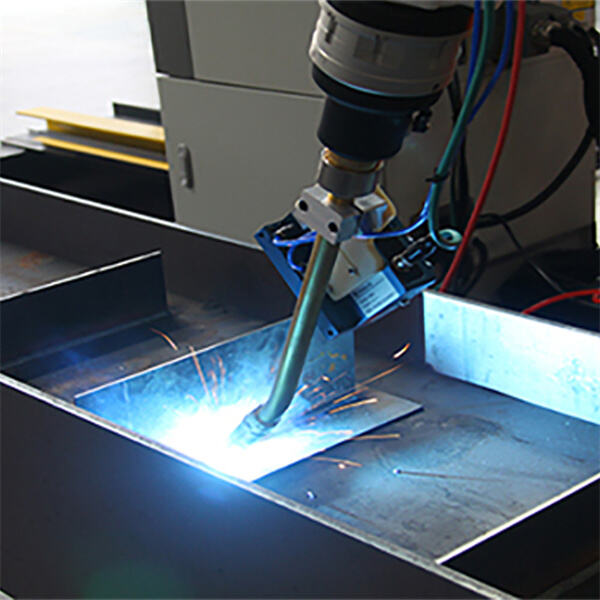

صنعتی ویلنگ روبوٹس کے بہت سارے مفید فوائد ہیں جو انھیں بہت مددگار بناتے ہیں۔ پہلے، یہ روبوٹس انسانی کارکنوں کی نسبت تیزی سے اور زیادہ دقت سے کام کر سکتے ہیں۔ کیونکہ استعمال کنندگان کو کام کرنے کی ضرورت ہوتی ہے ویلنگ روبوٹس کے اقسام

اس کے علاوہ، صنعتی ویلنگ روبوٹس کو شامل کرنا کمپنیوں کو تیز رفتار بازار میں رقابت کے حوالے سے قائم رہنے کی اجازت دیتا ہے۔ جب یہ ٹیکنالوجی کو کمپنیوں کے درمیان استعمال کرنے کی اضافہ ہو رہی ہے تو، یہ ٹیکنالوجی کو استعمال نہیں کرتی کمپنیاں رقابت میں قائم رہنے میں مشکل واقع کر سکتی ہیں۔ آج صنعتی ویلنگ روبوٹس میں سرمایہ کاری کرنا معاملوں کو مستقبل کے لئے سکون دینے کی ایک موقع دیتا ہے خودکار لگامی روبوٹ

صنعتی ویلنگ روبوٹس کو عمل میں لانے کی لاگت بہت زیادہ ہو سکتی ہے، اگر آپ اپنے روبوٹس کو موثر طور پر چلائیں اور مینیج کرنा چاہتے ہیں تو ہاں، لیکن آپ کو بتانا چاہئے کہ لاگت کیا شامل ہے۔ روبوٹس خود کو خریدنے کی بھی لاگت ہوتی ہے۔ یہ کسی بھی حد تک چند لاکھ سے لاکھوں ڈالر تک ہوسکتی ہے جو پیمانے پر منحصر ہے ویلنگ روبوٹس فɔر سیل

اور اس وقت جب آپ یہ روبوٹس اپنائیں گے تو شروعی خریداری کی لاگت سے زیادہ لاگت کو غور کرنے کی ضرورت ہے۔ نہ صرف کارکنوں کو تربیت دینے پر بھی روبوٹ ویلڈر فɔر سیل روبوٹ کے ساتھ سلامتی کے ساتھ کام کرنے کے طریقے۔ فirms کو بنیادی طور پر تحت سامان کو تیار کرنے کی ضرورت ہوگی، جو روبوٹ کے ساتھ کام کرسکتی ہے، جو اضافی لاگت کو واپس کر سکتی ہے۔

عمل کی لاگت، جیسے صنعتی ویلنگ روبوٹس کا استعمال، موجود ہیں۔ یہ چیزیں شامل ہیں جیسے مراقبت، تعمیرات، اور روبوٹ کے لیے ضروری کسی بھی اپگریڈز۔ خودکار روبوٹک ویلنگ . چاہے پہلی نظر میں یہ لاگت ڈرتی لگیں، لیکن یہ مहتمل ہے کہ.

تلاش اور ترکیب کے فنکشن کو اپنائیں، چڑیا جوڑنے کی سیم کو اسکین کریں، چڑیا جوڑنے کی سیم کی پوزیشن اور معلومات کو تصدیق کریں، 3D ڈجیٹل ماڈل ڈرافٹ اور حقیقی ورک پیس کے درمیان چڑیا جوڑنے کی پوزیشن کو مطابقت دیں، اور داخلہ مواد کی غلطی اور گرما کی تبدیلی کی وجہ سے چڑیا جوڑنے کی مسئلہ حل کریں۔

بیجنگ مینیو ٹیکنالوجی کمپنی، لمیٹڈ، صنعتی روبوٹس کے غیر تعلیمی ذکی اطلاق کے عالمی نمائندہ بلند ترین ٹیکنالوجی کمپنی ہے۔ ہم خود شروع کردہ RobotSmart - ذکی فیصلہ سازی نظام، SmartVision - دونوں چشم ساختی روشنی وژن نظام، اور SmartEye - لیزر وژن سیم ٹریکنگ نظام پر تخصص رکھتے ہیں۔ نئی پیداوار ذکی روبوٹ چڑیا جوڑنے اور کٹنے کے حل فراہم کرتے ہیں۔

قدرتمند ویلنگ روبوٹ فراہم کرتا ہے آگے لوڈنگ، سائیڈ لوڈنگ، معکوس لوڈنگ، گینٹر Маунٹنگ، متعدد روبوٹس کے لئے ذکی مسیر تجویز، متعدد بیرونی محور، اور پوزیشنر برائے معاونت کام کے لئے۔ روبوٹ موشن سمولیشن، ٹکر کا شناسہ، منفردیت کا بازی کرنا اور محور حد شناسائی کو حاصل کریں۔

تیزی سے، مکمل طور پر براہ راست، کم کارلگی اور بالکل تجزیاتی ٹیچنالوجی۔ یہ تقسیم کرتا ہے سافٹ ویئر کو مشکل بنانے والے عمل کو اور ٹیچنالوجی کے عمل کو روکنے سے بچاتا ہے۔