The machine vision camera is an object which is able to see through 3D point of view just as human see. That is, it is able to sense the shape and depth of its surroundings. These are very powerful cameras that are revolutionizing the production process. So bear with us and let us get in deeper into just how marvelous these cameras are!

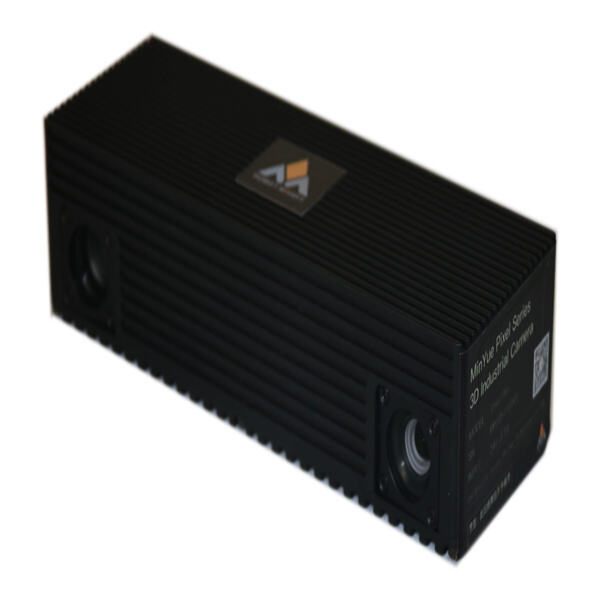

3D machine vision cameras are sophisticated sensors employed for detailed three-dimensional evaluations to better comprehend the image data they gather. This ability allows factories to manufacture products more quickly and of better quality. It's important that cameras are able to check whether everything is being produced properly. They detect even small mistakes humans cannot see, imagine producing toys or devices, if a small thing gone astray, it will be problematic. This is made a lot easier with this MINYUE 3d vision camera, saving enormous amounts of money and time in the production of things.

Vegetable suppliers also benefit from receiving 3D machine vision cameras for accurate packaging. This kind of cameras can measure things with high precision. If a toy needs to be a specific size, the camera will ensure that the every single toy coming from the factory is perfect. Which translates to fewer mistakes and fewer need to throw away products. This is not only benefiting the factories but is also good for the environment because less waste is being produced. Utilizing these cameras allows factories to create more products in a shorter period time, great for business and keeping costs low for everyone.

These 3D machine vision cameras can measure things very accurately, which is one of the coolest things about them. This is important for creating products that need to be a certain size or shape, especially. If a car part must fit perfectly, for example, the camera can verify that it is the correct shape and size before being placed in a car. This is to ensure everything functions properly and helps keep us safe while we drive. The MINYUE binocular vision camera can quickly check many parts straight away, making the whole process a lot more efficient and reliable.

You might expect that 3D machine vision cameras are only used inside of factories, but in fact there are many different ways that 3D machine vision cameras can be used. For instance, they can also assist physicians in operating rooms in hospitals, where they can provide detailed images of the site of work. This improves surgical safety and precision. In shops, these cameras help keep up with the number of things in stock, which means they can see how many products are in stock. This allows stores to know when to restock. These cameras can even be in our homes and can help with security and keeping our families safe or they can help with cleaning and make cleaning easier. These incredible cameras can be used with endless possibilities, and as technology develops further we are bound to discover even more fun methods of utilizing them.

MINYUE 3D machine vision cameras utilize specialized sensors and sophisticated software called algorithms to take a highly descriptive 3D image of its target. These cameras are able to make thousands of measurements per second in order to construct an accurate image of what they are seeing. This information is transmitted on to a computer, which analyzes it and instructs the camera as to what it should do next. Basically, it's one very clever robot that can see and knows about its surroundings. This kind of technology allows the cameras to aid with a whole range of tasks, such as making them more convenient or simpler.

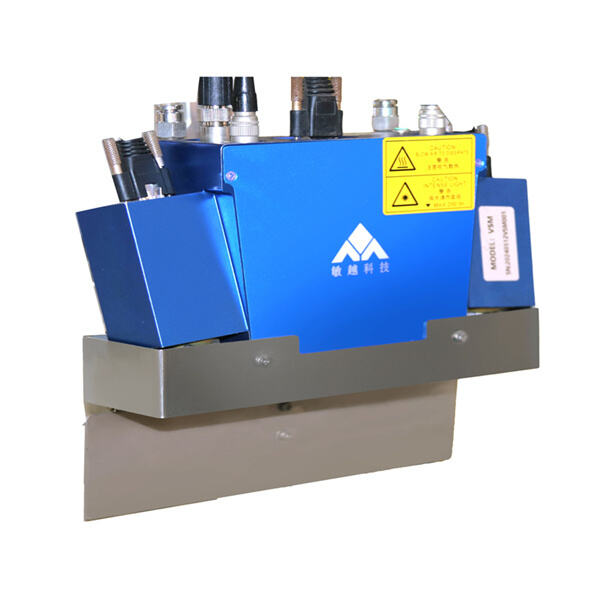

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.