Tümümüz, robotlarla çalışmanın zor olabileceğini biliyoruz, ancak doğru bilgiye sahip ve biraz pratik yapırsanız bu çok kolay hale gelebilir. MINYUE, robotları nasıl ele alacağınızı size öğretmek ve bunu mümkün olan en iyi şekilde yapmak için burada. Bu kılavuz, nasıl operasyon yapacağınızı robot eleme sistemi , hareketlerini nasıl kontrol edeceğinizi ve bunu nasıl güvenli ve verimli bir şekilde yapacağınızı ele alacaktır.

Öncelikle, farklı türlerdeki robotlar hakkında her şey. Bilmeniz gereken iki ana türde robot vardır: sabit robotlar ve hareketli robotlar. Sabit robotlar konusunda bahsedildiğinde, hiç hareket etmeyen olanlardır. Genellikle fabrikalarda bileşenleri birleştirmek gibi görevler için kullanılırlar. Bunun karşıtı olarak, hareketli robotlar çevreyi taramak ve yer değiştirmek için tasarlanmıştır. Bu robotlar, genellikle teslimat veya temizlik amaçlı kullanılan mobil bir robot türüdür. Bu konuda olan türler arasındaki farkı anlamak, size doğru robotu seçmenizi sağlar ve yapmanız gereken işe uygun robotu belirlemenizi kolaylaştırır.

Şimdi bir MINYUE robotunu kontrol etme konusunda konuşalım. Robotu hareket ettirmek için kullanılan temel arabirim, joystick veya tüm dört yönde hareketi kontrol etmek için kullanılabilen bir dizi düğme olabilir. Kontrollerle alıştırma yapmak çok önemlidir, böylece robotun nasıl hareket ettiği ve yanıt verdiğini öğrenersiniz. Robot, kod adı verilen talimat parçaları yazarak programlanabilir. Bu kod, robota nasıl hareket edeceğini ve hangi görevleri yerine getireceğini söyler. Robotları ustaca kullanabilmek için, şu anda çekirdek bir beceri olan programlamayı öğrenebilmeniz gerekir.

Ayrıca, robotların karmaşık şekilde hareket etme gereksinimi de bulunmaktadır ve bu daha da karmaşık olabilir. Bazıları oldukça zor olduğu için, bunları yönetilebilir parçalara ayırmaya çalışırız. Örneğin, bir odanın bir ucundaki bir robotu diğer ucuna götürmek isteyelim. İlk olarak, robotun doğru yöne baktığından emin olmak için yeniden yönlendirmeniz gerekebilir. Daha sonra onu biraz ileri çekersiniz ve ardından döndürürsünüz, böylece gitmesi gereken yere ulaşır. Bu, MINYUE otomatik mal taşıma robotları robotu kontrol etmeyi kolaylaştırır. Ayrıca, çevresini anlaması için robotlarda sensörler kullanabilirsiniz. Sensörler, robotun engellerden kaçınmasına ve daha滑smoothçe navigate navigasyon yapmasına yardımcı olur, böylece işinizi eleman olarak daha kolay hale getirir.

Robot kontrolünde uzmanlaşmaktan kaçınmakla geçirilen her zaman, kaybedilmiş zaman demektir. Ve ne kadar fazla antrenman yaparsanız, robota o kadar daha fazla alışır ve kontrol ederken güvende hissedersiniz. Ayrıca robotun programlamasını ince ayarlayarak becerilerinizi geliştirebilirsiniz. Yazdığınız kodda küçük değişiklikler yapabilir, robotun hareketlerini daha iyi hale getirebilir ve işleri daha verimli bir şekilde yapmasını sağlayabilir. Düzenli pratikle ve gerektiğinde yapılan değişikliklerle, robotu kullanma becerilerinizin sizin için kol robotu kaynatacı olduğu gibi büyük ölçüde artacak.

Robotlarla çalışırken, güvenli olmak en önemli önceliklerden biridir. Kendinizi ve diğerleri korumak için her zaman güvenlik kurallarını ve prosedürlerini takip edin. Robotlarla çalışırken çevrenizle ilgili dikkatli olmalısınız, çünkü bazen uyarı vermeden hareket edebilirler. İşlem akışını kolaylaştırmak için, uygun robotun gerekli işi yaptığından emin olun. Örneğin, ağır nesneleri taşıma gerekiyorsa, daha ağır yükler kaldırmaya ve taşımaya tasarlanmış bir robot kullanmalısınız. Ayrıca, sensörler ve otomasyon size daha az zaman ve enerjiyle daha fazla şey yapmanıza olanak tanır. Otomasyon, size zaman kazandırır ve işinizi kolaylaştırır.

Hızlı, doğru, tamamen Programsız, yüksek verimlilik ve yüksek hassasiyet. Geleneksel robotların karmaşık öğretim süreçlerini çözer ve öğretim sürecindeki duruş zamanını tasarruf eder.

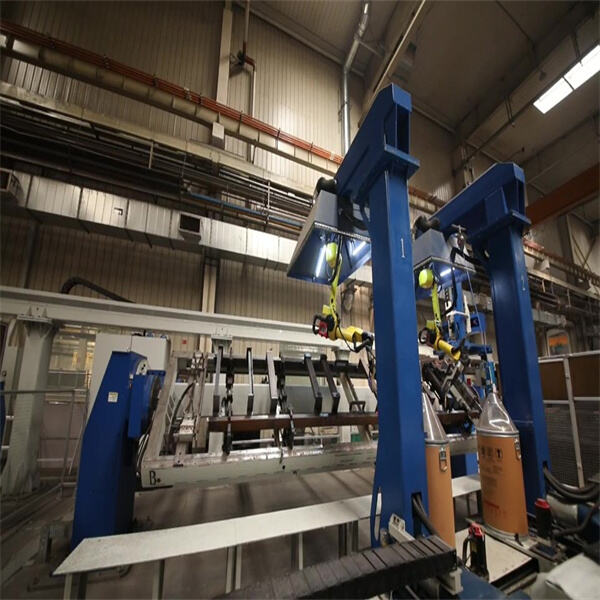

Beijing Minyue Technology Co.,LTD, dünyanın önde gelen yüksek teknoloji firmalarından biridir ve endüstri robotlarının öğretimsiz zeka uygulamalarında uzmandır. Kendi geliştirdiğimiz RobotSmart - Zeka Karar Verme Sistemi, SmartVision - Çift Gözlü Yapılandırılmış Işık Görüş Sistemi ve SmartEye - Laser Görüş Duvar İzleme Sistemi ile esnek zeka üretimi üzerine uzmanlaşmıştık. Yeni nesil zeka robot kaynaklama ve kesme çözümleri sunuyoruz.

Güçlü kaynak robotu için ön yükleme, yan yükleme, ters yükleme, konsol montajı, birden fazla robot için zeka yoluyla hareket planlama, birden fazla harici eksen ve konumlandırıcı işbirliği için entegre çalışabilirlik sağlar. Robot hareketi simülasyonunu, çarpışma algılama, tekil nokta önleme ve eksen sınırı algılama gerçekleştirmeyi sağlar.

Bulma ve izleme fonksiyonlarını kullanarak kaynak ekranını tarama, kaynak ekranının konumunu ve bilgilerini doğrulama, 3B dijital model çizimi ile gerçek parça arasındaki kaynak ekranı konumunu düzeltme ve gelen malzeme hataları ve termal deformasyon nedeniyle ortaya çıkan sapmalı kaynağı çözmek için kullanılır.