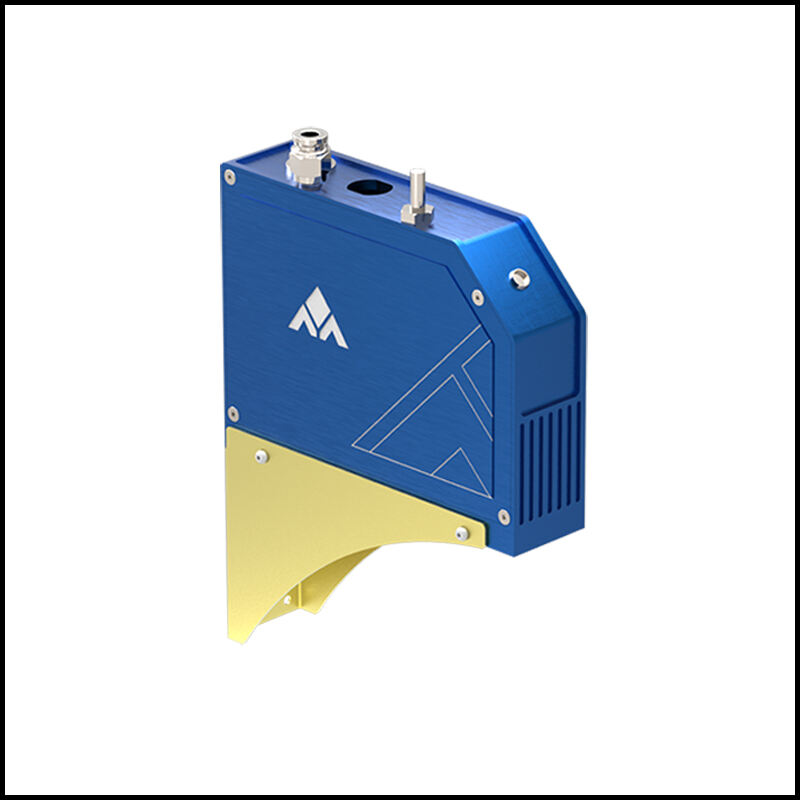

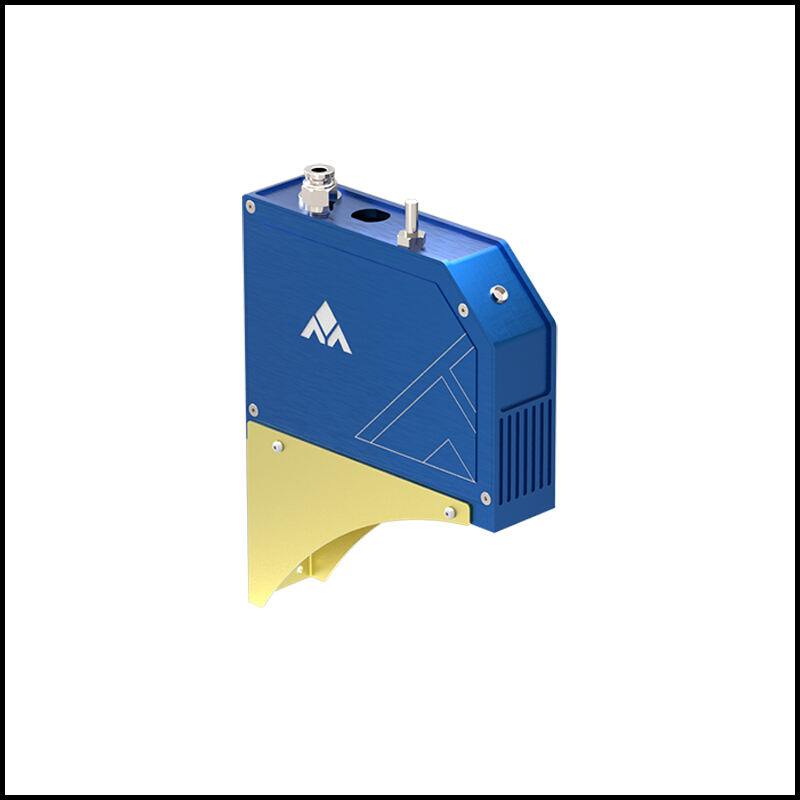

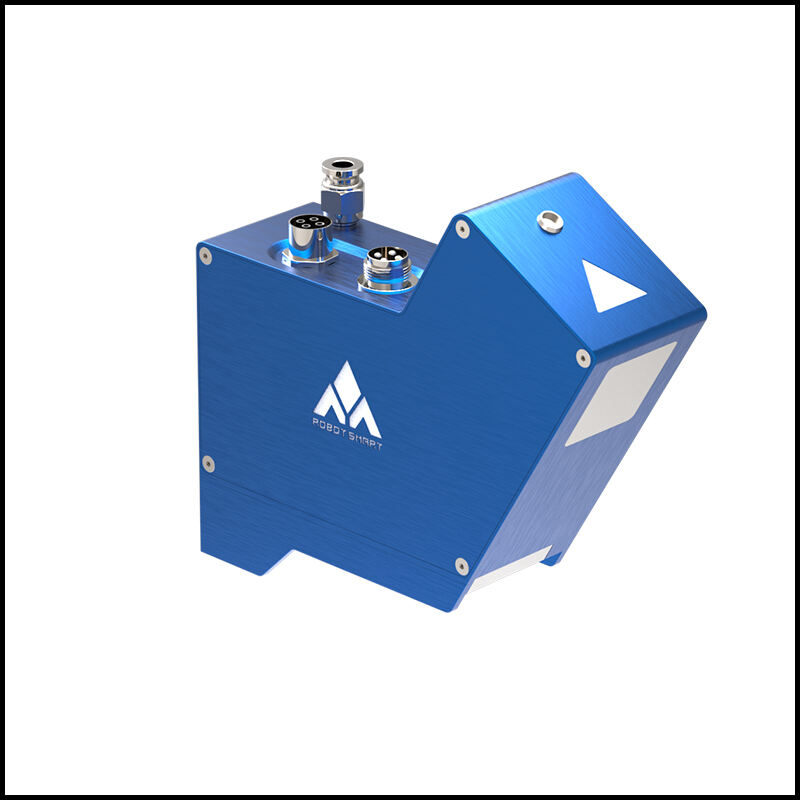

SmartVision 3D binocular visio photographica

SmartVision 3D binocular systema visionis lucis exstructa

- Overview

SmartVision 3D binocular visio photographica

Praebent cerebrum et oculos robot.

Model Product

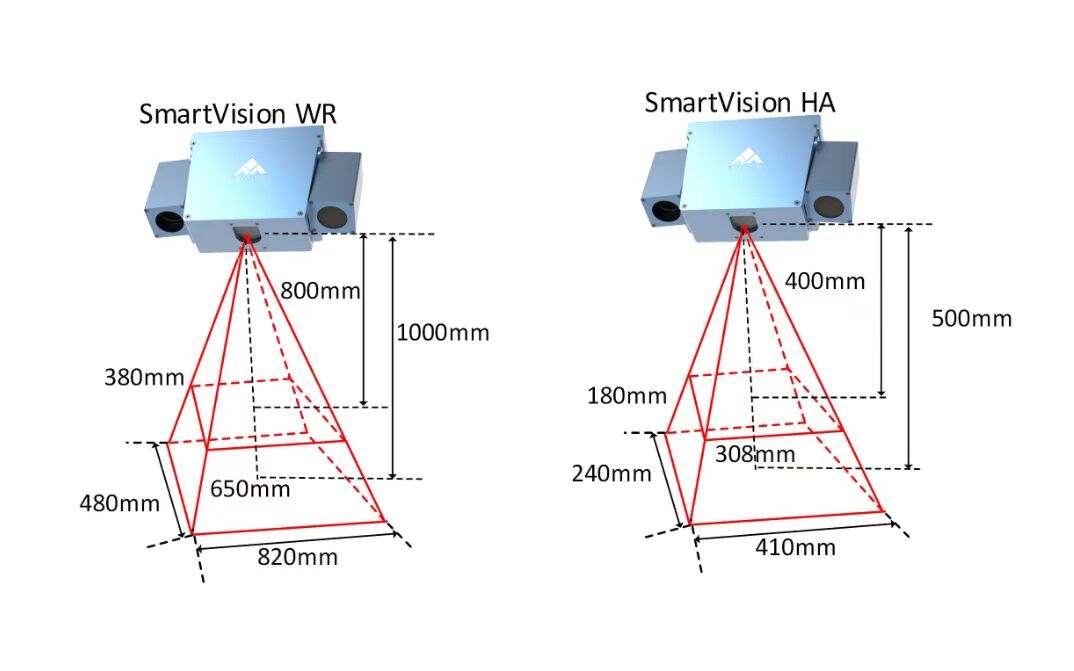

Series productorum SmartVison sunt binoculares sensores lucidi visi structi a Minyue Technologia elaborati pro applicationibus industrialis robot glutino et secantibus. Duo exemplaria generalia SmartVison WR et exquisita SmartVision HA a accuratione et extensione pendent.

pelagus parametri

| PROPOSITUM Number | Parameter | SmartVison WR |

| 1 | Operatio procul (mm) | 800-1000 |

| 2 | Prope campum visionis (mm) | 650*380 |

| 3 | Longe campus visionis(mm) | 820*480 |

| 4 | Consilium (Pix) | 1624*1240 |

| 5 | Pixel (MP) | 2 |

| 6 | Accuratio mensurae (mm) | 0.5 |

| 7 | Accuratio calibratiis (mm) | 0.03 |

| 8 | Collectio temporis (s) | 1 |

| 9 | Altiore magnitudine (mm) | * * 233 76 121 |

| 10 | Pondus (kg) | 3 |

| 11 | Operans temperatus range (℃) | 0~45º |

| 12 | portus communication | Aer ultra portum |

| 13 | Voltage operans (V) | 12 |

| 14 | gradus praesidio | IP65 |

productum characteres

1. Exponere potest summus qualitas 3D notitiarum pro varietate operis metallici, quae variis exigentiis lucis anti-environmentalis, altae subtilitatis, summae celeritatis et minoris voluminis in diversis petitionibus occurrere potest.

2. Potest esse subtilis, magna velocitas, customizabilis, campus visionis actualibus scaenarum typicarum necessitatibus occurrere.

3. Is visionem 3D, altam doctrinam, motum consiliorum aliarumque technologiarum integrat, graphics in programmate sine programmate quae modulari trahens, wiring, parametri conformationem ac functiones non programmandi explere potest.

4. Adopt aluminium mixturae materia, testa plene inclusa, classis tutelae IP65, 24V operatio intentionis est, CEFCCVCCI et RoHS certificatione transiit. Melius cum pulvere, vibratione, umore, electromagnetico impedimento et alia dura environment.

Minyue intelligentes products

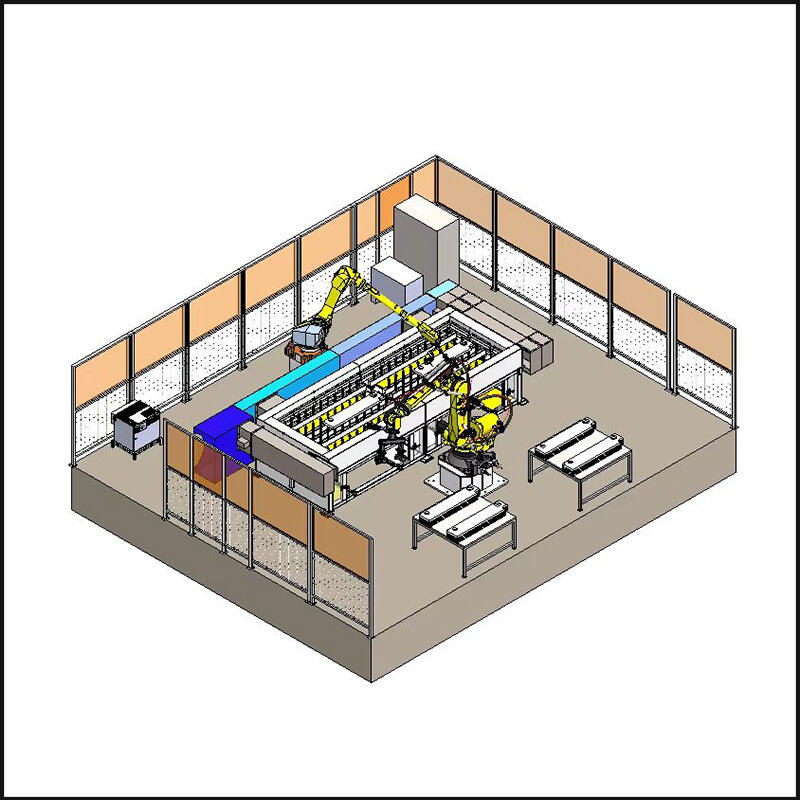

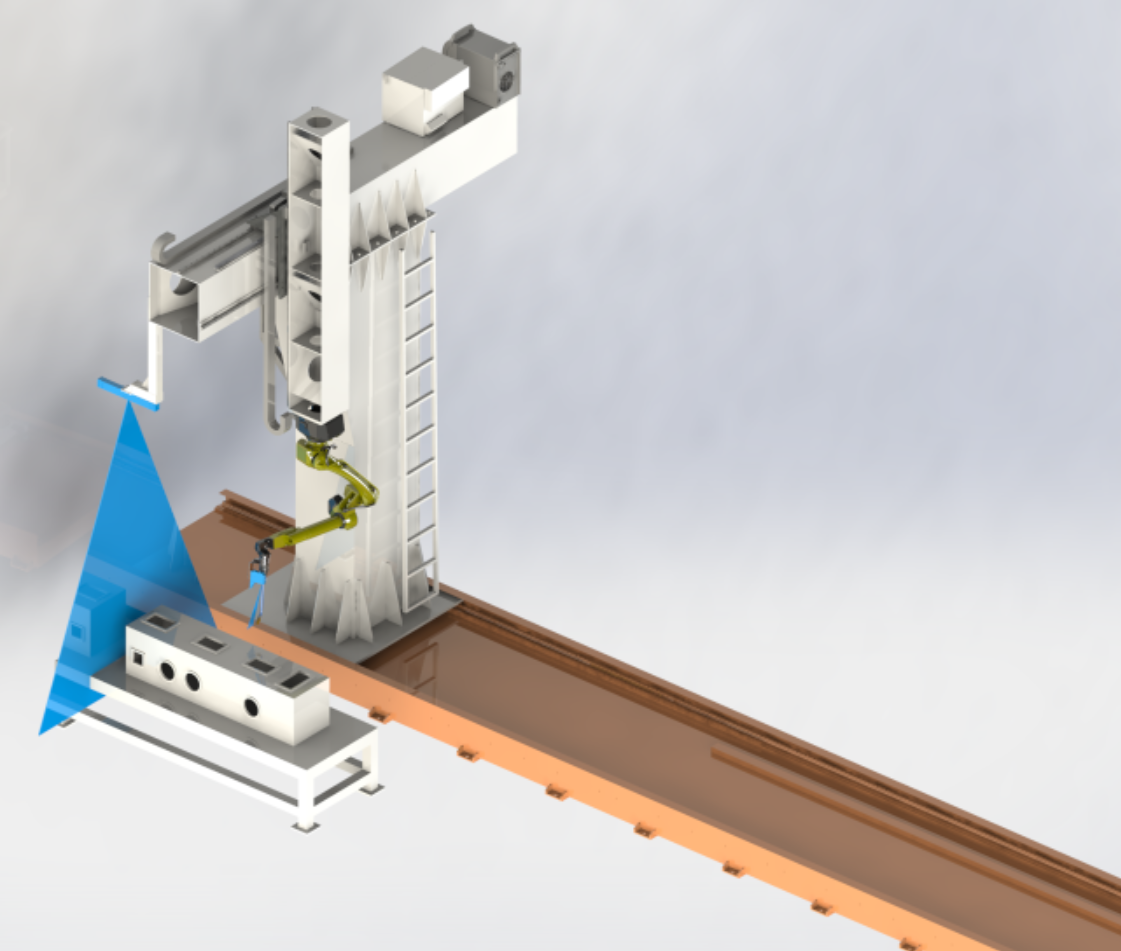

Laser summa tracking ratio

Multae difficultates sicut ambitus mali glutino, magni laboris intensio, humilis glutino efficientiae et magnae processus erroris industriae industriae industriae glutino homines percusserunt.Per SmartEye laser commissura tracking ratio ad identitatem et positionem,efficaciter solvendi problema constantiae pauperum operis operis, erroris processus, societatis hiatus irregularis pactionis, multum minuendum de reparatione manuali subsequentium et de opere moliendo, non solum vim laboris liberavit, sed etiam efficaciam laboris emendavit.

Online programming software

Cum gradatim emissio postulationis multi- varietatis, parvae massae et flexibilis productionis, mercatus altiora requisita ad programmandi roboti commodum habet, ac institutio traditionis ac reproductionis roboti mercatus postulatio occurrere non potuit.Minyue off-linea programming system -RobotSmart celeriter generare potest trajectoriam robotam, efficaciter solvendi problemata programmandi sicut perplexa doctrina trajectoria conglutinatio, efficientia humilis programmatio et humilis rate utendo robot.

1.Minyue technology independenter auget nucleum laser commissurae ratio tracking et programmatio programmandi programmatum programmatum cum applicationibus componit

2. Coniunctio multiplex sine elaboratis productis intellegi potest celeriter clientium applicationis intelligentium requisita

3.Offline programmatio programmatio celeriter generabit trajectoriam, visionem ut accurationem trajectoriam curet, coniunctio duorum productorum ad "1+1" major quam 2

4. In praesenti, fructus nostri maturam applicationem habent in fabricando, vecturando et aliis industriae glutinis ad adiuvandum intelligentes upgrade glutinis robotici et fabricandi secandum.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK