Did you want to know: How can machines see in 3D? This is where 2D laser tracker profile scanner such as the ones produced by MINYUE come into play! Instead, they are special machines that use lasers to take pictures and get images of the things. This ensures that companies are creating better products which leads to customer satisfaction and ensures they are satisfied with what they are purchasing

Suppose there is a superhero having x-ray vision. This superhero has x-ray vision and knows what is on the other side. So, 2D laser profile scanners are a bit like that superhero! But instead of superpowers, they use lasers. These scanners beam lasers at something and measure how long it takes the laser to bounce back. This all is useful data since it creates a very detailed 3D picture of the object. Isn’t that amazing? It’s sort of like giving machines a way to “see” that makes sense to us about the world.

Previously, you needed humans to inspect whether products were manufactured properly. Pen and ink errors are often mistakes by tired or distracted people. This is where the 2D laser beam detector profile scanners come into play! These scanners run continuously without pausing, checking products for faults. They make sure everything is perfect before the products are sent off to customers. This not only saves companies time and money, but also ensures that customers get the best quality products. When products are made well, everyone benefits!

For companies, quality control is essential. They always wanted their products to be perfect before sending them out to the world. 2D laser beam sensor profile scanners streamline this quality control process significantly! These scanning systems are able to identify mistakes or imperfections in products accurately and rapidly. This allows companies to detect early any issue. By fast tracking the search and presence of critical issues early during development and delivery of a system, encourage a culture of less mistakes and iteration to deliver happier customers and better company standing. Satisfied customers are more likely to return and spend again!

Factories tend to be very busy places. It's all very frenetic, with machines whirring everywhere, people darting back and forth, and dozens of products all being produced simultaneously. In such a busy space, it is not hard for errors to pass unnoticed. This is the reason why tons of companies decide to use 2D laser profile scanners in their production lines. Then these scanners can collaborate with machines and workers to confirm in real time that everything is prime. Their collaboration allows companies to optimize their process and guarantee that each product passes the tranquillity of playing at home test. When all this works seamlessly, it enables the business to function more productively.

Not only are 2D laser profile scanners applied in factories. These have a variety of applications in different industries. For instance, these scanners track items from the warehouse to identify the inventory level. For example, they can take measurements for buildings in construction to ensure everything gets built correctly. In fact, they even have applications in human medicine, where they are used to take detailed pictures of the human body so that doctors can obtain more information to help patients. There are so many ways to use these scanners! As their technology advances, companies can leverage it to enhance their processes and sell better products for all.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

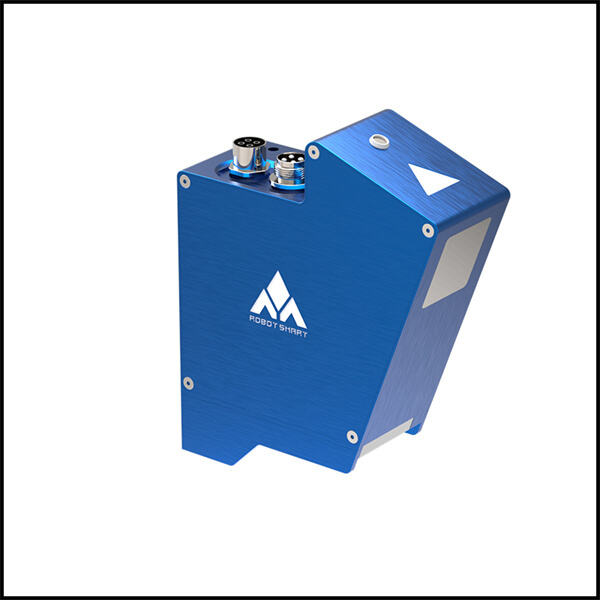

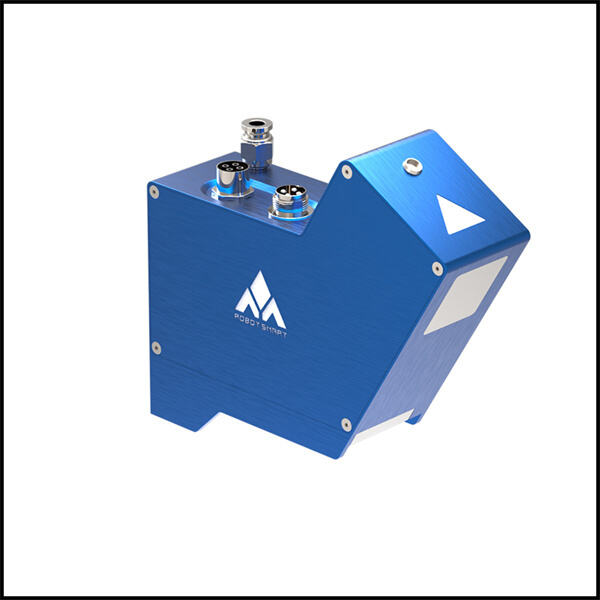

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.