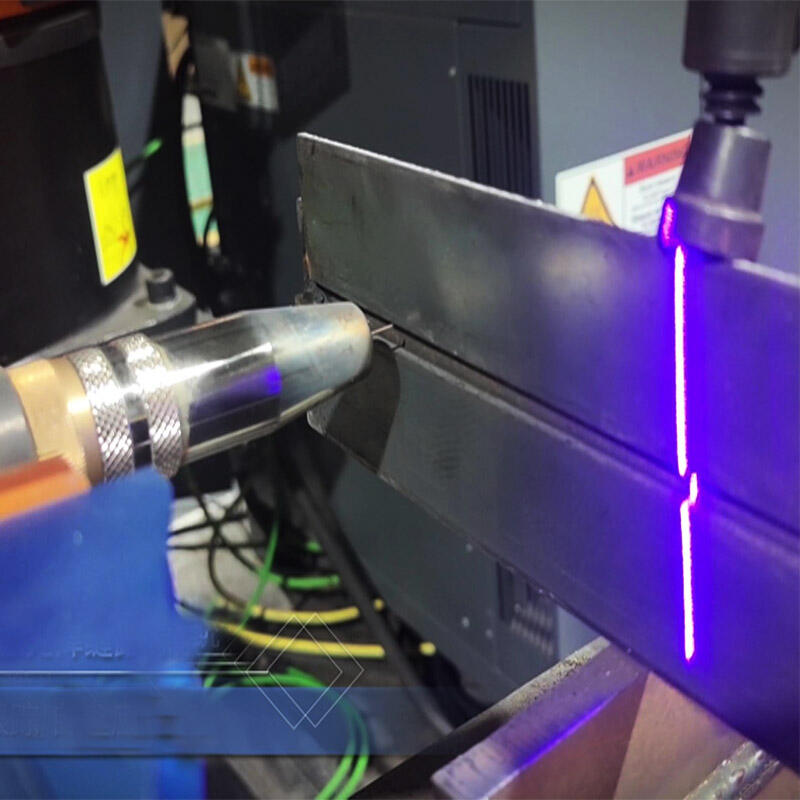

A localización por laser e o seguimento por laser son o ensino manual da pista de soldadura a través da identificación por laser, equivalente a dar ao robot un par de "ollos".

No proceso de ensino manual, as uniones de soldadura están susceptibles de deformarse, ter variacións na separación e erros de montaxe, o que provoca grandes desvios nas uniones durante o proceso de soldadura. Para mellorar a calidade da soldadura, é necesario un control en tempo real dos robots de soldar para corrixir os desvios das uniones.

Hai tres formas principais de atopar a posición da costura: tacteo, indución por liña e indución láser:

Tacteo: Detectando a costura coa superficie da peza tocándoa fisicamente con unha liña ou bico, este método é simple pero lento.

Indución por liña: Emprega un motor de servomecanismo para mover rapidamente a liña arriba e abaixo mentres o robot se despraza ao longo da peza. Detecta costuras chanfradas que son difíciles de atopar con un tacteo estático de liña ou bico, pero require hardware e software específicos.

Sensado por laser: Máis rápido que o sensado táctil, pode detectar un espesor de 1/16 de polegada na unión, pero ten limitacións na detección da separación da unión, non podendo atopar unhas uniones de chanfle rectas.

Minyue Technology apoýase no equipo de Tsinghua University e no equipo da Universidade de Aeronáutica e Astronáutica de Beijing, baseándose en robótica, visión 3D e algoritmos de intelixencia artificial de vanguardia combinados con problemas prácticos, lanzou funcións de corrección de posicionamento como o posicionamento de dous puntos, tres puntos, segmento de liña e outras.

Función unha: busca de dous puntos

A posicionamento de dous puntos basea-se no desenvolvemento da función de posicionamento dun punto, pode determinar a trayectoria e a dirección do sopeiro a través de dous puntos dun sopeiro, de modo que, mesmo que a nosa peza teña erros de desprazamento e rotación, o posicionamento de dous puntos tamén pode resolver os seus problemas de soldadura. Adequado para soldaduras intermitentes curtas na industria, erro de rotación da soldadura.

Función dous: busca de tres puntos

O principio do posicionamento de tres puntos é estabelecer un novo sistema de coordenadas baseado na peza, para axustar ao sistema de coordenadas orixinal, calcular a posición e o desprazamento de cada sopeiro, e relocalizar as pezas complexas de estructura, o que é adecuado cando a nosa consistencia das pezas é boa, pero hai erros de colocación e prensa.

Función tres, busca de segmentos de liña

Localización de segmentos de liña, toma catro puntos no peza, toma dous puntos en calquera bordo, forma tres segmentos de liña, obtén coordenadas de usuario tridimensionais a través dun cálculo, para asinalar co sistema de coordenadas orixinal, calcula a posición e o desprazamento tridimensionais de cada soldadura.

Se hai un gran número de pezas iguais, é necesario un posicionamento ou seguimento láser para determinar a trayectoria, e certamente ocorrerán erros nun gran número de pezas, sendo necesario o láser para compensar o erro, podendo controlarse a taxa de cualificación da soldadura en máis do 90%.