Laser line scanners are pretty neat devices that utilize lasers to shoot out detailed pictures of various types of objects. They emit a laser beam that sweeps back and forth across an object and perceives its shape and features very accurately. Such scanners are used in different sectors to get accurate and useful information for several purposes. This is to make sure they assist people in understanding and studying the objects better!

The way we collect data has completely shifted with laser line scanner technology. Previously, people had to calculate distances manually, which was not only labor-intensive but also, in many cases, not uniform. For instance, imagine someone measuring the length of a table. One can make a mistake with the tape measure. But MINYUE laser line scanners can gather data much more rapidly and with great accuracy. This technology serves to simplify and speed up jobs such as quality control and product verification. This enables workers to spend less time measuring, and more time on the meaningful work at hand.

Laser line scanners find application across several industries save CAD/CAM, building design, and biotechnology. In manufacturing, these scanners ensure that quality measures are met. This is really important, ensuring customers get the best product. Architects employ laser line scanners to model buildings in three dimensions in detail. This allows them to see how a building will look before it's built. Laser line scanners used in Healthcare: MINYUE Laser line scanners help in taking accurate measurements while preparing for several surgeries, allowing specialized doctors to perform niche work with utmost precision. Laser line scanners can be used for endless applications!

As such, one of the main advantages that laser line scanners offer is a highly accurate measurement capability. This is vital in sectors where precision is critical, such as in aerospace and automotive production. For example, when creating airplanes, all of the small measurements have to be on point in order to keep everybody safe. This MINYUE 3d vision camera provides distance, angle, and shape measurements with amazing accuracy and is one of the most useful tools many workers have. This precision allows workers to have faith in the measurements they receive, and perform their jobs more efficiently.

Laser line scanners can also be utilized in creating 3D images. These scanners create detailed 3D models that are useful in a wide variety of applications by scanning an object from multiple angles. This has transformed areas such as archaeology, where it can create virtual replicas of physical remnants, for example. Using laser line scanners, archaeologist are able to analyze items without having to touch them, not only preserving history but also learning more about it.

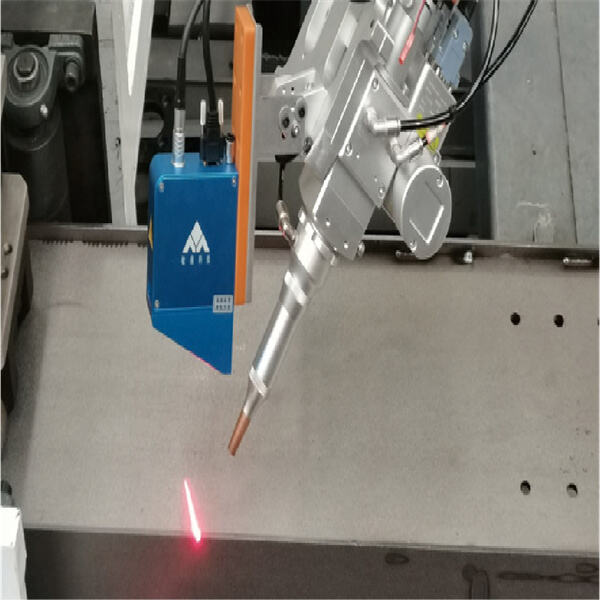

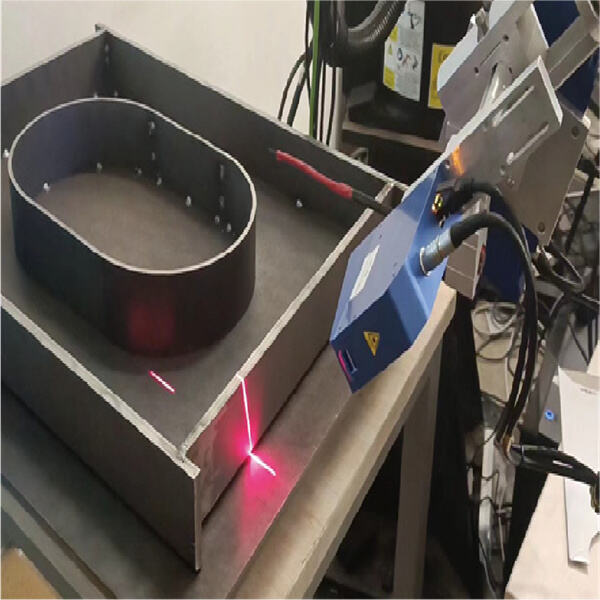

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.