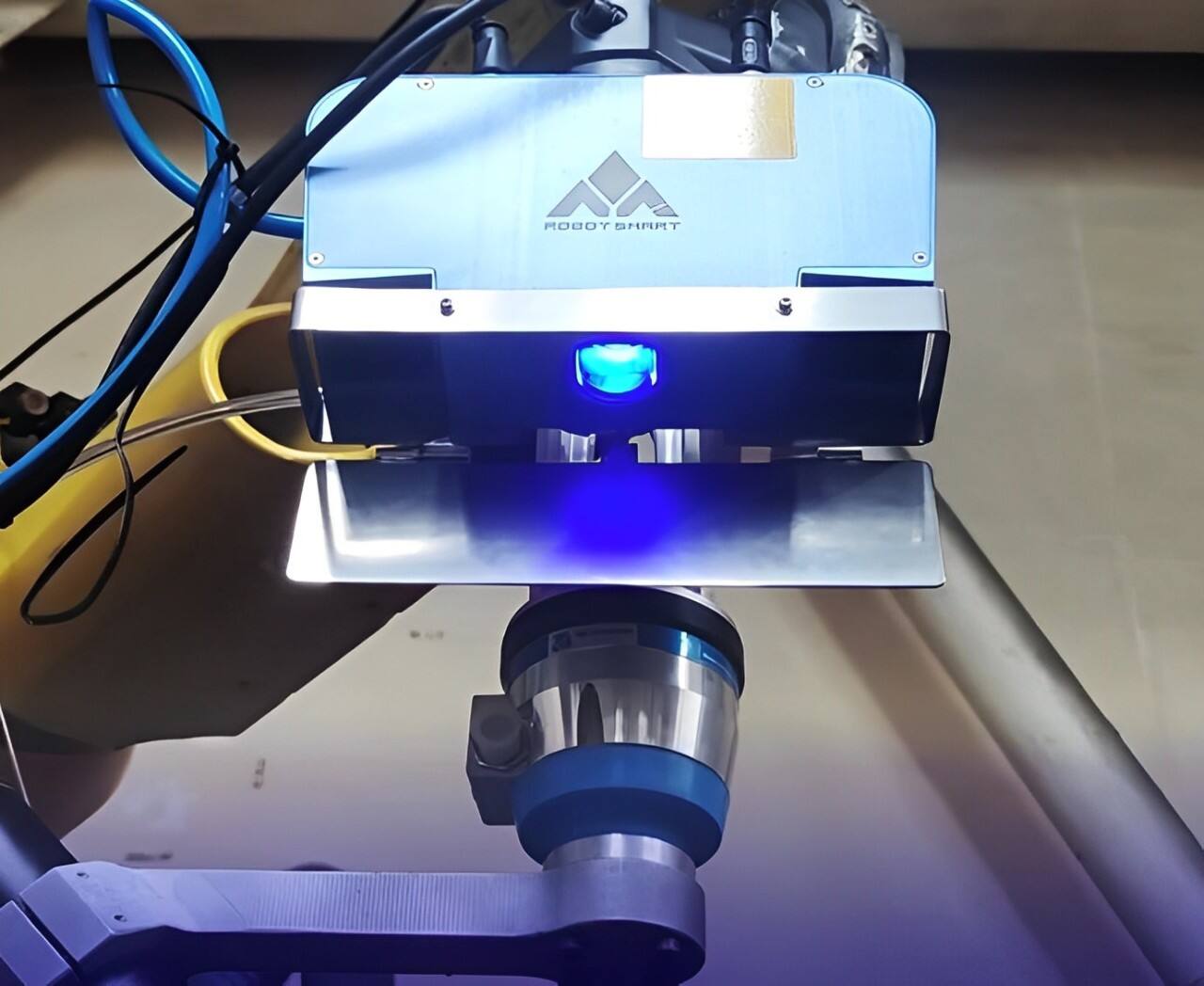

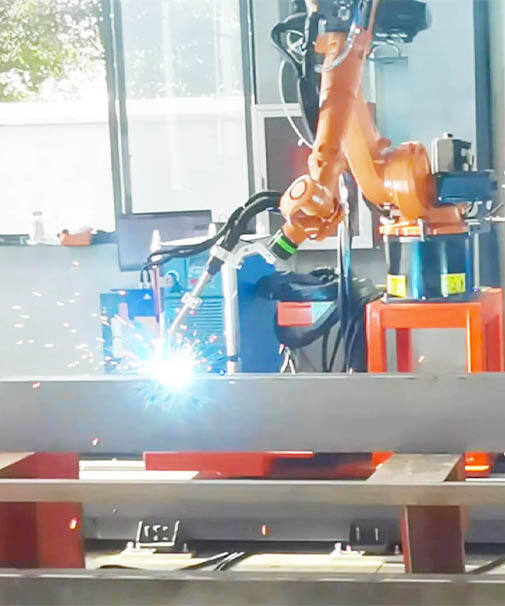

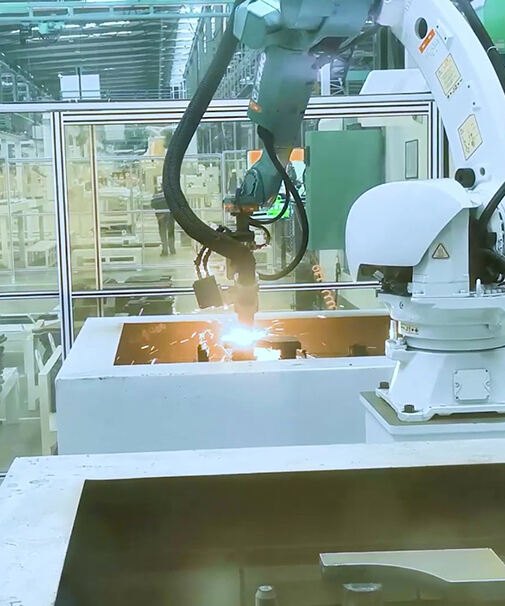

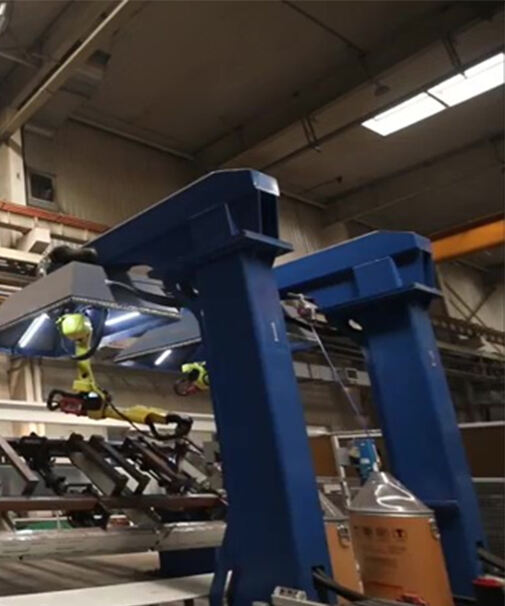

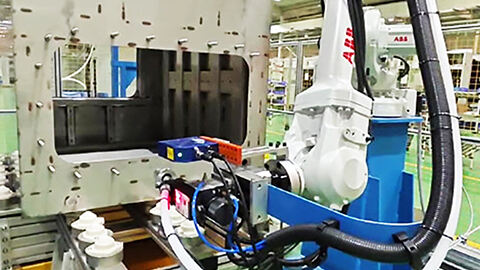

We are an construction machinery manufacturing company, in the traditional processing methods, manual operation is highly dependent on experience, low beveling efficiency, processing accuracy is poor, accompanied by noise, dust and other environmental issues, obviously can not meet the modern manufacturing industry on the efficiency and environmental protection requirements. Min Yue technology with “non teaching” technology, completely help customers get rid of these industry pain points, the first in the construction machinery industry to promote the application, so that intelligent cutting from ideal to reality.