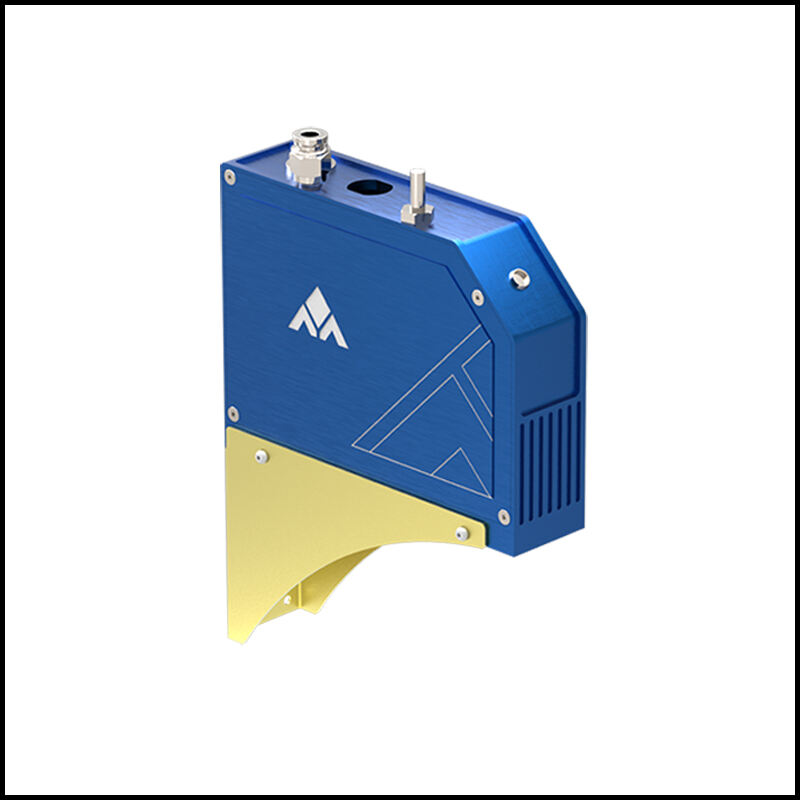

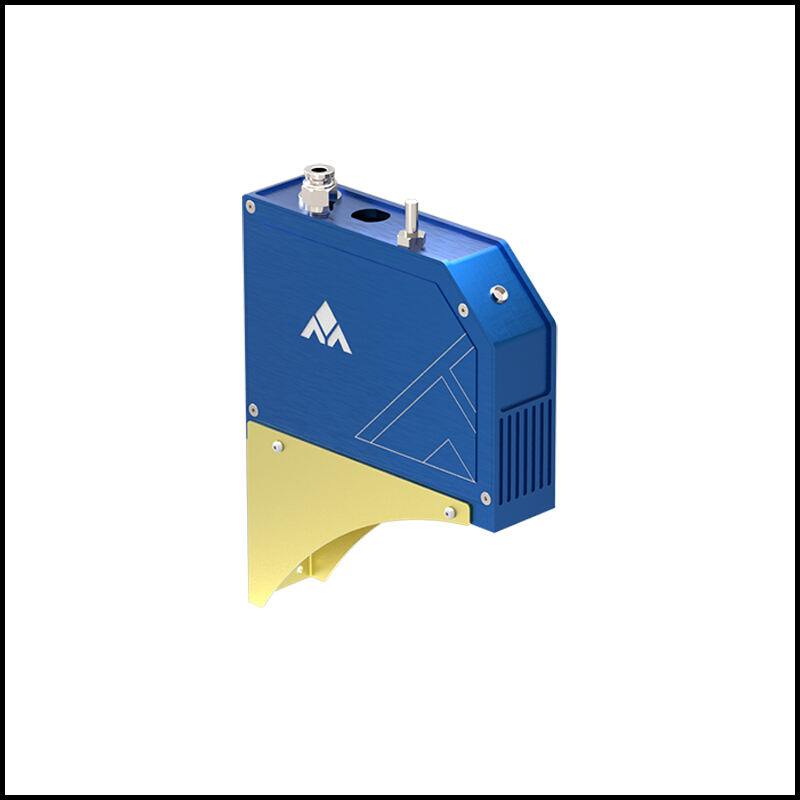

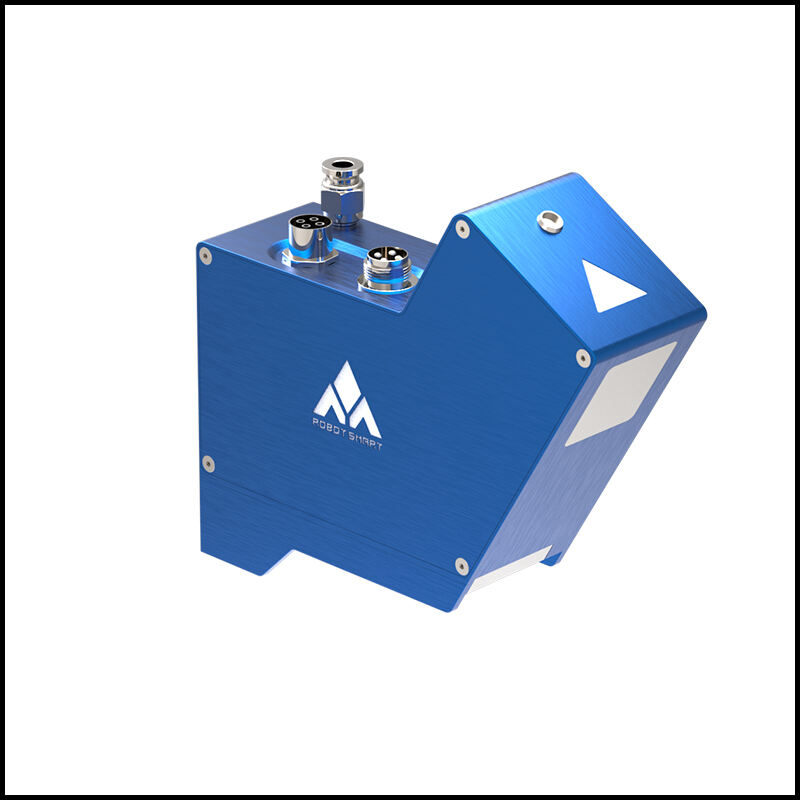

LDWP-305 Cảm biến theo dõi đường hàn Laser

Với chức năng 01. hiệu chỉnh vị trí và độ lệch, 02 Theo dõi thời gian thực, 03. Quét và hàn tự động.

- Tổng quan

- Hỗ trợ thương hiệu robot

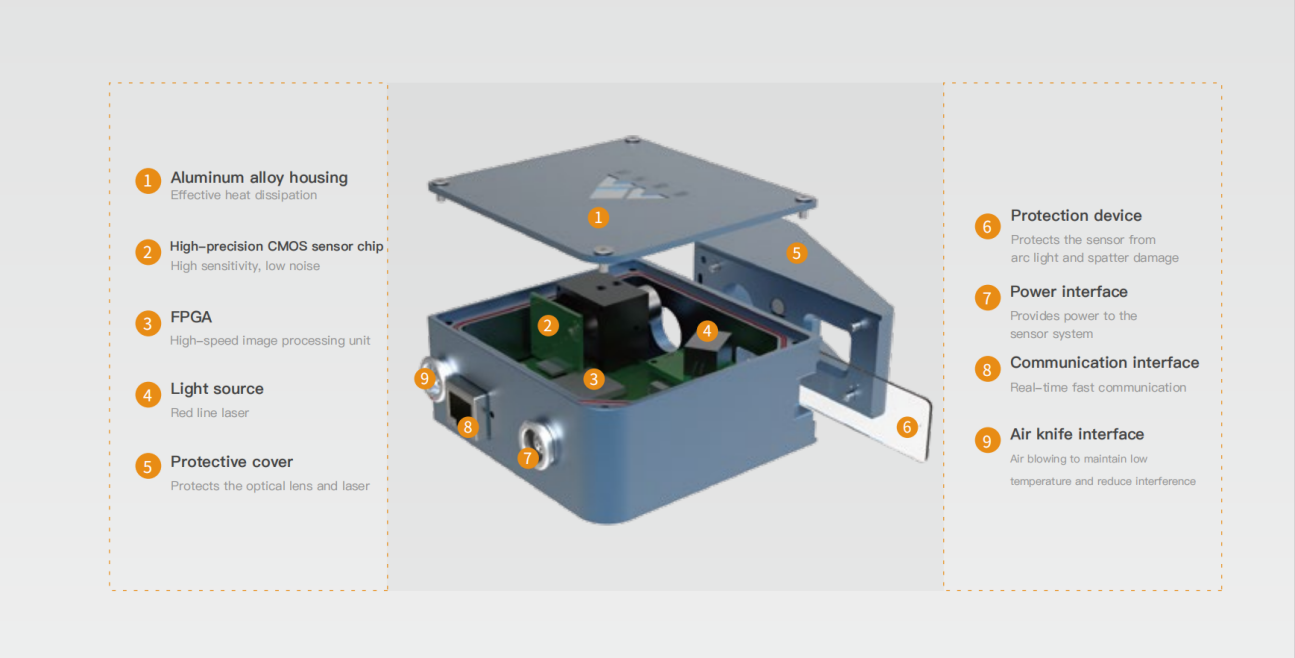

Cảm biến sử dụng đo lường ánh sáng cấu trúc tuyến tính, có tốc độ tạo hình nhanh, không tiếp xúc và không có chuyển động cơ học; Khả năng thích ứng mạnh mẽ, có thể xuất ra các thông số mối hàn; Toàn bộ hệ thống được nhúng, với máy tính công nghiệp bên ngoài và nhiều ưu điểm khác, được sử dụng rộng rãi trong các loại hàn tự động khác nhau. Bất kể quy trình hàn nào, chúng tôi có thể cung cấp sự hỗ trợ đáng tin cậy và hiệu suất ổn định để đảm bảo kết quả tuyệt vời trong các tình huống hàn khác nhau.

Cảm biến này phù hợp cho các ứng dụng đòi hỏi khắt khe nhất, vì nó không bị ảnh hưởng bởi ánh sáng杂rối, nước và bụi (IP67) và miễn nhiễm với bức xạ điện từ (EMC).

Với Chức năng Mạnh mẽ

01. hiệu chỉnh vị trí và sai lệch

Chức năng hiệu chỉnh vị trí và sai lệch được sử dụng cho các tình huống hàn linh hoạt của các chi tiết cùng kiểu nhưng có sai số không đồng nhất. Chức năng này đảm bảo rằng không cần can thiệp thủ công khi chuyển đổi chi tiết, và robot được hướng dẫn bởi hệ thống hiệu chỉnh vị trí và sai lệch để đạt được hàn chính xác.

Định vị hai điểm phù hợp với mối hàn lệch 2D theo đường thẳng.

Vị trí Đa Điểm Phù hợp cho các mối hàn 2D offset nhiều đoạn.

Vị trí Đoạn Phù hợp cho các mối hàn 3D offset nhiều đoạn.

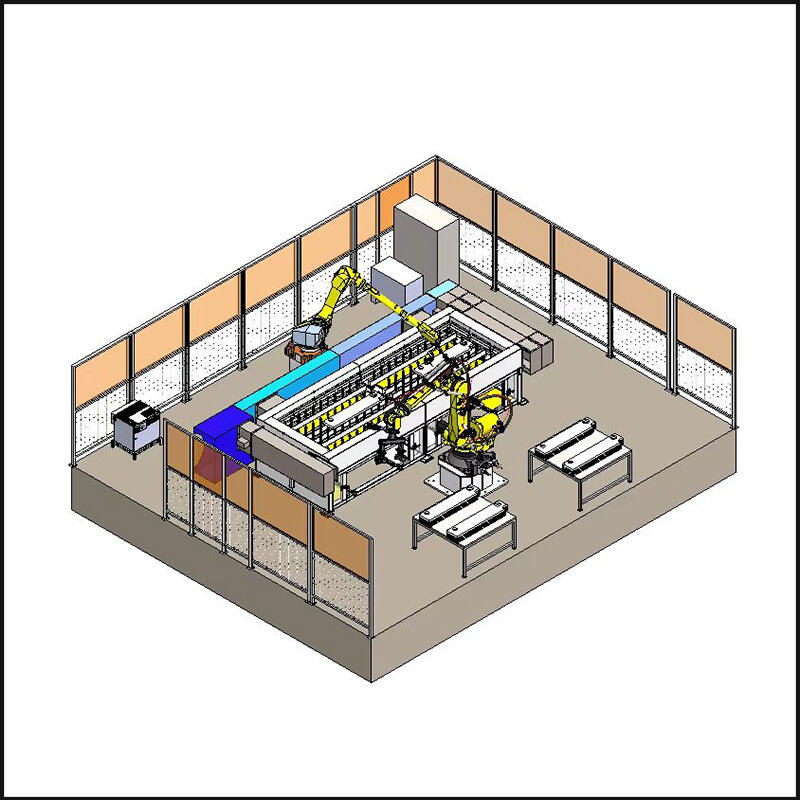

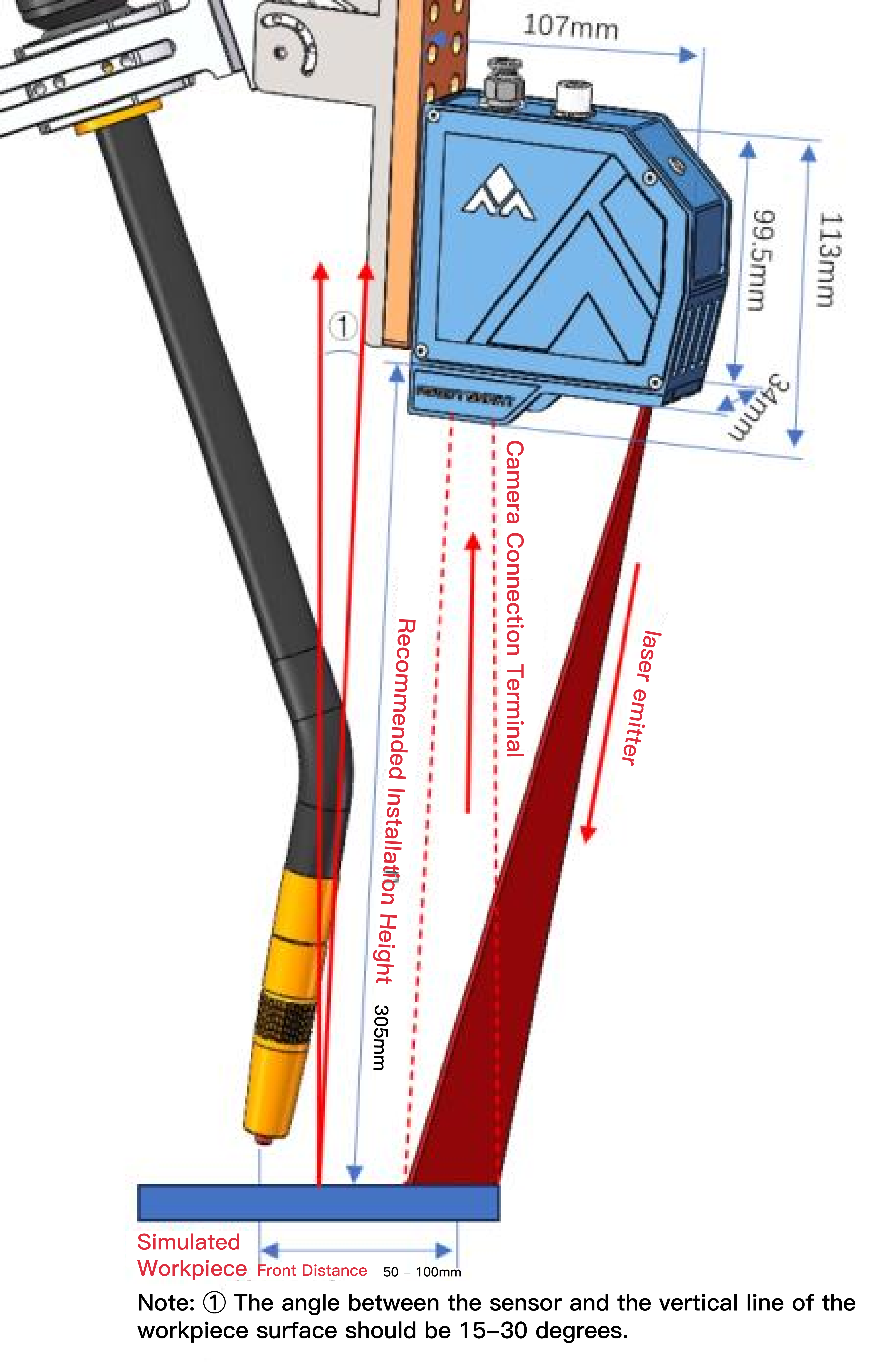

02 Theo dõi Thời gian Thật

Chức năng theo dõi thời gian thật được sử dụng trong các tình huống hàn yêu cầu hiệu suất cao và không có sự can thiệp không gian. Cảm biến được cố định tương đối với炬hàn, và炬hàn sẽ tự động điều chỉnh đường đi hàn dựa trên dữ liệu tọa độ 3D.

03. Quét và Hàn Tự động,

Chức năng quét và hàn tự động cho phép cảm biến thu thập thông tin hình học của các mối hàn trước tiên. Chức năng này phù hợp cho không gian hàn hẹp phản xạ cao và các tình huống hàn phức tạp.

Theo dõi Đường Hàn Laser

Theo dõi Đường Hàn Laser có thể phát hiện các sai lệch mối hàn lên xuống và trái phải.

Có thể phát hiện các mối hàn ghép có khe hở nhỏ.

Giải quyết vấn đề theo dõi mối hàn cho việc ghép tấm mỏng.

Khoảng cách quan sát tối ưu là khoảng 150mm.

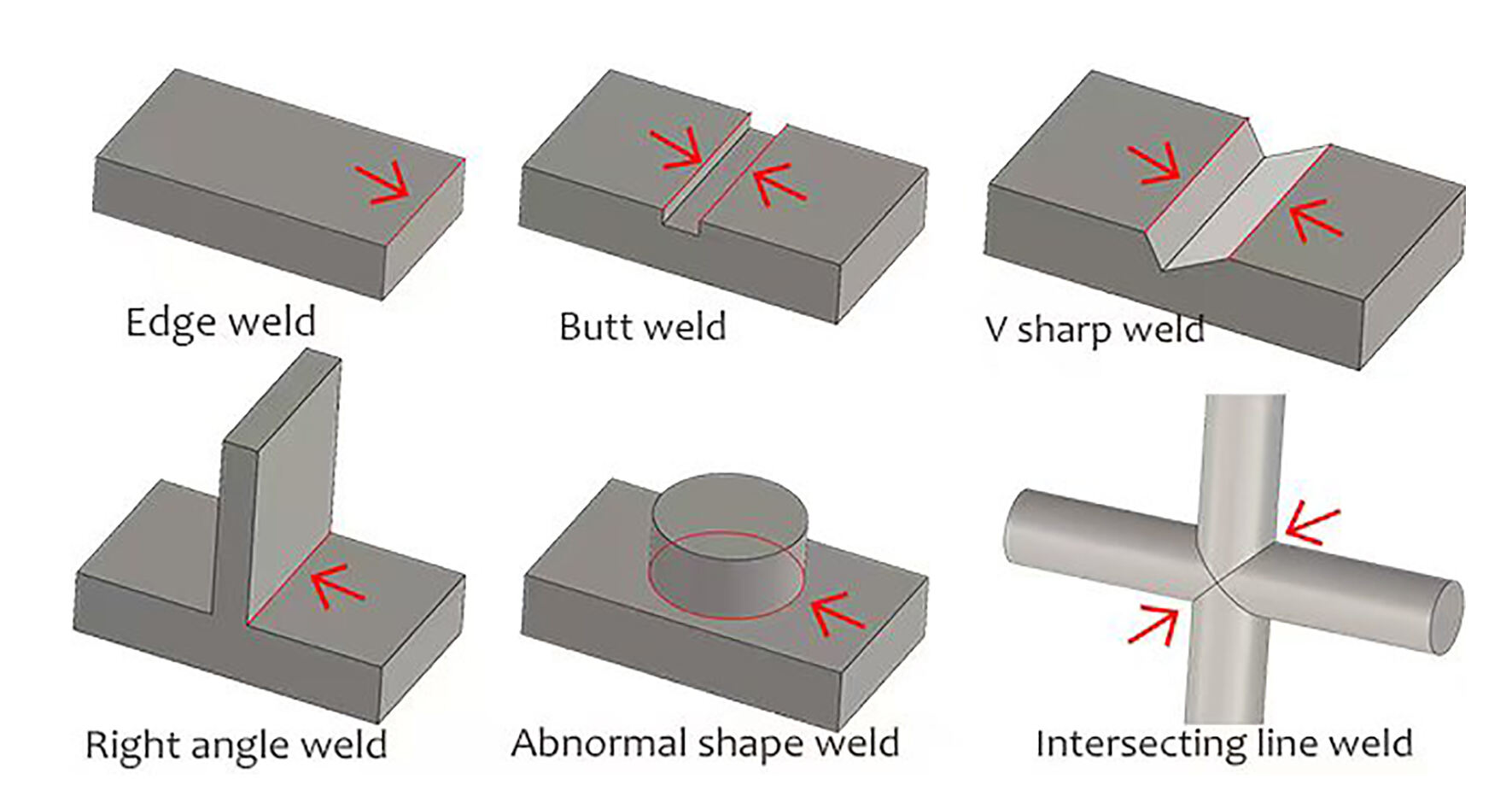

Loại hàn hỗ trợ

Hàn rãnh V

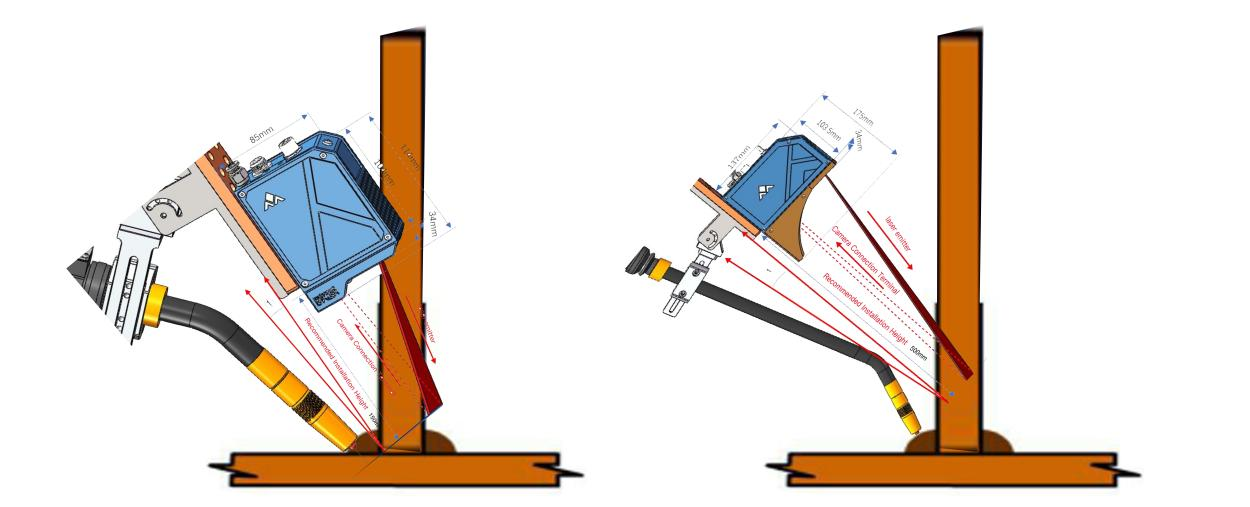

Hàn góc

Hàn gập mép

Hàn nối

Hàn chồng, v.v.

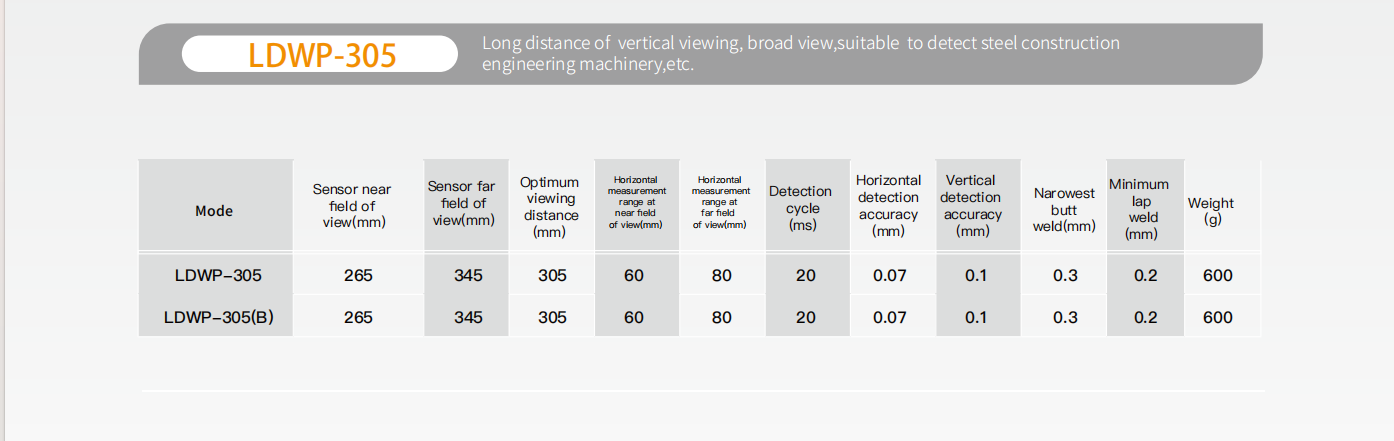

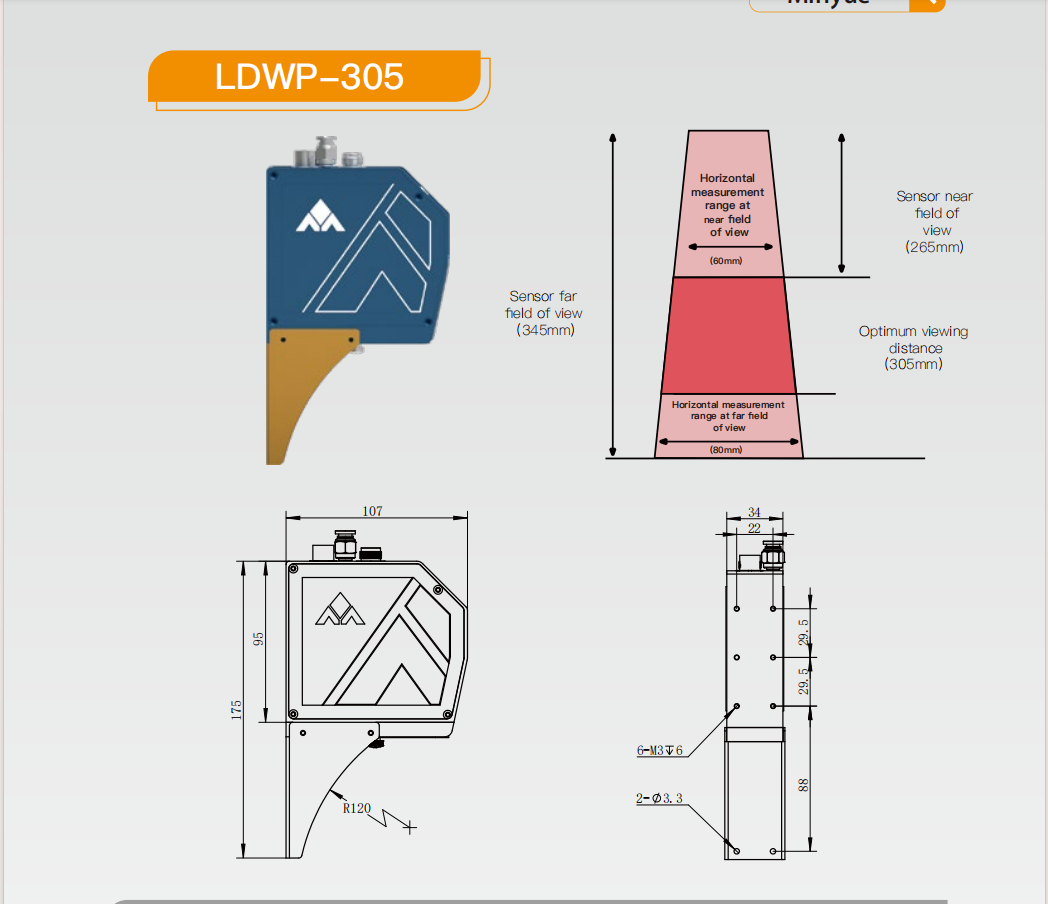

Khoảng cách quan sát dọc lớn, góc nhìn rộng, phù hợp cho ngành Kết Cấu Thép và Máy Thi Công.

Vui lòng chọn loại phù hợp theo phạm vi ứng dụng thực tế, để tránh va chạm giữa chi tiết công việc và cảm biến, tải trọng robot thường cần khoảng 20KG.

Đối tác hợp tác

Hỗ trợ thương hiệu robot

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK