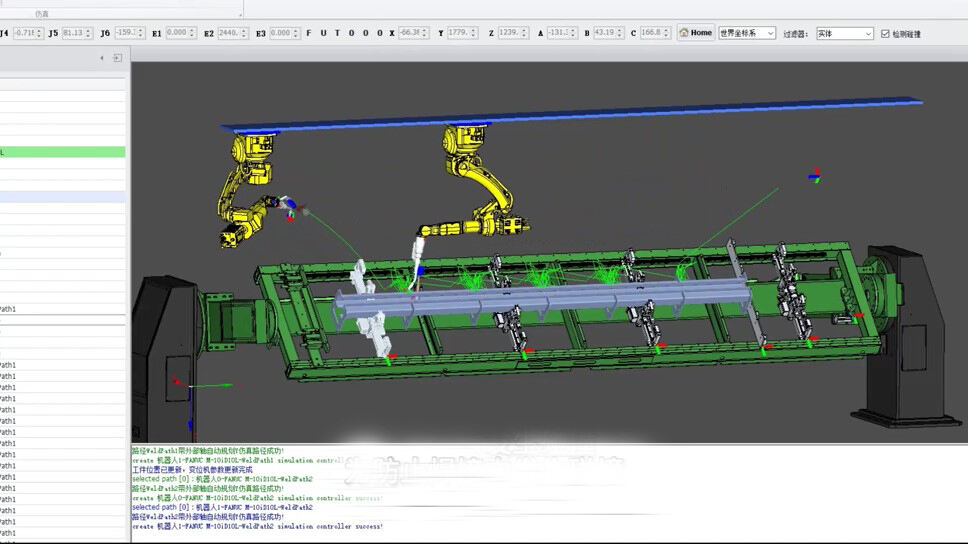

Platahang simulasyon para sa offline programming ng industriyal na mga robot

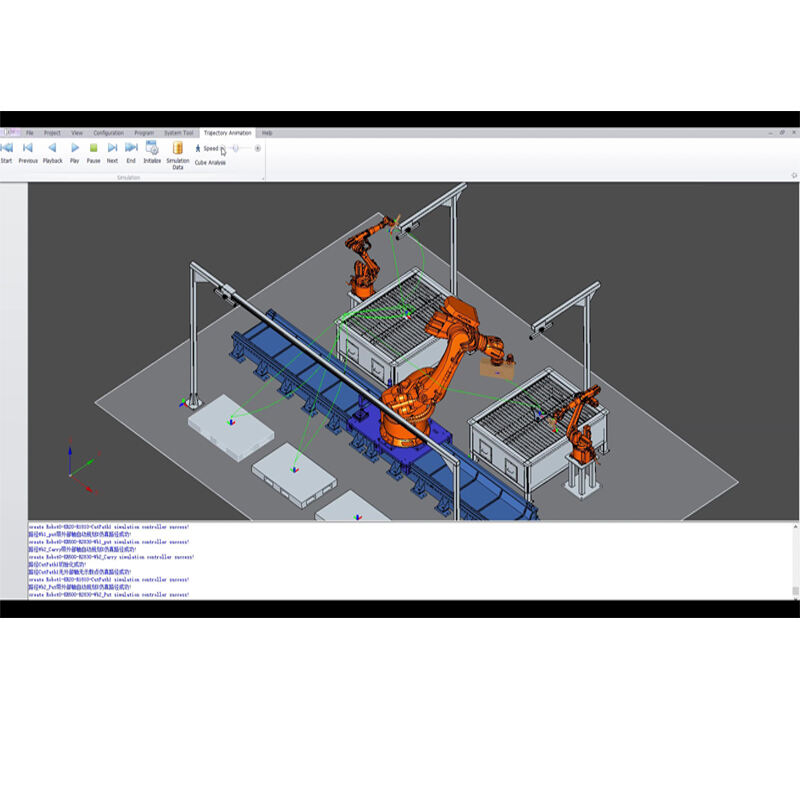

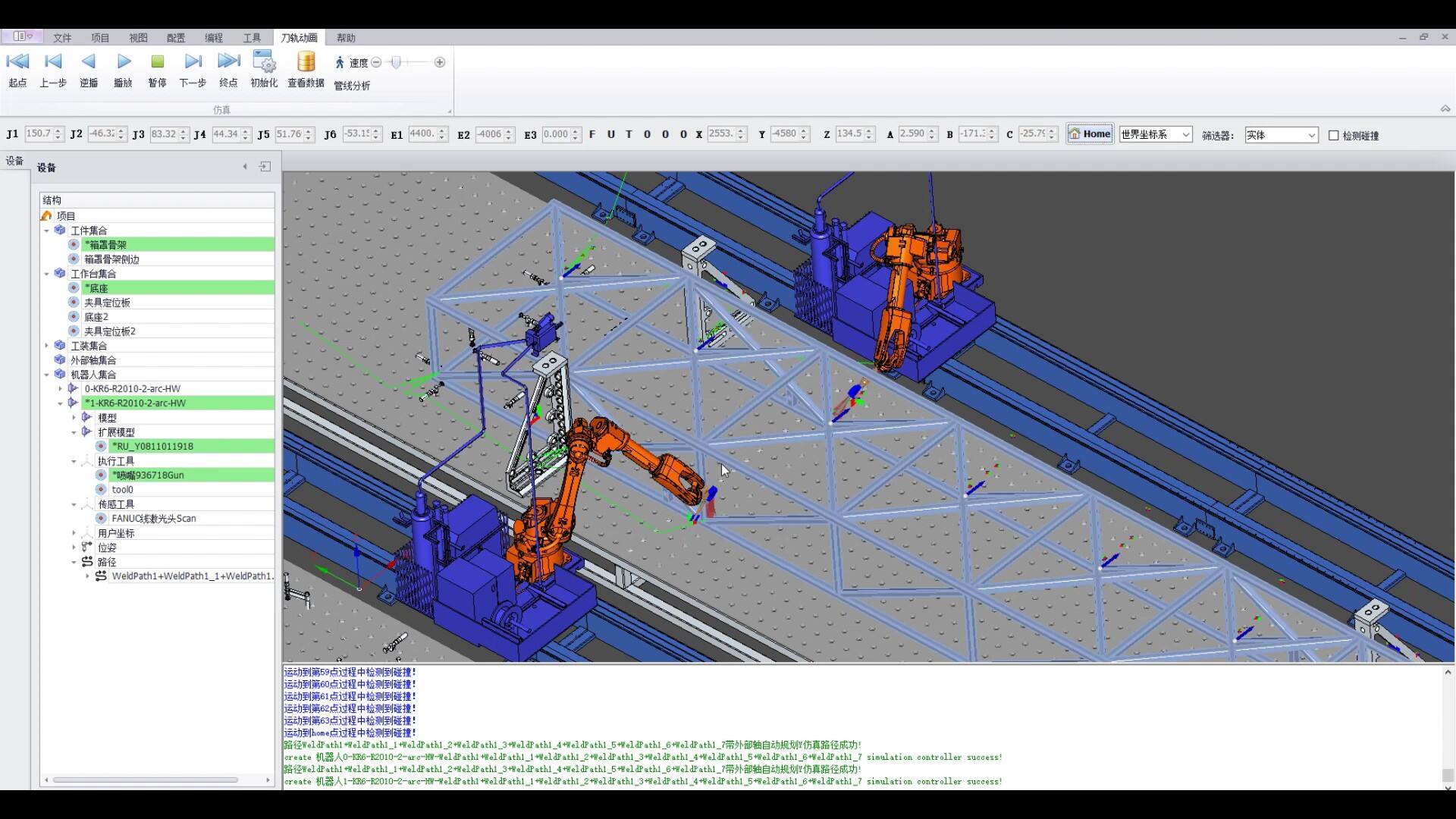

Awtomatikong pag-generate ng robot motion code, maraming mga robot, maraming panlabas na axis, positioner, nagtatrabaho nang magkasama. Maaaring mag-plano ng pinakamalaking 24 axis trajectory. Nagpapatakbo ng simulasyon sa paggalaw ng robot, deteksyon ng kollisyon, pagiwasan ng singularity at deteksyon ng limitasyon ng axis.

- Panimula

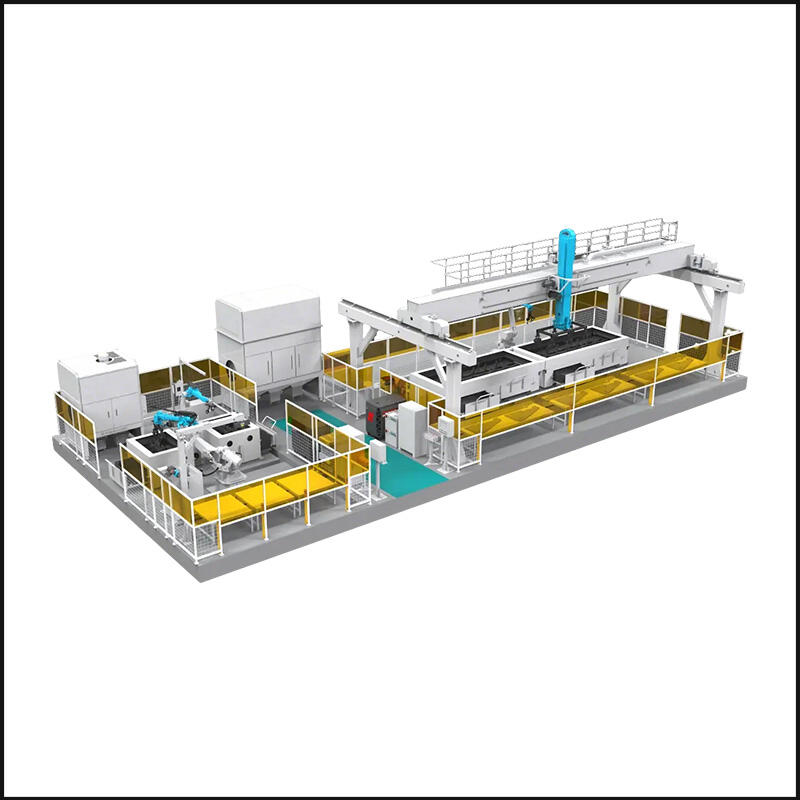

Ang sistemang pangkontrol ng intelihenteng pagweld na walang pagtuturo ng MINYUE Technology ay nakabubuhay sa larangan ng robotikong awtomatikong pagweld na may maraming taon ng karanasan. Upang sulusan ang sakit ng industriya. Halimbawa, ang pagsisimula ng kakulangan ng manggagawa ng pagweld, hindi sapat na katumpakan ng mga parte sa pag-unload at pag-ayos, maraming hindi pamantayan at maliit na dami ng trabaho na kinakailangan sa konstraksyon ng bakal, paggawa ng barko, mahahabang industriya, paggawa etc. Ito ay nag-aalok ng solusyon sa intelihente na pagweld na kilala sa kabuuan at walang pagtuturo.

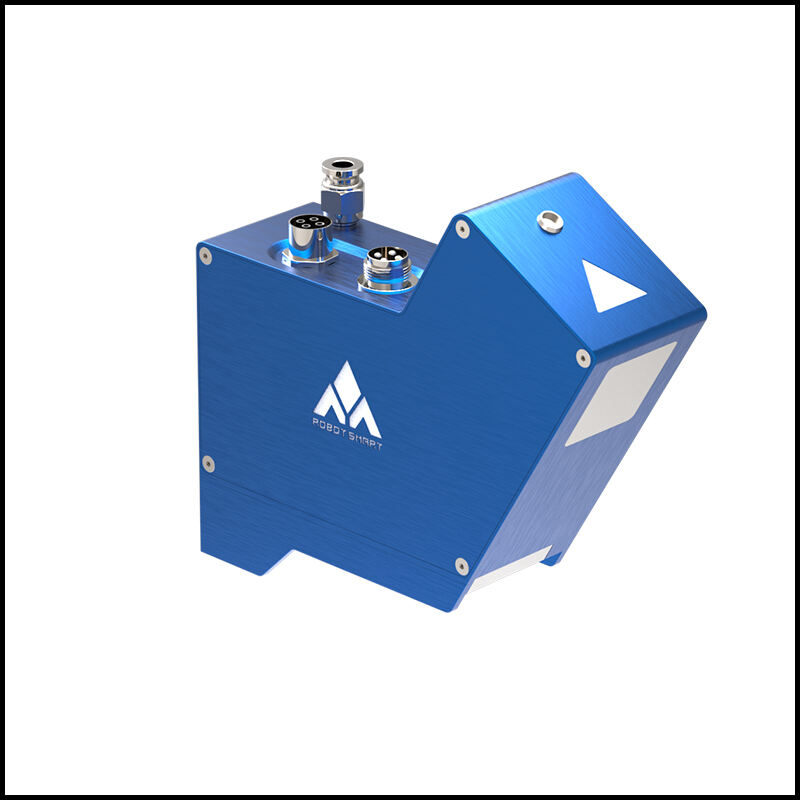

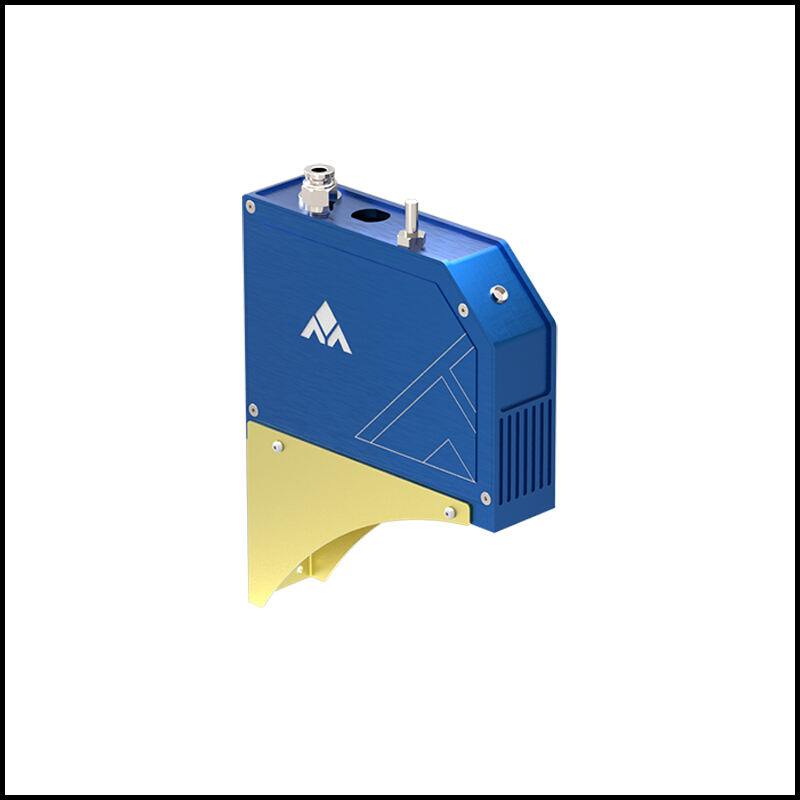

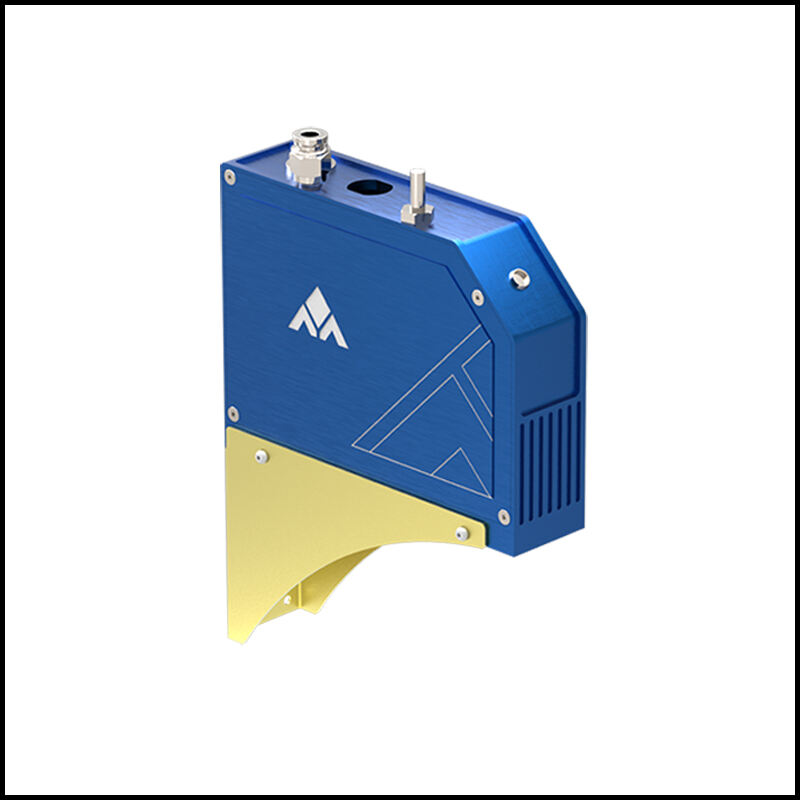

RobotSmart, ang sistema ng pangangailusin mula kay MinYue, maaaring mabilis na maglikha ng mga trayektoriya ng robot, epektibong naglulutas ng mga problema tulad ng komplikadong pagtuturo ng trayektoriya ng pagsasaldang, mababang kasiyahan sa pamamaraan, mababang paggamit ng mga robot at iba pang mga problema sa lokohan ng pag-programa.

Ang Robotsmart Intelligent Decision System ay nagpaproduko ng mga puntong trajektoriya para sa paghuhusay at kanilang mga posisyon sa pamamagitan ng pagsasama ng 3D digital na modelo ng workpiece sa software at pagsisiyasat ng mga punto, linya at ibabaw sa 3D modelo, pati na rin ang paggawa ng programa para sa robot na maaaring gamitin agad sa bahagi ng robot, isang point cloud model para sa visual na lokalisasyon, at ang nilikha na user coordinate system.

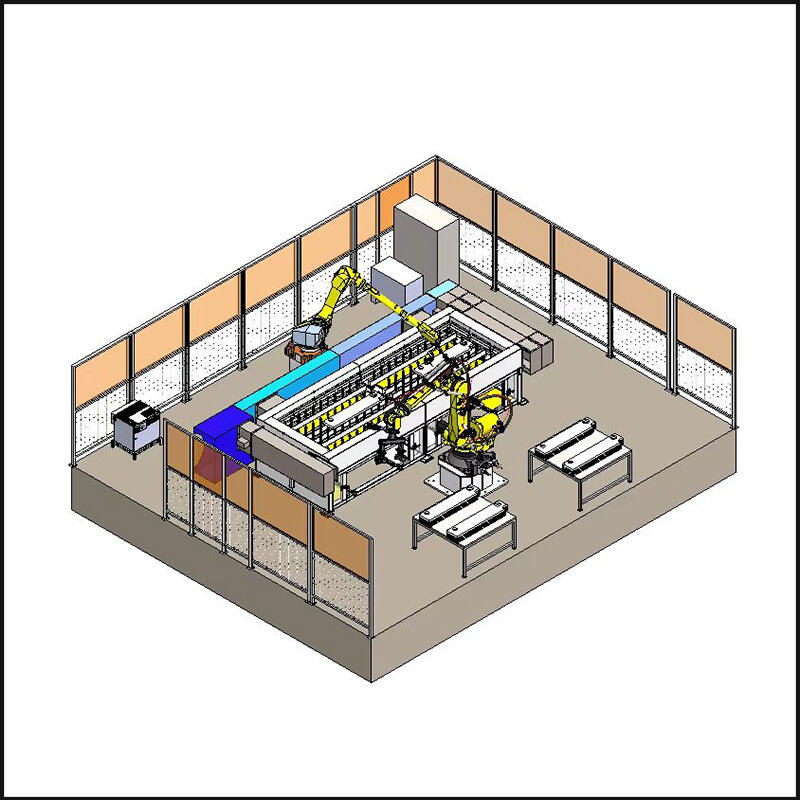

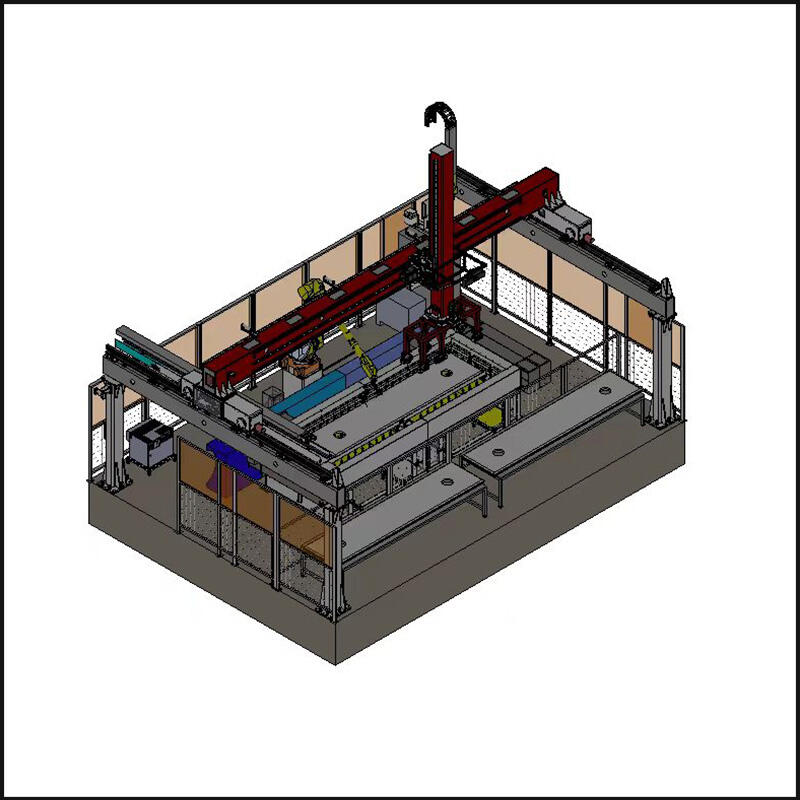

Ang offline programming software para sa mga robot ay nagbibigay-daan sa pag-modelo at simulasyon ng mga robot, Workcells, at mga production line, pati na rin ang deteksyon ng kollisyon. Ito ay nag-iintegrasyon ng mga karaniwang algorithm packages para sa mga robot, kabilang ang kinematics, dynamics, trayektoriya planning, trayektoriya optimization at iba pa. Ang simulasyon ng offline programming software ay maaring makamit ang parehong oras na sinkronisasyon at trayektoriya running effect tulad ng tunay na controller, na nagpapakita ng tunay na offline programming. Ang mga resulta ng programming ay maaaring magbigay ng iba't ibang robot command languages at i-download sa tunay na controller para sa operasyon.

Pangunahing Mga Tampok

Ang modularity ay maaaring ipagkamulatan: ang software ay naka-modular upang pasadya ang mga magkakaibang pangangailangan ng mga kliyente.

Deteksyon ng Pagbabagsak at Pagkuha ng Layo: mabilis na mapapatunay ang pagkuha ng pinakamaliit na layo ng modelo ng simulasyon at kung may pagbabagsak o hindi.

Deteksyon ng Pagbabagsak at Pagkuha ng Layo: mabilis na mapapatunay ang pagkuha ng pinakamaliit na layo ng modelo ng simulasyon at kung may pagbabagsak o hindi.

Kinematics ng Papanood at Inverso: Suporta sa pampalawig na algoritmo para sa kinematics ng papanood at inverso ng mga series-parallel mechanisms.

Dinamika: pampalawig na mga algoritmo ng dinamika para sa pagsasabisa ng series-parallel mechanisms.

Algoritmo ng Pagplano ng Trahektorya: maaaring awtomatikong plano ang mga walang-pagbabagsak na trahektorya ng robot.

Algoritmo ng Optimizasyon ng Trahektorya: pagsisimula ng optimizasyon ng trahektorya ng robot upang maiwasan ang oras at enerhiya offline.

Virtual na Controller: Nagpapatakbo ang virtual na controller ng presisyong kontrol ng oras at trahektorya, at ang epekto ng simulasyon ay katulad ng tunay na controller.

Suporta sa maramihang posisyoner, maramihang panlabas na axis.

Maayos na itatayo ang iba't ibang mga scenario ng simulasyon.

Kinakamkam sa loob 100+ modelo ng robot, maaaring magtrabaho kasama ang lahat ng modelo mula sa apat na malalaking kompanya ng robot at regular na pambansang mga brand.

Kailangan lang ng 1~2 araw para matapos ang pag-debug sa komunikasyon ng robot, mas maikli ang siklo ng pag-debug at mas mababang kos ng pag-debug.

tatlóng-dimensyonal na digital na modelo

Handa - offline programming nang walang downtime. Ang production program para sa susunod na araw, linggo, o buwan ay maaaring gawin ahead of time upang tugmaan ang Mes scheduling plan.

Epektibo, walang teaching, parametrikong, grapikal na programming, awtomatikong paggawa ng programa loob ng 30 minuto na nagbababa ng threshold ng paggamit.

Matalino - paggagawa ng ulat sa regular na panahon at pagsasabid ng mga exception. Real-time na update at pamamahala ng datos ng parts library, parameter library, at project library.

Awtomatikong pag-generate ng robot motion code, maramihang mga robot, maramihang panlabas na mga axis, posisyoner, nagtatrabaho nang magkasama. Maaaring iplan ang trayektoriya ng pinakamataas na 24 axis.

Nagpapatakbo ng simulasyon sa paggalaw ng robot, deteksyon ng kollisyon, pagiwasan ng singularity at deteksyon ng limitasyon ng axis.

Deteksyon ng kollisyon, pagiwasan ng singularity at deteksyon kung maabot ang trabahong lugar. Simulasyong pagsusuri, solusyon sa isang-pindot para sa kollisyon, singularity, labis na paglakbay at hindi maabot.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK