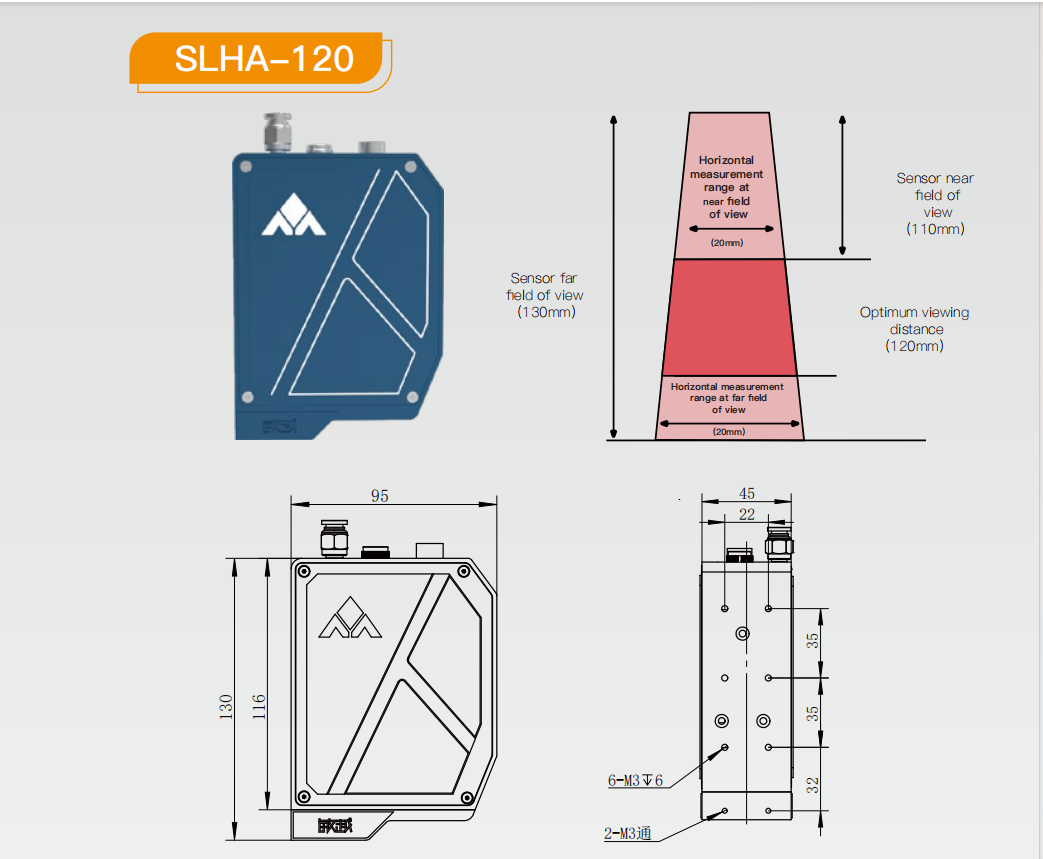

The robust SLHA-120 triangulation sensor is designed for industrial use, even with highly reflective materials. The sensor scans the joint without contact and transmits the seam position, the gap size, the edge offset and the orientation of the tool relative to the component surface to the robot control.

The sensor is suitable for the most demanding applications, as it is insensitive to stray light, water and dust (IP67) and immune to electromagnetic radiation (EMC).

APPLICATION AREAS AND INTERFACES

• Automated production processes such as welding, gluing,etc.

• Interfaces to all standard robot controls and portal systems are available

BENEFITS

• High process reliability through the use of the latest camera technology

• Suitable also for reflective materials such as stainless steel and aluminum

• Highly reliable measurement data capture through measurement lines

• Protective glass quick-changer makes it easier to replace the protective glass

• Air and water cooling integrated into the sensor

• Easy to use

Please get in touch with us for individual solutions if these features do not meet your requirements.

Please select the type reasonably according to the actual scope of application, to avoid workpiece collision sensor, robot load generally normally need 20KG .

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK