- Prezentare generală

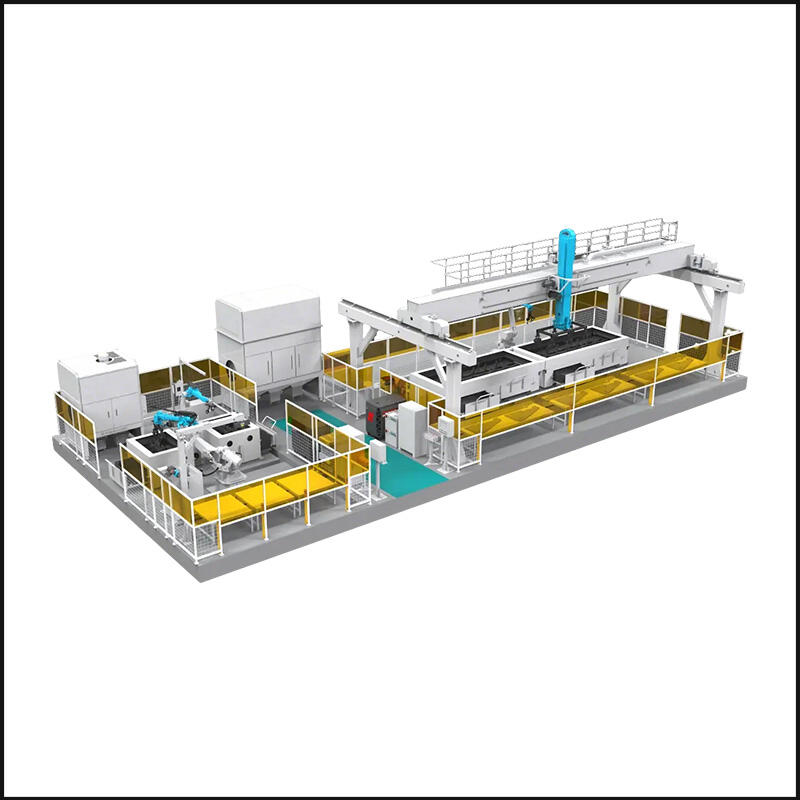

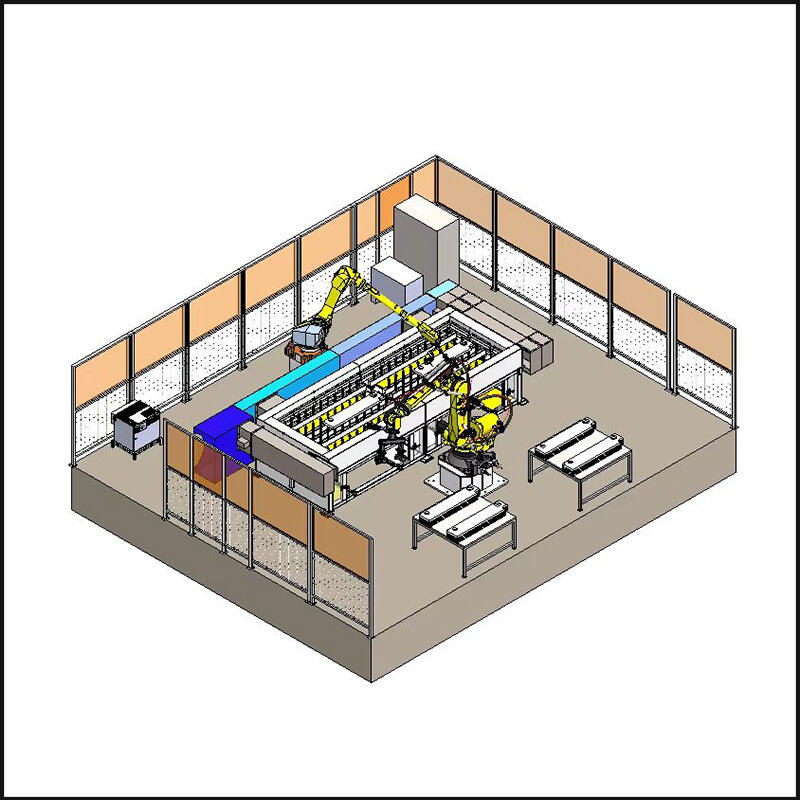

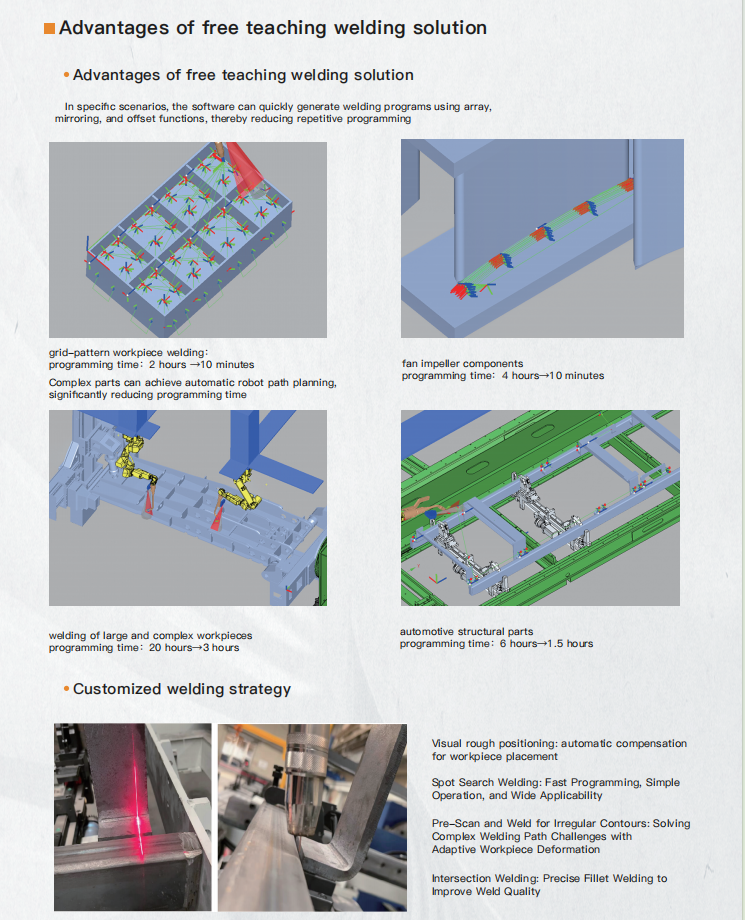

Sistemul de control inteligent de sudare fără învățare al tehnologiei MINYUE s-a angajat în domeniul automatisării robotice a sudării cu ani de experiență. Pentru rezolvarea punctului dureros din industrie. De exemplu, scăderea continuă a numărului de sudori, precizia insuficientă a descărcării și a montajului pieselor, o cantitate mare de lucrări nestandard și mici necesare în construcția metalică, construcția navală, industria grea, fabricația etc. Acesta oferă soluția inteligentă de sudare caracterizată prin avantajele integralei complete și lipsa de învățare.

