The world is moving so fast today that technology is becoming more and more advanced. Invention is something that brings an extreme difference in many fields, and one such invention is the 3D laser vision sensor. This incredible tool is revolutionizing processes and streamlining work across sectors. Let us explore the capabilities and benefits of 3D laser vision sensors.

A MINYUE 3D laser vision sensor as well as binocular structured light vision sensors is a specialized device that utilizes lasers to generate a three-dimensional representation of it is surroundings. This means it is able to measure how far objects are, their shape, and their dimensions to a very high degree of accuracy. You are like a superhero because you can see things in 3D. That’s what such a 3D laser vision sensor can do.

From Manufacturing to healthcare, 3D laser vision sensors as well as laser vision sensor are assisting a wide range of organizations. These sensors are used in manufacturing where they can help with the quality of products by locating errors very accurately. They also appear in self-driving cars, where they help the vehicles navigate safely through complex environments. Aerospace and defense, automotive, electronics, and healthcare are some sectors where this device is utilized. In the healthcare sector, 3D laser vision sensors are used in machines that capture images of patients' bodies, enabling doctors to better visualize the problem and to provide effective treatment for diseases.

The uses for 3D laser vision sensors also the 3d machine vision camera are limitless. And, as the technology grows, these sensors are getting stronger, more precise and capable of more functions. They are being incorporated into drones for improved flying and obstacle avoidance capabilities. In agriculture, 3D laser vision sensors are used for measuring the health of crops and make the farming smarter. We can only speculate on how sensors will continue to innovate our future.

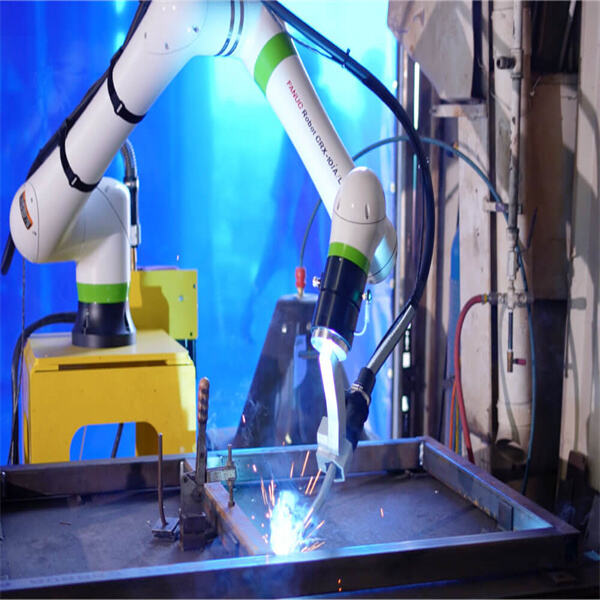

Using MINYUE 3D laser vision sensors is one of the coolest known applications of robots, along with binocular structured light vision sensors. These sensors enable robots to observe and interact with their environment. 3D Laser Vision Sensors which enable robots to locate and manipulate objects, traverse harsh environments and perform highly precise tasks. This allows robots to be more autonomous and intelligent, thus presenting numerous opportunities for automation across various segments.

As technology continues to develop, the MINYUE 3D laser vision sensor and areas of the technology are also expanding. This motivates scientists and engineers to continually improve and enhance both the robustness and functionality of these sensors. New technology allows them to scan quicker, provide sharper images and be more precise. This technology is enabling companies to operate more efficiently and become more productive.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

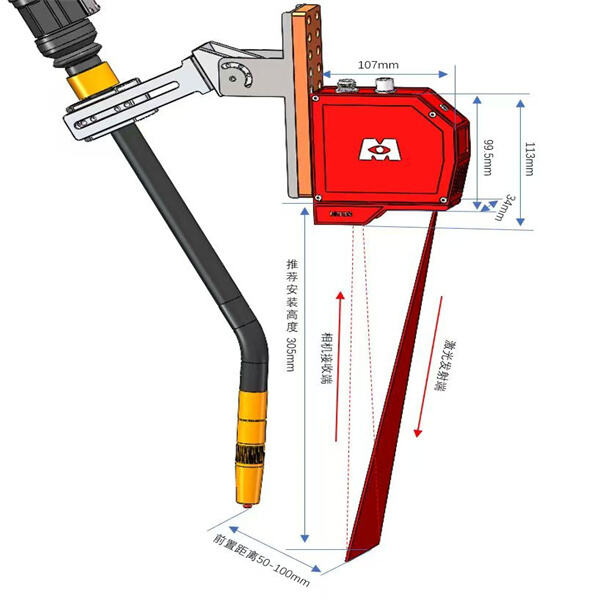

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.