Ადამიანები უკვე ძველიდან ხარისხობდნენ — მაशინების წინააღმდეგ. წლების განმავლობაში ყველა ხარისხობა ხდებოდა ხელით. მაგრამ რობოტების ჩასატარებით, ხარისხობა საკმარისად გაიარა. მათი მოქმედების დროს, რობოტული ხარისხები განვითარეს საფუძვლებიდან, ერთმანეთზე მოცული დავალებების მანქანებიდან, სასურველად განვითარებულ, მაღალად ინტეგრირებულ ამოხსნებად, რომლებიც შეძლებენ ერთდროულად რამდენიმე მűსავალი შესრულებას. ისინი შეძლებენ აAPTER-ების განსხვავებულ მასალების ხარისხობას ერთდროულად და არ მართლაც შეძლებენ წარმოუხედავად სოციალურად საშიში ადგილებზე წასვლას. ავტომატური საკერძო რობოტი

Საკერძო რობოტები შეძლებენ უწყვეტ სამუშაო განახლებას, რაც ერთ-ერთი ყველაზე გასასიამოვნებელი რამეა. საწვავი, საწვავის შესაბამისად, უნდა შეძლოს შეძლების შემდეგ. რობოტები შეძლებენ უწყვეტ სამუშაო განახლებას უწყვეტოდ ავტომატური რობოტული საკერძო

Საწყისში, ველდინგ რობოტები დახმარება ბიზნესებს ფულის შენახვაში გრძელ ვადაზე. პირველ რიგში, ველდინგ რობოტის ღირებულება შეიძლება ჩანაცვლებით გამოიყურებოდეს ძალიან გავრცელებული. მაგრამ დროის განმავლობაში, თუ კარგად შეხედავთ, ისინი საბოლოო ღირებულებაში საკმარისად საბარია. ველდინგ რობოტების გამოყენება რობოტული სველის მოწყობილობები продажი

Ტექნოლოგიური პროგრესის განმავლობაში, ველდინგ რობოტებიც უწყვეტლად გახდებიან უკეთესი. ისინი უფრო და უფრო მეტი სარგებელი დავალება შეძლებენ განახლება. ზოგიერთ ველდინგ რობოტზე სენსორები, მაგალითად, ახლა უკვე შესაძლებელი ხდება ისინი სამუშაოში გამოიყენონ

Ერთ-ერთი უკეთესი ფუნქცია ველდინგ რობოტებისაა ის, რომ ისინი ზუსტი და ეფექტური არიან. ისინი შეძლებენ ზუსტ ველდების შესაქმნელად, რაც ნიშნავს, რომ ყოველი პროდუქტი ერთნაირად და მაღალ ხარისხის არის შექმნილი. ეს ერთსამართლო ძალიან მნიშვნელოვანია, რადგან მინიმიზებს რისკს

Სწრაფი, ზუსტი, მთლიანად პროგრამირების გარეშე, მაღალი ეფექტიურობა და ზუსტება. ის ამოხსნის تقليს რობოტების სირთულეად სწრაფ პროცესს და შენახავს სწრაფი პროცესის ჩათვლის დრო.

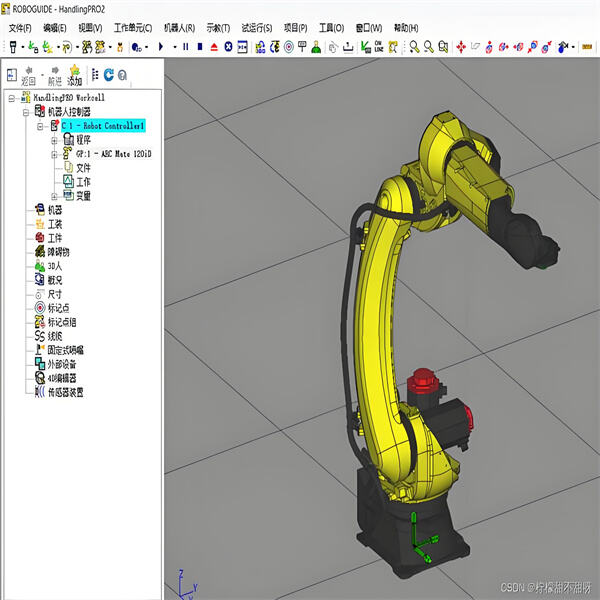

Გთავაზობთ ძალიან სიმძლავრი საკერძო რობოტის წინა ჩატვირთვა, გვერდიდან ჩატვირთვა, შებრუნებული ჩატვირთვა, განრიგი მაუნტინგი, ინტელექტუალური ტრაექტორიის გეგმა რამდენიმე რობოტისთვის, რამდენიმე გარე ღერძებისთვის და პოზიციონერისთვის საერთო მუშაობისთვის. რეალიზებს რობოტის მოძრაობის სიმულაციას, კოლიზიის გამოკვლევას, ერთობლივობის გარეშე და ღერძის ზღვარის გამოკვლევას.

Გამოყენებით ფუნქციების ძებნასა და გადამოძრაობას, სკანირება სველის კრავის, დადასტურებს კრავის ადგილმდებარეობასა და ინფორმაციას, განახლებს სველის ადგილმდებარეობას 3D ციფრული მოდელის და რეალური ნაწილის შორის, ამოხსნის პრობლემას სველის გადახრის გამო შესაბამისი მასალების შეცდომებისა და თერმული დეფორმაციის გამო.

Пекинს Minyue Техნოლოგია Co., LTD, როგორც მსოფლიო მიერ მובילი სამეცნიერო კომპანია ინდუსტრიული რობოტების გარემოში განათლების გარეშე ინტელექტუალური აპლიკაციები. ჩვენ განხილული ვართ წყვეტილი ინტელექტუალური შემუშავება ჩვენს თვით-განვითარებული RobotSmart - ინტელექტუალური გადაწყვეტილების სისტემა, SmartVision - ბინოკულარული სტრუქტურული სინათლე ვიზუალური სისტემა, და SmartEye - ლაზერული ვიზიუალური შემდეგი სისტემა. გთავაზობთ ახალი გენერაციის ინტელექტუალური რობოტული საკერძო და დაჭრივი ამოხსნები.