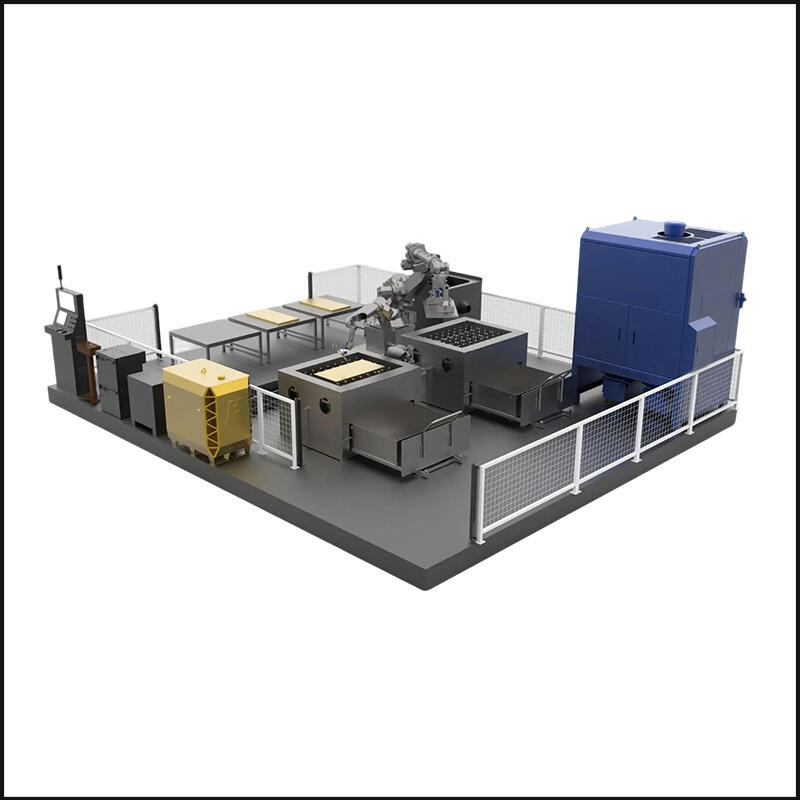

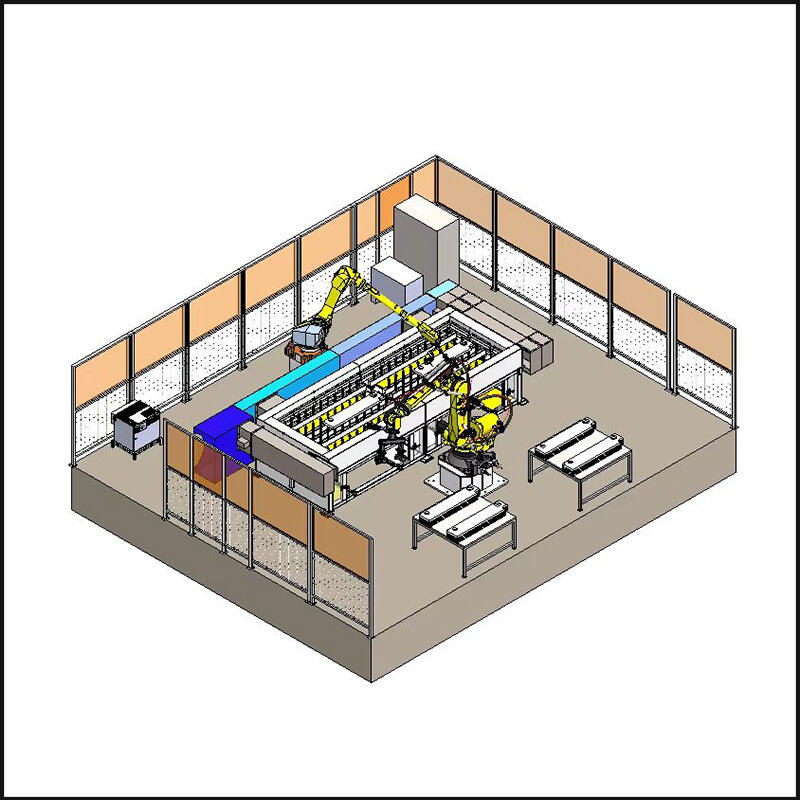

Solutiones incisionis obliquae cum duobus machinis, duobus robotis et duabus tabulis sine programma

- Conspectus

Solutiones incisionis obliquae cum duobus machinis, duobus robotis et duabus tabulis sine programma

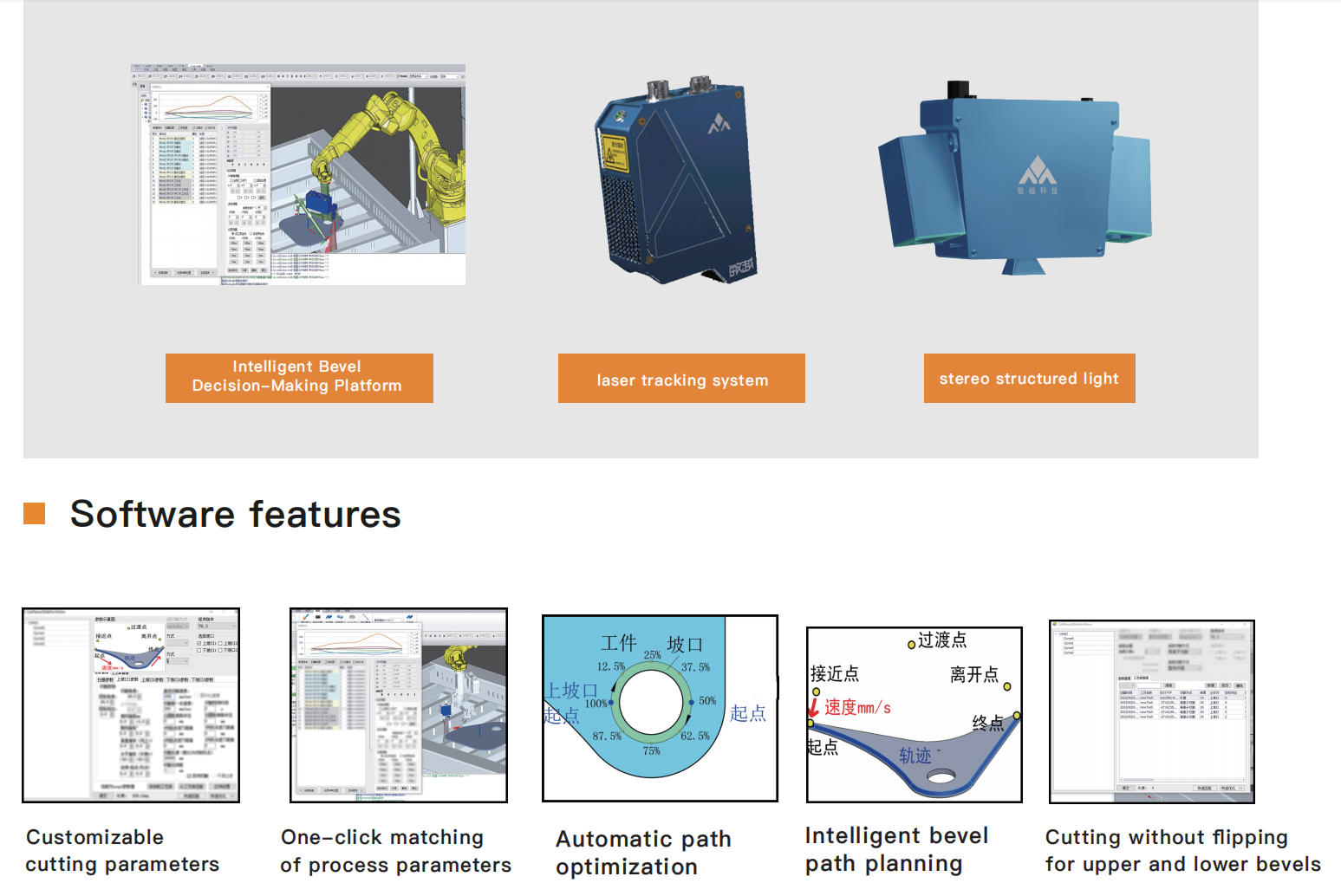

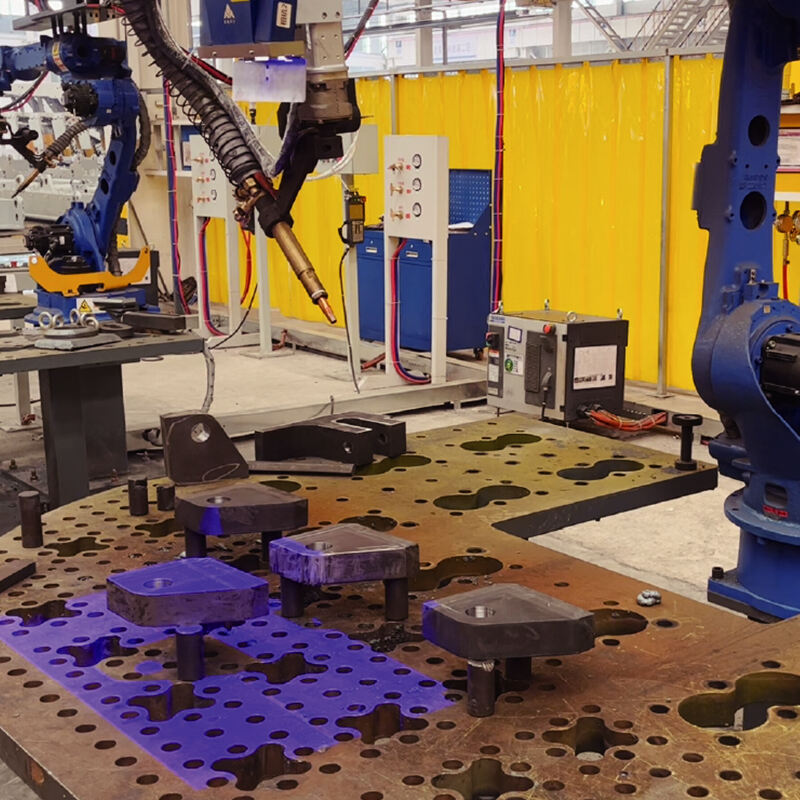

SmartCut intelligent oblique cutting workstation utitur MinYue's annis expertus in CAD/CAM, robotica, 3D visio, et artificialis intelligentia. Aedificatum super MinYue’s sponte-developed intelligent decision-making system RobotSmart et 3D vision sensors, introducit model-driven et vision sensor-based sine doctrina automatic programming method, enabling autonomous robotic cutting. Haec technologia tractat varias quaestiones in traditional industrial robot oblique cutting. Completa system constat ex industrial robotic brachium, binocular structured light vision sensors, industrial controller (integrated cum RobotSmart intelligent cutting software), et cutting accessories.

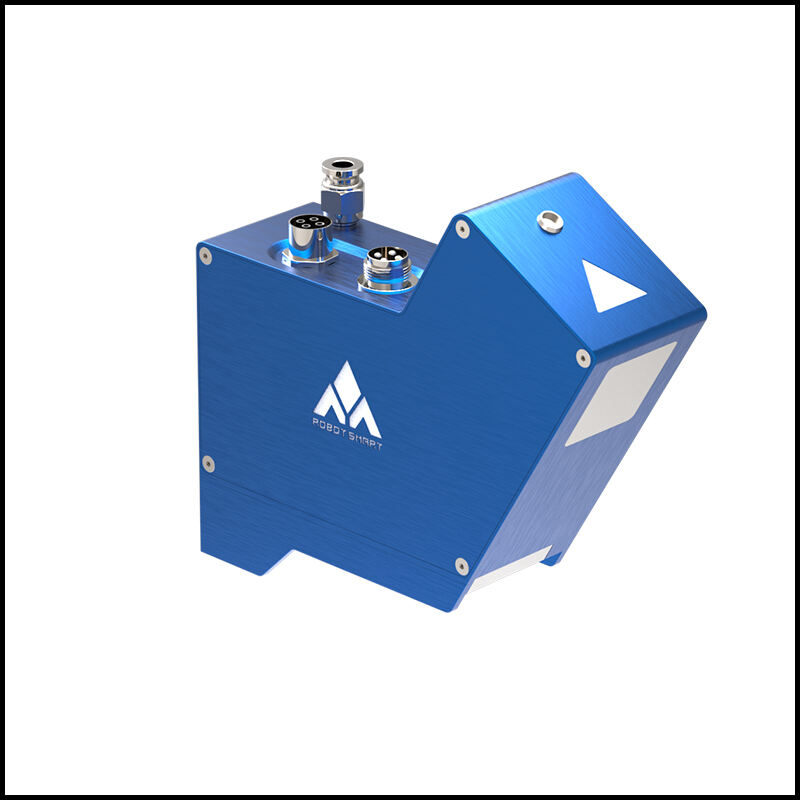

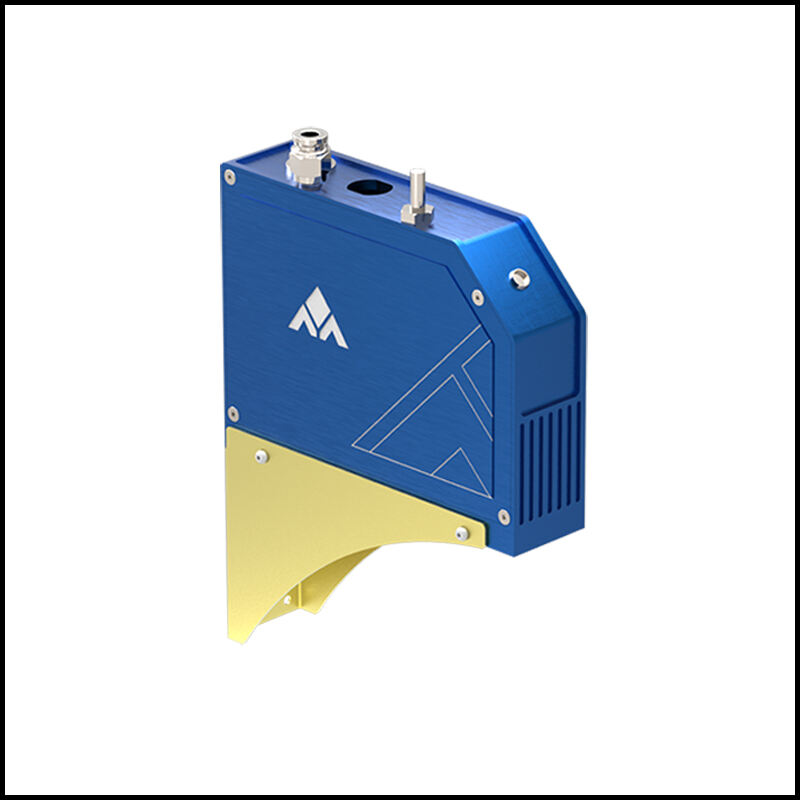

Camera binoculorum visionis 3D SmartVision

Provide cerebrum et oculos roboti.

Productum Model

Producti series SmartVison sunt binoculares visus sensores lumine structurato, quos Minyue Technologia pro applicationibus roboticae industrialis in conflatu et sectura fabricavit. Sunt duo modela: generale SmartVison WR et altissima praecisio SmartVision HA, quae differunt secundum exactitudinem et ambitum.

Camera visionis 3D cum ampliore prospectu utendo lineari laser ad positionem iuvandam, per systema binoculare stereoscopicum adsciscens tres dimensiones spatii objecti.

Scansio 3D altae praecisionis contornorum objecti quam inversa modeling, et comparatio eius ad modelum standard 3D, realisatio positionis, defectuum detegendorum, mensurationis dimensionum, objecti tenendi aliarumque functionum applicationum.

Habet praestantia singularia in rapidis detectionibus sceneriorum motus celeris, contra fulgorem, contra reflexionem, et applicando in scenis indoor et outdoor.

Caracteres principales::

1. Resistentia ad lucem fortem, anti-reflexio, apta varietati complexarum circumstantiarum.

2. Alta praecisio, altus framen ratio, et data administratio rara.

3. Intellectus machinae ad faciliorem implementationem.

4. Varia optio ad necessitates diversarum schematium respondendum.

5. Magnus profunda campi, magnus campus visionis, ad varias applicationes camporum visionis satisfaciendum.

6. Celer calibratio et flexibilitas.

| Exemplum | My-Laser -1920x1600 | My-Laser-1920x2600 |

| Distantia pupillae camarae | 320mm | 620mm |

| Dimensio ( L x W x H ) | 390x90x64mm | 690x90x64mm |

| Pondus | 1800g | 2600g |

| distantia operativa photographica | 600-2000mm | 1500-3000mm |

| campus visionis | 400x800mm | 1200x2100mm |

| campus visionis extrema | 1500x2800mm | 2500x4200 |

| Resolutio axis X | 0.24 | 0.88 |

| Resolutio axis Y | 0.46 | 1.14 |

| Resolutio axis Z | 0.17 | 0.56 |

| Resolutio cartae profundi | 2048x1536 | |

| Maximus celeritas framen | 3000Lineae/S | |

| Contrarius luce ambientali | 480000 LUX | |

| Interfacing externa | Porta Ethernet Gigabit | |

| Modus communicationis | Invocatio functionis SDK/Modbus TCP | |

| Laser Type | Lumen caeruleum (450nm) Lumen rubrum (850nm, 940nm) | |

| Voltius/Potentia | 24V/30W | |

| Temperatura operativa | -20℃---70℃ | |

| IP level | IP65 | IP 65 |

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK