Hello! Do you even know what a laser vision sensor is? It may sound like something from a science fiction movie, but it is real technology that aids machines and robots. We are going to discover today what are laser vision sensors, and how they are impacting the way we see about machines and robots in our daily lives. Laser vision sensors are tiny devices that use lasers to "see" its viscinity. Similar to how our eyes enable us to see where we are headed and what is in our vicinity, laser vision sensors allow machines and robots to perceive their environment. These distance measuring sensors fire lasers around themselves, creating sharp, detailed images of objects and environments. This enables machines to make quick and accurate decisions. The Laser Vision Sensor: For example, a robot may use this vision sensor to make sure it is correctly aligned with a specific object it is trying to pick up. This is critical for robots that operate in factories or on assembly lines.

Machine vision is a specialized kind of technology that enables machines to see and comprehend the world around them — similar to the human way. Laser vision sensors are a game-changer in the field of machine vision that are capable of providing image data signals with extreme precision and detail that are unattainable by conventional methods. This means workpieces that are unseen, such as scratches or changes in color, can be detected with laser technology and then, assistants make decisions according to the images produced by the camera as well. This can be particularly useful in industries such as manufacturing and robotics where accuracy is crucial. That is, you don't just want a laser beam sensor machine to detect a small flaw in a product; you want it to alert workers to fix it immediately, so that no products get out that aren't of the best quality

Product Manufacturing: Quality control is a very important part of product manufacturing. The organizations are required to ensure their products go through quality checks before selling to customers. Laser vision sensors help makequality control more accessible, more reliable than ever. While they are scanning the product with lasers to search for any defects or flaws, companies can catch issues before they ever leave their doors. So, only the winning products reach the shelves to be purchased by customers. For instance, if a toy has a tiny flaw, the laser proximity sensor will be able to detect it quickly, so the company can ensure that the toy is safe and fun for children.

Automation is a fancy term that describes the use of long range distance sensor machines and robotics to take over tasks that people generally perform. June 12, 2021 — Laser vision sensors make machines smarter and more capable. You give machines the gift of "sight" and the ability to think independently, how exciting! This enables businesses to automate more tasks than ever, enhancing efficiency and productivity. Visualize an industrial factory in which unassisted robots may co-work with each other without regular human support. They can do the job more quickly and with fewer errors, allowing the company to make more things in a shorter span of time.

Vision laser sensors are changing yet another fast-growing field: Robots are employed in a wide range of fields including manufacturing, healthcare, and agriculture. Companies can use laser vision sensors to help robotic systems operate safely and efficiently. high speed laser sensor can be used in various applications, such as inventory management, construction, and manufacturing. This is critical in environments such as hospitals, where such robots must be able to navigate pathways to deliver supplies without crashing into people and other apparatus.

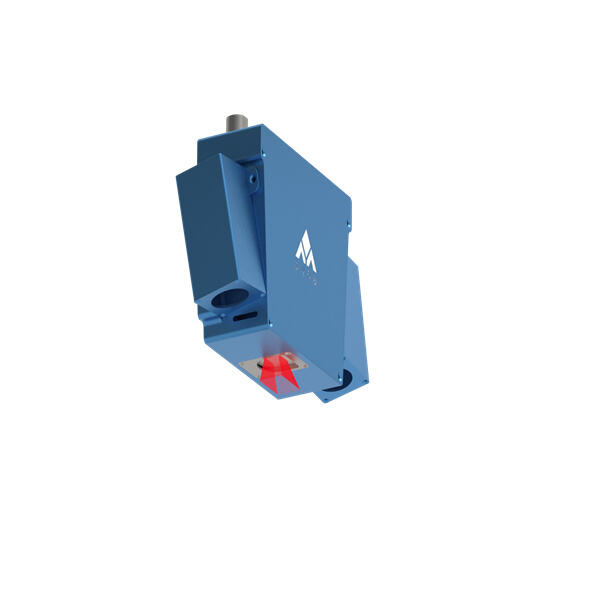

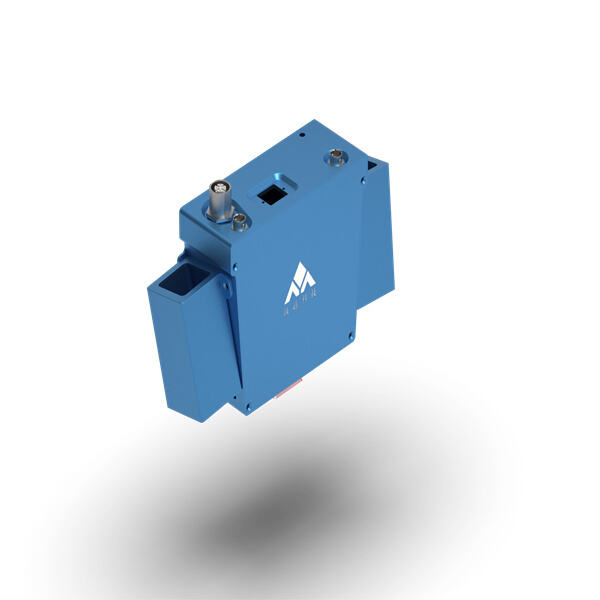

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.