There are many tools used in robotic welding and seam tracking sensors are one of the most important. These MINYUE laser seam tracking sensor enable the robots to follow the seam, the joint between two pieces of metal. If you follow this seam correctly, you will get a much better weld or joint where the pieces of metal are joined together. Seam tracking sensors are useful for robots as these sensors allow the robot to weld more accurately and efficiently, and are often used in many industries.

Seam tracking sensors are important for a number of key reasons, one being that these sensors keep the robot on track during the welding process. If a robot is working with a piece of metal, it is very important that robot follow the seam exactly. If the robot is misaligned, it can produce either a week weld or no holding weld at all. Seam tracking sensors contain specialized technology that detects seam well, and directs the welding to the correct local. Maintaining a smooth, successful welding process.

While aiding robots to follow the track properly, seam tracking sensors also allow for accurate welding. They do this by rotating the welding torch, which is the tool melting the metal to keep the pieces held together, while the robot functions. So, even if the metal pieces are not perfectly straight, or have a lot of bumps, the sensors can pick up that variation. When things appear to go wrong, the sensors can immediately modify the torching weld. This results in a more accurate and consistent weld, critical to many operations, particularly those with heavy-duty, reliable joints.

Also, seam tracking sensors make the welding process quicker and more efficient. While robots can work more efficiently by automating the process of following the seam. Volume work is especially important for any kind of industry where many metal pieces must be welded together within a short amount of time, such as factories manufacturing cars or airplanes. Seam tracking sensors assist robots in doing their jobs in less time, enabling companies to achieve their production targets.

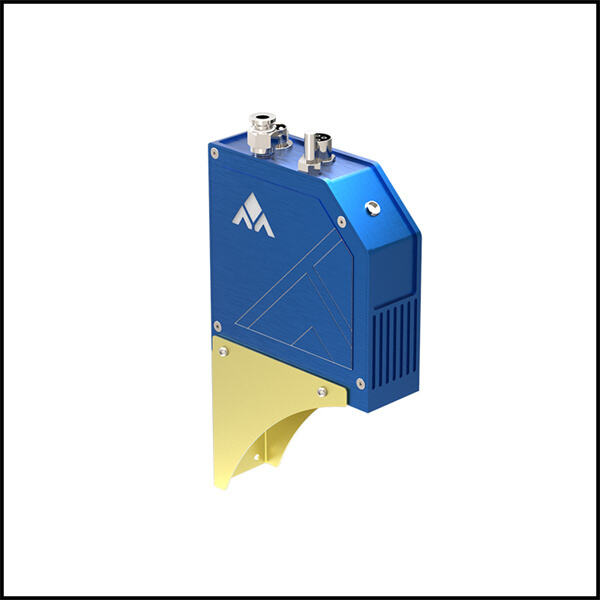

Seam tracking sensors advances in technology have given them improved usability over their predecessors. Newer sensors are capable of identifying seams faster. They are also capable of functioning in various environments, meaning they can be used in conditions with low levels of light, or on bright surfaces that can be tricky to see. MINYUE welding seam tracker versatility makes them ideal for a variety of welding jobs.

Seam tracking sensors are widely used in the industry since they offer many advantages. MINYUE binocular structured light vision sensors enhance quality and speeds for welding, as well as minimize errors and reduce rework. This is critical because correcting errors can be time-consuming and expensive. In turn, the companies relying on robotic welding can cut both time and cost, making them more efficient in their operations with the adoption of seam tracking sensors.

Consider your industry's needs when selecting the right seam tracking sensor types for your welding application. When it comes to different types of metal or even different types of welding processes, MINYUE different types of sensors in robotics may work better than others. For instance, whilst some sensors are ideal for thinner metals, others might be able to penetrate thick metals. MINYUE specializes in delivering exceptional seam tracking sensors, providing a full range of high-performance solutions to cater to the unique needs of their clients. By offering a multitude of options, businesses will be able to find the ideal sensor for their particular welding application.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.