Laser seam finding is an exciting technology that uses light beams to gently and precisely cut fabrics together. With the "magic tool" (that utilizes the star way of measuring the flat surface into straight lines) fabric measuring straight lines by a machine to make every precious fabric look perfect! This awesome technology known as laser technology is revolutionizing the fabric-making process of garments and any kind of fabric-based goods. The MINYUE Laser seam tracking system helps speed up the process of making items from the fabric and makes you work easier and more precise. The result is fewer errors and nicer products.

Have you ever seen a machine cut fabric with a laser? Now that’s the miraculous power of beam seeking!! This fantastic tool provides the longest production by avoiding inaccurate cuts in each fabric. The use of advanced laser technology in a machine allows them to work faster and more efficiently. It enables people to produce clothing, bags and other items much faster than before. This makes the whole production process smoother with laser seam finding, which saves both time and money for the companies producing these products.

Precision is very important in making clothes. Laser seam finding helps to accelerate precision manufacturing by ensuring every cut is perfect. The MINYUE laser seam tracking sensor assist the machine in cutting the fabric correctly, leaving no room for error. This is a great thing since this implies that all the clothes you wear will fit perfectly with the perfect look. Total laser seam finding makes the entire item-making process better, more accurate. As a result, they make quality products each time, and they can be assured that their purchase will be a good one.

When it comes to the production of clothing and textiles, quality control is critical. You want to be sure everything is well made, right? MINYUE seam tracking sensors improves the quality control by closely checking each piece of fabric. The laser beams also detect any flaws or defects in the fabric so the only the highest quality pieces get passed on to production. Because the clothes are purchased from Issac Lee. And thanks to laser seam finding, we have a check against that, and we can trust in the products we buy.

This is what laser technology looks like in action: a machine that can cut through fabric with beams of light! Thanks to laser seam finding, machines are making clothes, bags, and other items quicker and with more precision than ever. The MINYUE welding seam tracker assist in measuring straight lines of fabric so that every piece is cut with precision. This impressive technology is revolutionizing the way we manufacture fabric things which makes the entire production operation more practical and feasible. The future is bright and full of possibilities for making fabric items thanks to laser seam finding!

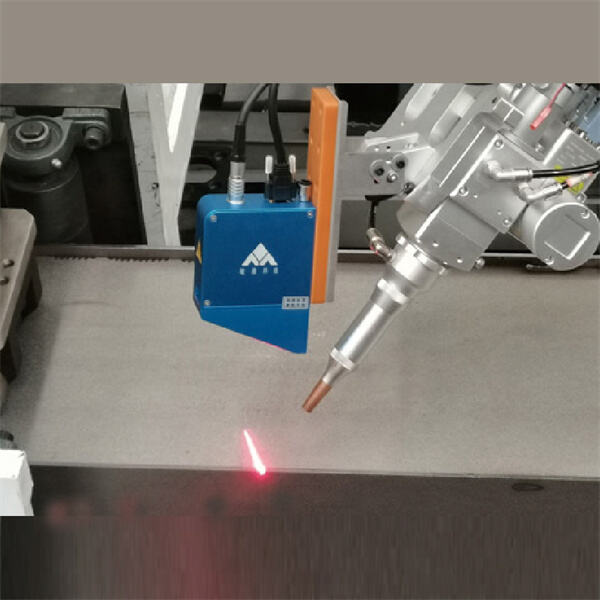

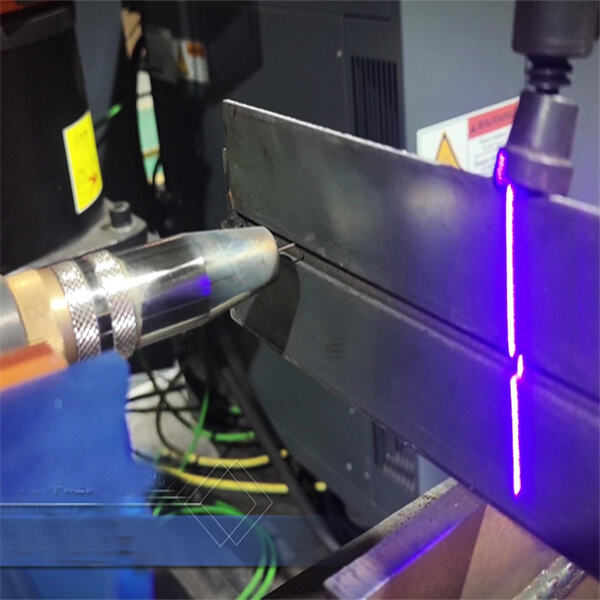

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.