Sistem de sudare fără învățământ

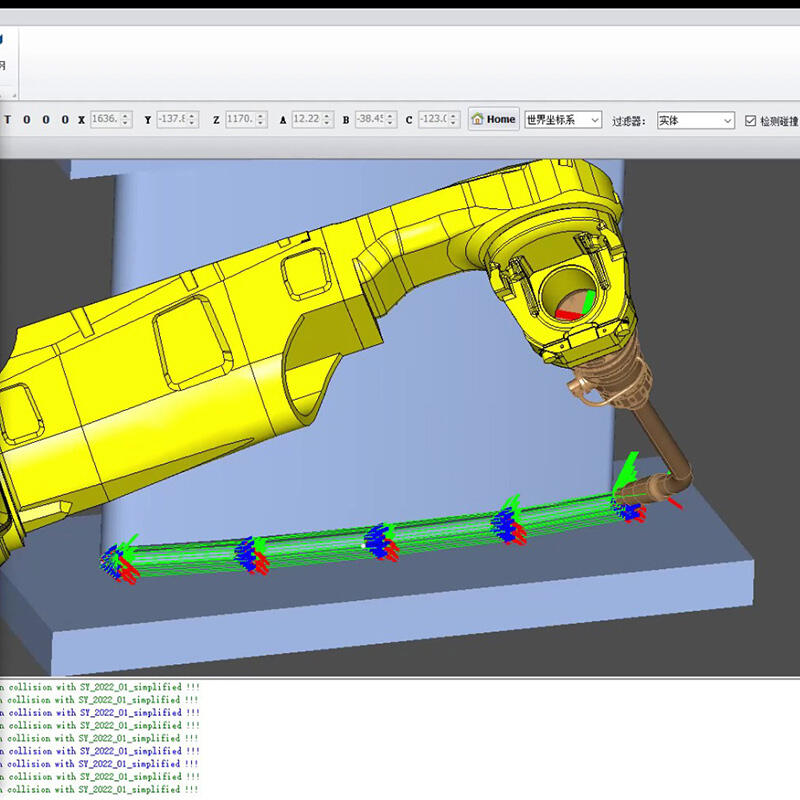

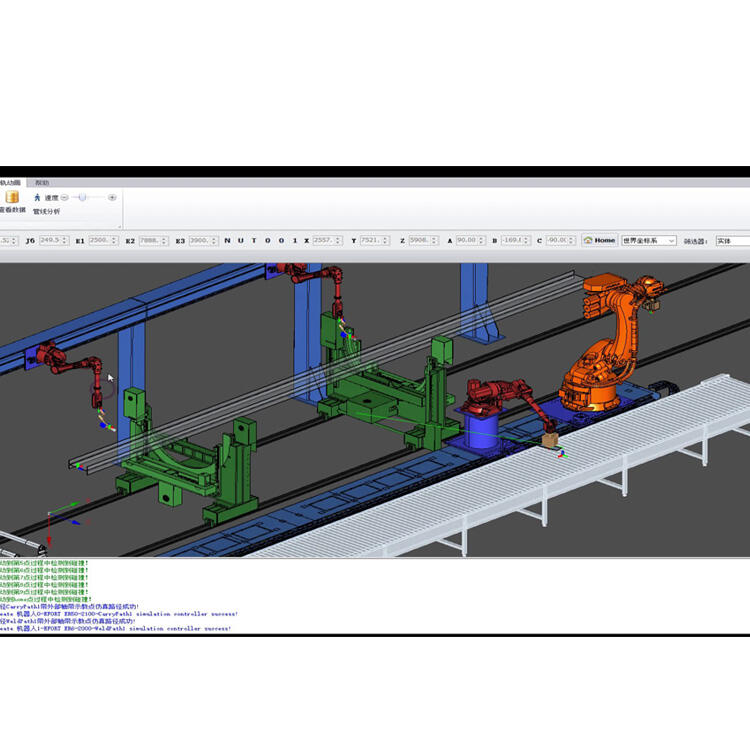

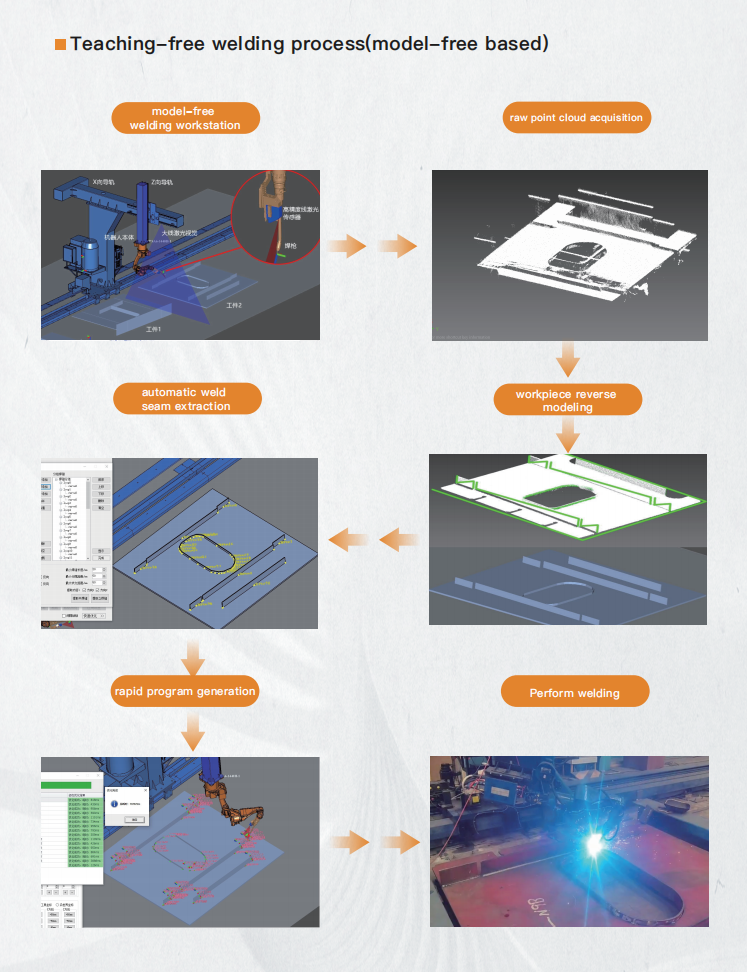

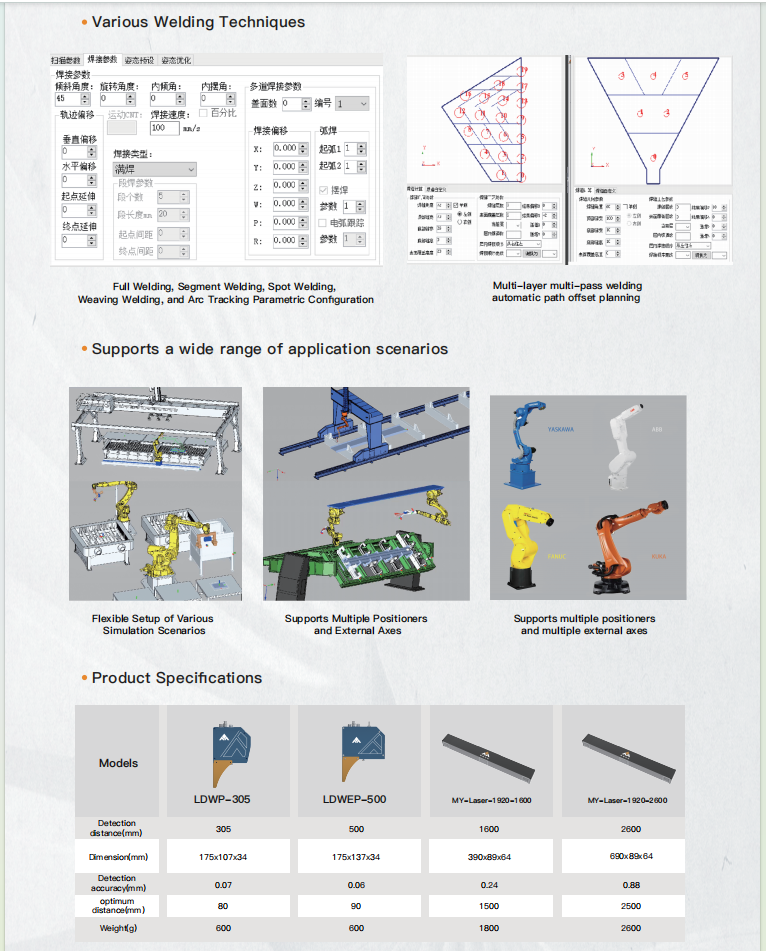

Sistemul de sudare fără predare susține principalele mărci de roboți, inclusiv KUKA, FANUC, ABB și Yaskawa, precum și mărcile locale cum ar fi Siasun, Estun și Efort. Prin integrarea sistemului de vizion laser autodezvoltat SmartEye, sistemul de sudare și tăiere fără predare constă într-un sistem de decizie inteligent (RobotSmart), un sistem de urmărire prin vizion laser (SmartEye) și un sistem de modelare prin vizion cu vedere largă (SmartVision). Prin colaborarea dintre cele trei sisteme, prin importarea schițelor 3D în sistemul de programare offline RobotSmart, se generează traiectorii de sudare a robotului (inclusiv puncte de scaneare, puncte de sudare, instrucțiuni de sudare, etc.). Modelarea inversă a pieselor de lucru cu camera de scaneare pe linie cu vedere largă a sistemului SmartVision. Poziționarea precisă a joieturilor de sudare prin senzorul de vizion laser al sistemului SmartEye. Realizează sudarea automată fără predare a piesei de lucru curente.

Ajută fabricanții să depășească provocările legate de o complexitate ridicată a programării și de niveluri scăzute de automatizare, îndeplinind în același timp cerințele de producție a sudurilor pentru loturi mici și diferite tipuri de piese, ceea ce contribuie la îmbunătățirea eficienței de procesare și a rendementului produselor.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK