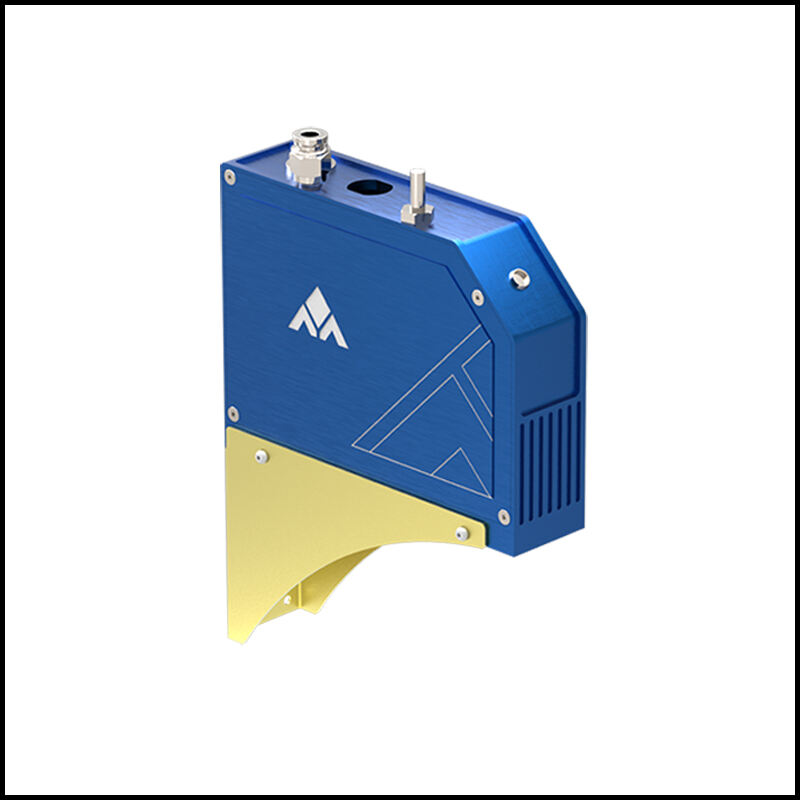

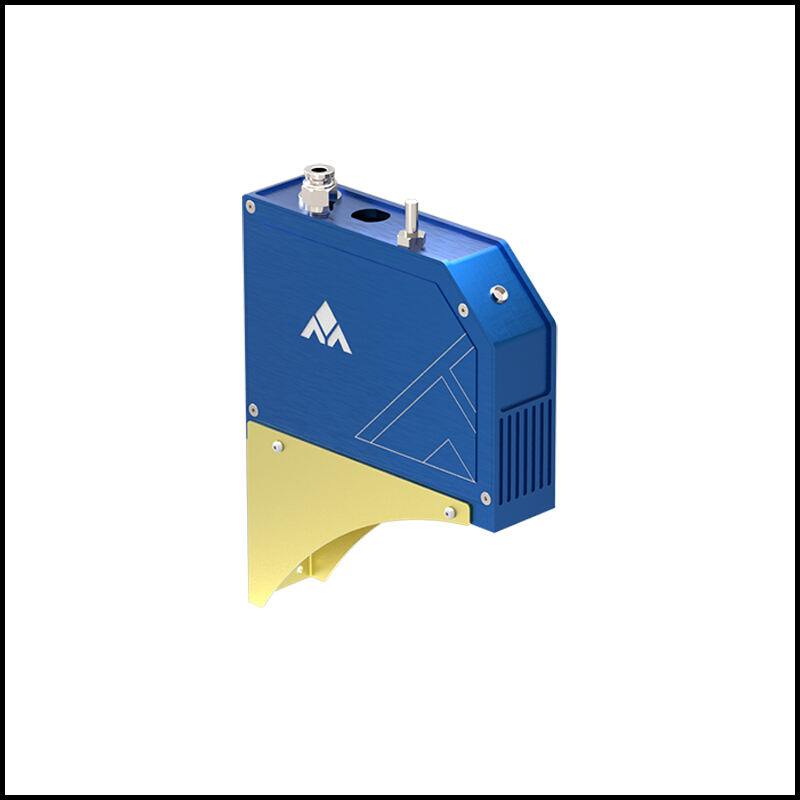

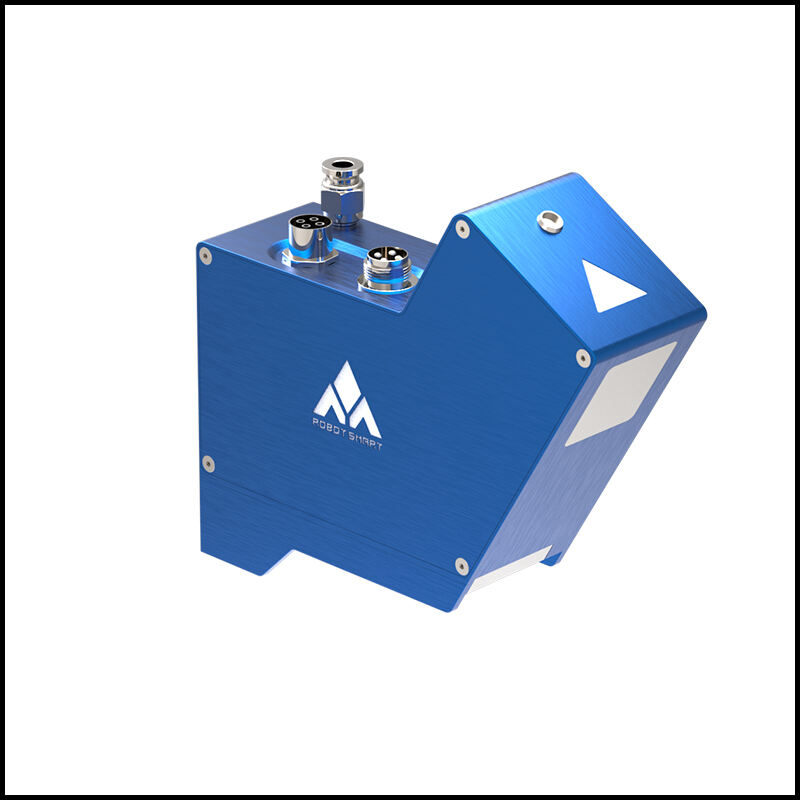

SmartVision 3D binocular vision camera

SmartVision 3D binocular structured light vision system

- Overview

SmartVision 3D binocular vision camera

Provide brain and eyes to robot.

Product Model

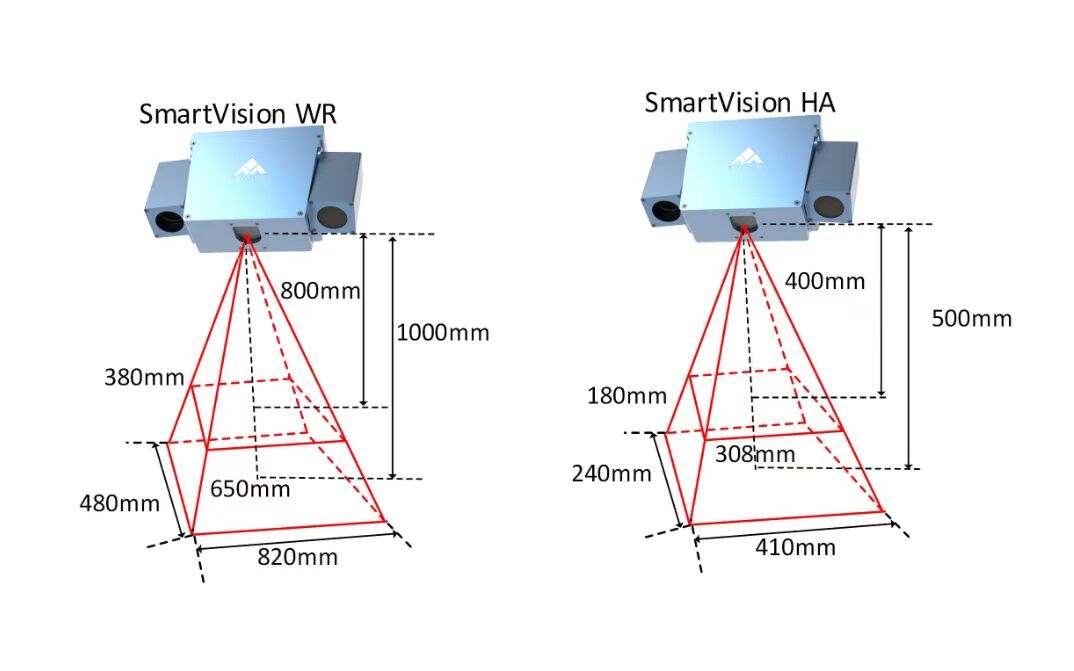

SmartVison series products are binocular structured light vision sensors developed by Minyue Technology for industrial robot welding and cutting applications. There are two models general SmartVison WR and high precision SmartVision HA depend on accuracy and range.

Main parameter

| PROJECT Number | Parameter | SmartVison WR |

| 1 | Operation distance(mm) | 800-1000 |

| 2 | Near field of vision (mm) | 650*380 |

| 3 | Far field of vision(mm) | 820*480 |

| 4 | Resolution (Pix) | 1624*1240 |

| 5 | Pixel (MP) | 2 |

| 6 | Measurement accuracy (mm) | 0.5 |

| 7 | Calibration accuracy (mm) | 0.03 |

| 8 | Collection time (s) | 1 |

| 9 | Overall size (mm) | 233*76*121 |

| 10 | Weight (kg) | 3 |

| 11 | Operating temperature range (℃) | 0~45º |

| 12 | Communication port | Gigabit Ethernet port |

| 13 | Operating voltage (V) | 12 |

| 14 | Protection grade | IP65 |

Product characteristics

1.It can output high-quality 3D data for a variety of metal workpiece, which can meet the diverse requirements of anti-environmental light, high precision, high speed and small volume in different requests.

2.Can be high precision, high speed, customizable, the field of vision can meet the actual needs of typical scenes.

3.It integrates 3D vision, deep learning, motion planning and other technologies, adopts graphics without programming which can carry out modular drag, wiring, parameter configuration and non-programming functions.

4.Adopt aluminum alloy material, fully enclosed shell, protection class is IP65, 24V operation voltage, it has passed CEFCCVCCI and RoHS certification. Can better cope with dust, vibration, moisture, electromagnetic interference and other harsh environment.

Minyue intelligent products

Laser seam tracking system

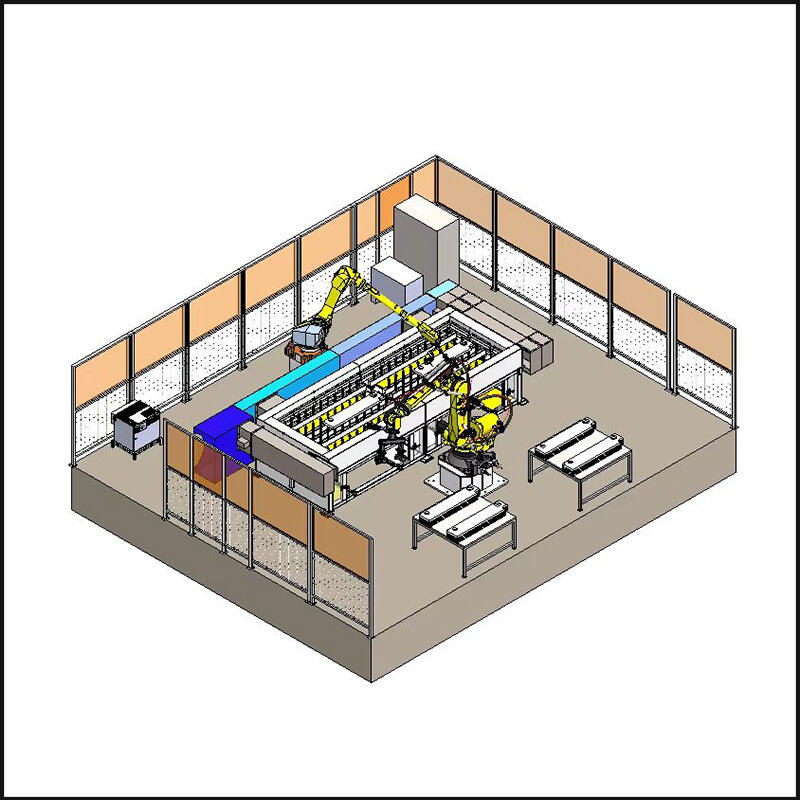

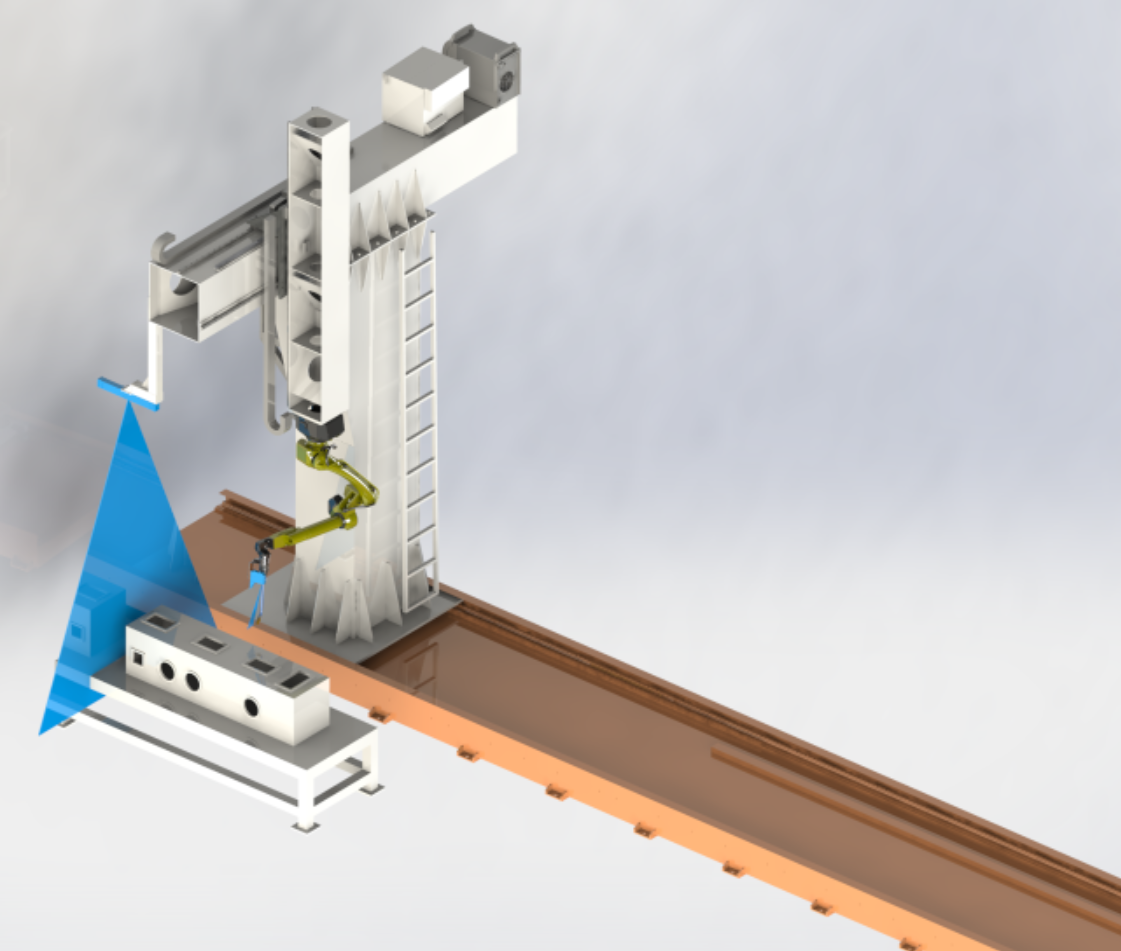

Many problems such as bad welding environment, high labor intensity, low welding efficiency and large processing error have been plaguing the industrial robot welding industry.Through SmartEye laser seam tracking system for identification and positioning,effectively solve the problem of poor consistency of workpiece, processing error, weld group gap irregular, reduce a lot of subsequent manual repair and grinding work, not only liberated the labor force, but also improve the work efficiency

Offline programming software

With the gradual release of the demand for multi-variety, small-batch and flexible production, the market has higher requirements for the convenience of robot programming, and the traditional teaching and reproducing robot has been unable to meet the market demand.Minyue off-line programming system -RobotSmart can quickly generate robot trajectory, effectively solve the programming problems such as complicated welding trajectory teaching, low programming efficiency and low robot utilization rate.

1.Minyue technology independently develops core laser seam tracking system and offline programming software products and combines them with applications

2.The combination of multiple independently developed products can quickly realize customers’ intelligent application requirements

3.Offline programming software quickly generate trajectory, vision to ensure trajectory accuracy, the combination of the two products to achieve "1+1" greater than 2

4.At present, our products have mature application in shipbuilding, carriage plate and other welding industries to help the intelligent upgrade of robotic welding and cutting manufacturing

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK