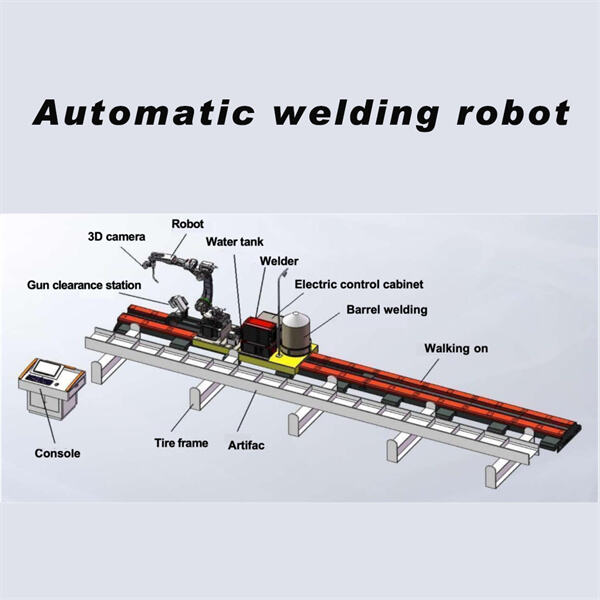

สิ่งนี้จะลดความเสียหายต่อการผลิตลง ในขณะที่การทำให้มันเป็นหนึ่งในวิธีที่ดีที่สุดในการทำงานเชื่อมคือการใช้หุ่นยนต์เชื่อม ที่ MINYUE นั่นคือสิ่งที่เราเชื่อ ซึ่งทำให้คุณอาจสงสัยว่า หุ่นยนต์เชื่อมคืออะไร? เครื่องจักรเหล่านี้ถูกเรียกว่าหุ่นยนต์เชื่อม เครื่องจักรเฉพาะทางที่สามารถฝึกฝนให้ทำภารกิจเชื่อมซ้ำๆ ได้ หุ่นยนต์เชื่อมสำหรับขาย

สิ่งที่สวยงามเกี่ยวกับกระบวนการอัตโนมัติในการเชื่อมคือ หุ่นยนต์มีบทบาทในการเร่งการผลิตขณะรักษาความแม่นยำอย่างยอดเยี่ยม แล้วมันหมายถึงอะไรเมื่อคุณใช้หุ่นยนต์ในการทำสิ่งต่าง ๆ เช่น การเชื่อม? มันหมายความว่าหุ่นยนต์สามารถเพิ่มประสิทธิภาพและทำงานซ้ำได้อย่างรวดเร็วกว่ามนุษย์อย่างมาก เรื่องสำคัญที่สุด ประเภทของหุ่นยนต์เชื่อม

ไม่เพียงแค่นั้น หุ่นยนต์เชื่อมยังสามารถประหยัดเงินจำนวนมากได้อีกด้วย หุ่นยนต์เหล่านี้สามารถทำงานเป็นชั่วโมง ๆ ตลอด 24 ชั่วโมงโดยไม่ต้องพักหรือนอน ซึ่งหมายความว่าคุณไม่จำเป็นต้องจ่ายค่าแรงล่วงเวลาให้กับพนักงาน ซึ่งเป็นประโยชน์อย่างมากสำหรับธุรกิจเพราะลดต้นทุนแรงงาน นอกจากนี้ หุ่นยนต์ยังสามารถทำงานในพื้นที่ที่อันตรายเกินไปสำหรับ การตัดพลาสมาด้วยหุ่นยนต์

นอกจากนี้ การใช้หุ่นยนต์เชื่อมยังทำให้งานปลอดภัยขึ้นสำหรับพนักงาน เมื่อทำการเชื่อมที่ซับซ้อน พนักงานมนุษย์อาจเสี่ยงต่อสภาวะอันตราย เช่น เคมีพิษ วัสดุที่ร้อนมาก และอันตรายอื่นๆ หุ่นยนต์เชื่อมของคุณลดความเสี่ยงของการบาดเจ็บของพนักงาน ซึ่งหมายถึงอุบัติเหตุในที่ทำงานน้อยลงและสภาพแวดล้อมที่ปลอดภัยกว่ามาก เมื่อพนักงานรู้สึกปลอดภัย พวกเขาสามารถมุ่งเน้นกับงานได้มากขึ้นและมีประสิทธิผลมากขึ้น

งานเชื่อมแต่ละงานแตกต่างกัน ดังนั้นอาจต้องใช้วิธีการที่แตกต่างกัน ซึ่งเป็นเหตุผลที่เราเสนอตัวเลือกการเขียนโปรแกรมเฉพาะสำหรับแอปพลิเคชันการเชื่อมของคุณ หากคุณซื้อหุ่นยนต์เชื่อมจากเรา เราจะร่วมมือกับคุณเพื่อเขียนโปรแกรมหุ่นยนต์ของเราให้เหมาะสมกับงานที่คุณต้องการให้มันทำ ซึ่งจะทำให้คุณได้หุ่นยนต์ที่ปรับแต่งมาโดยเฉพาะสำหรับงานเชื่อมจุดของคุณ

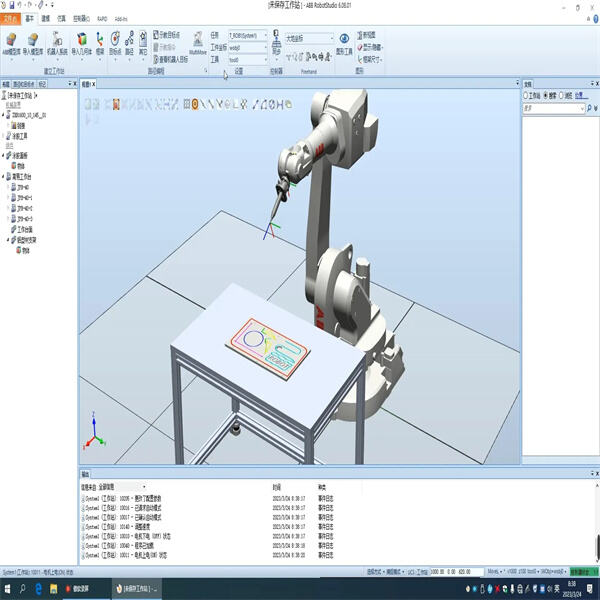

การใช้งานฟังก์ชันการค้นหาและการติดตาม การสแกนรอยเชื่อม การยืนยันตำแหน่งและข้อมูลของรอยเชื่อม การปรับตำแหน่งของรอยเชื่อมระหว่างแบบจำลองดิจิทัล 3D กับชิ้นงานจริง และแก้ปัญหารอยเชื่อมที่เบี่ยงเบนเนื่องจากความผิดพลาดของวัสดุที่เข้ามาและการเสียรูปจากความร้อน

รวดเร็ว แม่นยำ ไม่ต้องเขียนโปรแกรมเลย มีประสิทธิภาพสูงและแม่นยำสูง แก้ไขกระบวนการสอนที่ซับซ้อนของหุ่นยนต์แบบดั้งเดิมและประหยัดเวลาหยุดทำงานจากการสอน

ให้บริการหุ่นยนต์เชื่อมประสิทธิภาพสูงแบบโหลดด้านหน้า โหลดด้านข้าง โหลดกลับหัว ติดตั้งบนโครงเหล็ก วางแผนเส้นทางอัจฉริยะสำหรับหุ่นยนต์หลายตัว แกนภายนอกหลายแกน และตำแหน่งการทำงานร่วมกัน สามารถจำลองการเคลื่อนไหวของหุ่นยนต์ ตรวจจับการชนหลีกเลี่ยงจุดเอกฐาน และตรวจสอบข้อจำกัดของแกนได้

บริษัท Beijing Minyue Technology Co.,LTD ในฐานะผู้นำด้านเทคโนโลยีสูงระดับโลกสำหรับการประยุกต์ใช้หุ่นยนต์อุตสาหกรรมแบบไม่มีการสอน เราเชี่ยวชาญในการผลิตแบบการผลิตอัจฉริยะที่ยืดหยุ่นด้วยระบบ RobotSmart - ระบบการตัดสินใจอัจฉริยะ, SmartVision - ระบบวิชั่นแบบแสงโครงสร้างสองตา และ SmartEye - ระบบติดตามรอยเชื่อมด้วยเลเซอร์ ให้โซลูชันการเชื่อมและการตัดด้วยหุ่นยนต์อัจฉริยะรุ่นใหม่