Hi folks! Today we will learn about robotic laser welding. Have you ever watched robots working? Maybe on the big screen or in the factories? Robotic Laser Welding: Just imagine robots speed up using special lasers to join metal parts. It is a fascinating tech that makes all sorts of things that we use every day.

When referring to robotic laser welding, it is like the superhero of the manufacturing segment. It is extremely precise so it produces strong and perfect welds. As a superman is fast and strong, a laser beam robot is fast and accurate. That is why they are very efficient! Where very strong metals, i. e. steel, and light metals like aluminum have to be joined, this technology can be applied. Because of this, this makes MINYUE laser welding robot system a very significant tool in the production of various products.

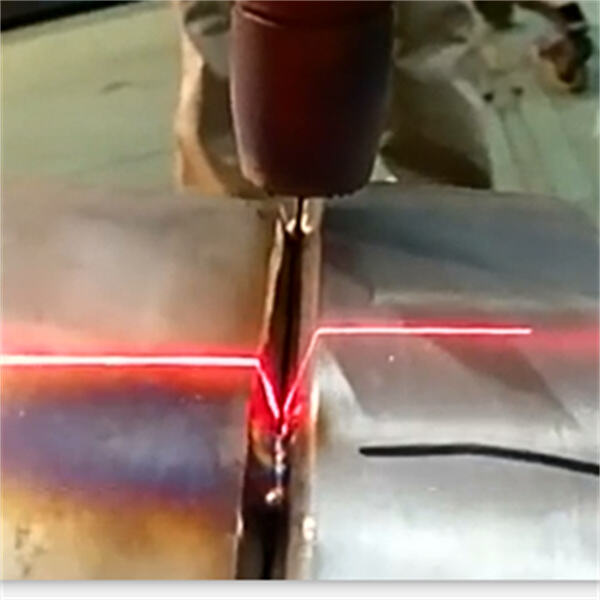

Essentially, robotic laser welding is the act of employing a robot arm and a high-intensity laser beam to fuse and join metal workpieces. The laser pulse is purportedly powerful enough to weld the metals independently, even without the inclusion of solder or other material. Solder is an alloy that's intended to assist in joining things together, but with robotic laser welding, solder is not only an unwanted ingredient, it can also be an unavoidable parasite. This is a positive aspect in that it forms a very clean and strong weld that will last present for longer. The robot glides the laser beam slowly across the edge of the metal pieces to weld them together as precisely as possible. Like a professional painter painting a straight line!

How Robotic Laser Welding Helps the Manufacturing Industry? A major benefit is that it's fast and accurate. Robots move faster than humans and can perform extremely accurate welds. This is great in general for businesses, as it saves time and money. Further, MINYUE robot laser welding machine gives very clean welds, so there's less extra work downstream to repair or clean them up. This results in higher quality products, and customers are pleased when receiving their items.

Robot laser welding is revolutionizing the manufacturing world on a large scale. MINYUE automated robotic welding speeds the production and makes it cheaper, something that’s useful for many companies. Companies can make more in less time with robots welding their products. This enables them to understand the demands of their customers better, and make sure that everyone gets exactly what they want. Also the quality of products are persisting and last longer due to strong and longer lasting welds made by robots. Strong products translate to customers being more likely to be pleased with what they purchase.

The smartest method to weld when it comes to automation is certainly robotic laser welding. Increasingly more utilizing robots in manufacturing because it is quick and very accurate. And when you add a high-powered laser beam to the mix, you have a great method to effectively weld metal parts together. This combination of robots and laser technology is revolutionizing manufacturing. These are just a few of the advanced technologies that are changing the future of manufacturing, and there are several more exciting developments in the pipeline.

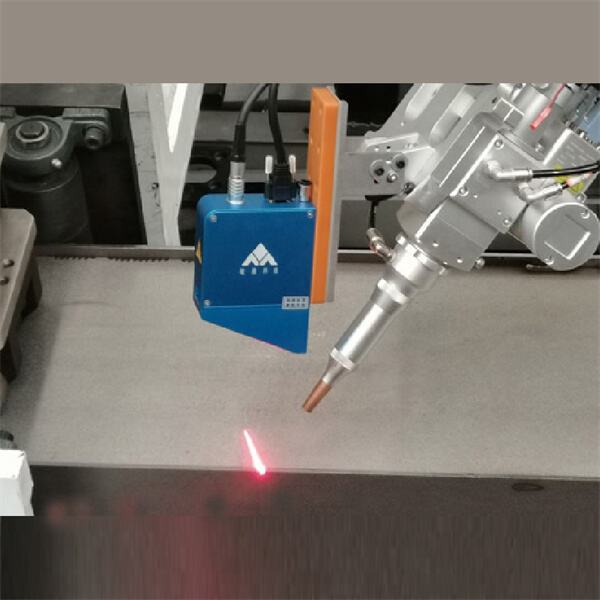

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.