Smart 3D vision sensors are awesome tools that enable machines to better understand their surroundings. These binocular structured light vision sensors employ that patented technology to image objects in three dimensions, allowing them to see how things appear from multiple perspectives. Mimicking the way our eyes let us see and learn about the surrounding world, it allows these organisms to make intelligent decisions and execute functions with high precision. Like the eyes of a robot, they help it navigate safely, do tasks gently, be it lifting something or navigating its way around a room.

Generative AI for Smart 3D Vision Sensors technology in everyday life They are used in a variety of scenarios, from self-driving cars that can operate without a human driver to smart homes that can automatically help adjust the lighting or temperature. These sensors can detect obstacles in their path, identify faces of humans, and estimate distances between objects possible. MINYUE advanced 3D vision sensors and laser vision sensor allow machines to perform complex tasks quickly and accurately to make our life easier and more comfortable. For instance, these sensors can help a robot detect when to stop so it does not crash into an object, ensuring safety for both the robot and it is surroundings.

In what fields could smart 3D laser vision sensor be used? They can assist in many roles, such as in health care, manufacturing and entertainment. With these sensors, doctors can easily perform surgery with more caution and precision in healthcare, which is significant to ensure patient safety. They can help manufacturers ensure products are produced properly so they can track mistakes in the process. In entertainment, they can help create immersive experiences for people, whether that’s making video games more realistic or virtual reality experiences more thrilling. Smart 3D vision sensors are being used and will become even better with time as technology evolves and improves.

There are a lot of advantages of MINYUE 3D intelligent vision sensors that help mankind and the sector. They can optimize things, minimize errors, and even enhance safety in various fields. For instance, in the automotive space, these sensors can make vehicles avoid collision by detecting obstacles on the road, be it pedestrians or other vehicles. This is what you do to keep everyone safe. In agriculture, they can allow farmers to monitor the status of their crops and detect early problems (such diseases or pests) that they can treat before they are out of hand. Using powerful smart 3D vision sensors is serving the society in many ways, improving and making our lives easy.

In the world of MINYUE 3D machine vision, 3D smart vision sensors are becoming the true architects for the future. They are also helping to come up with new ideas and altering the way businesses function, making it quicker, more precise, and all around better in what we do. From healthcare to manufacturing and entertainment, these sensors are altering the way that we live and work every day. Smart 3D vision sensors will become an even more critical component of the future as technology continues to advance and thrive. They are likely to be involved in a significant part of our quotidian existence, assisting us with activities we undertake at home and in different positions.

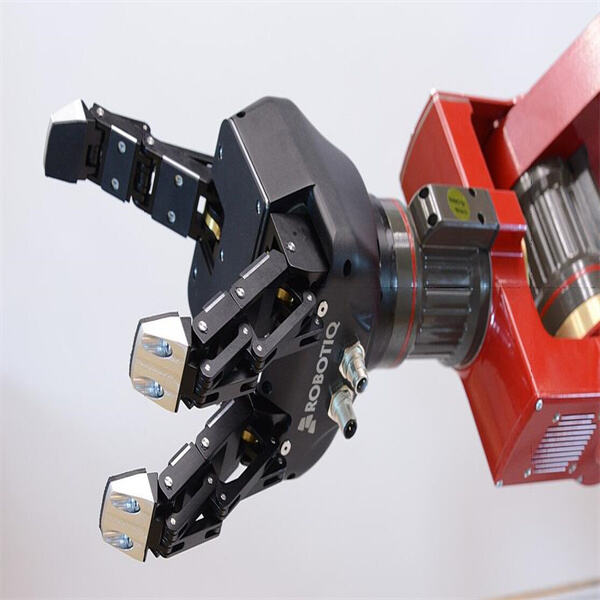

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

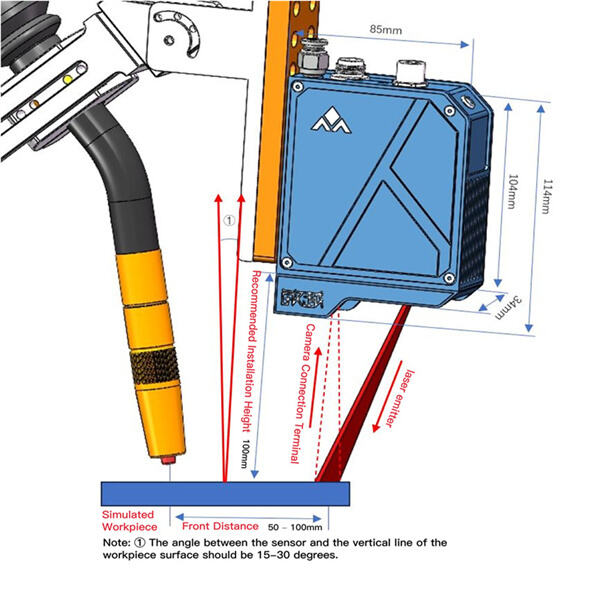

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.