産業用ロボットのオフラインプログラミングシミュレーションプラットフォーム

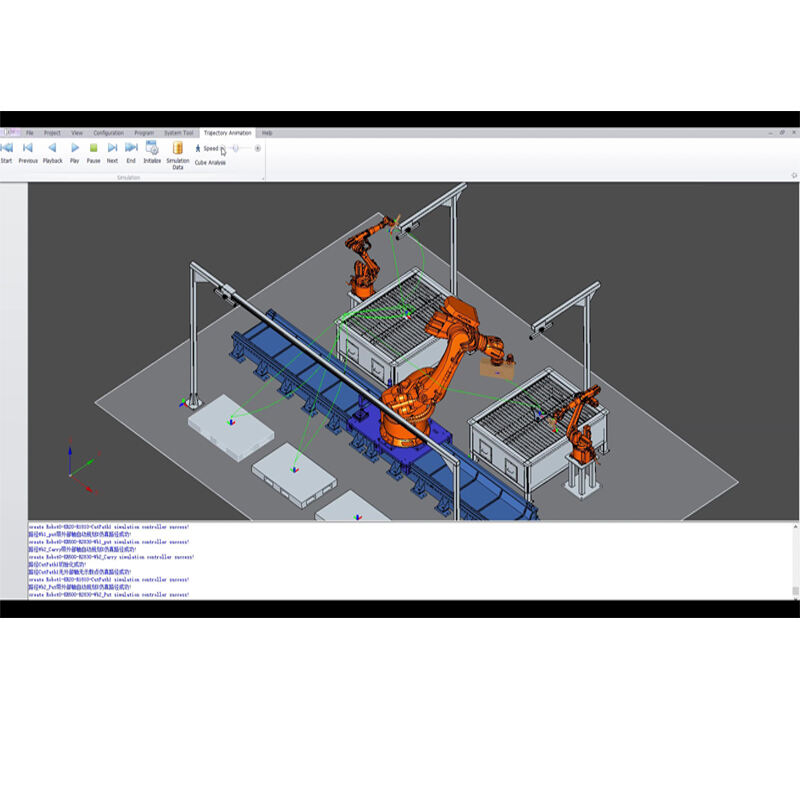

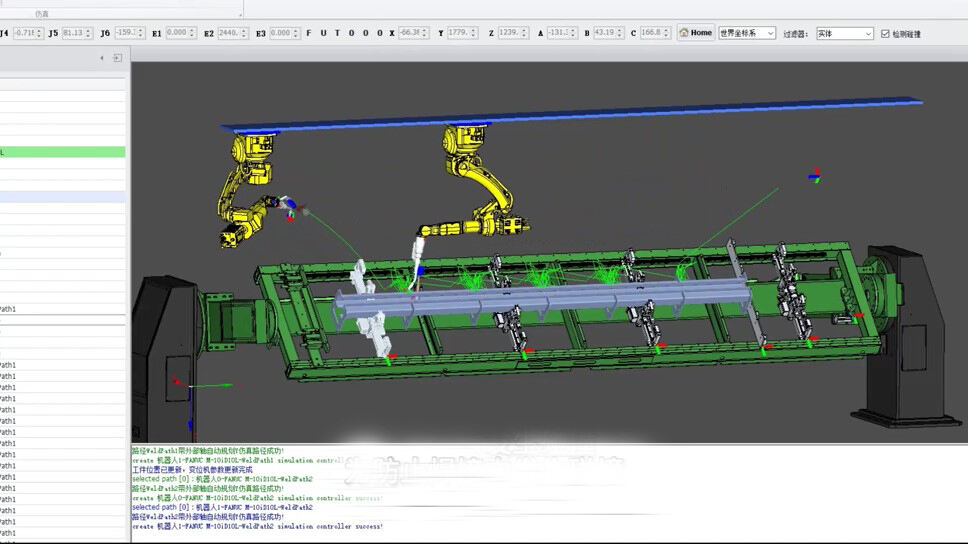

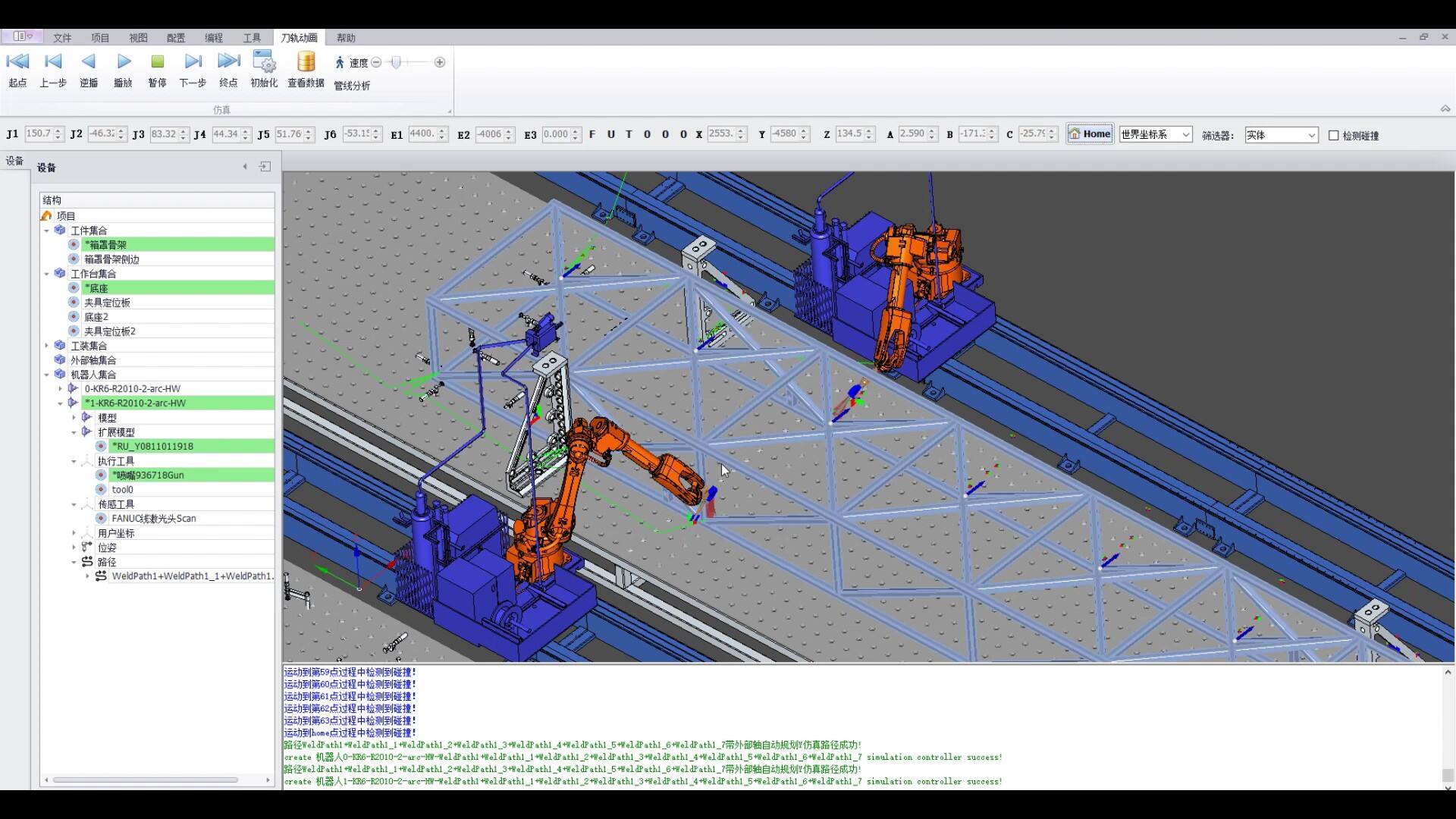

ロボットの動作コードを自動生成し、複数のロボット、複数の外部軸、ポジショナーを協調させることができます。最大24軸の軌道を計画可能です。ロボットの動作シミュレーション、衝突検出、特異点回避、軸制限検出を実現します。

- 概要

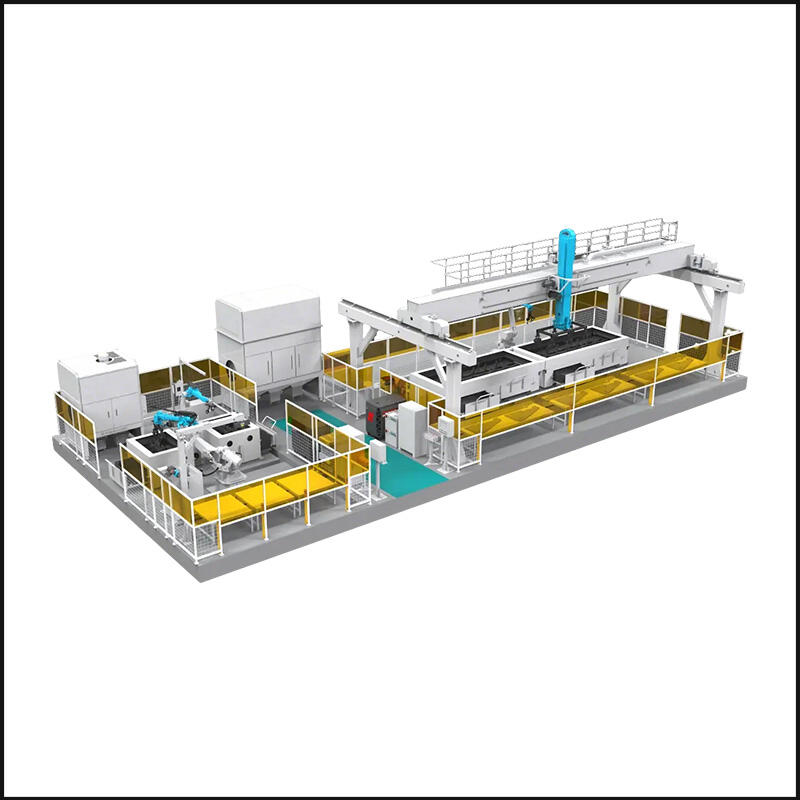

MINYUEテクノロジーの非教育型インテリジェント溶接制御システムは、長年の経験を基にロボット溶接自動化分野に従事しています。業界の課題解決を目指し、溶接技術者の不足の増加、部品の荷下ろしや組み立ての精度不足、鋼構造物、造船、重工業、製造業などにおける大量の非標準かつ少量の作業部品の需要に対応するため、完全統合と教師不要の利点を持つインテリジェントな溶接ソリューションを提供します。

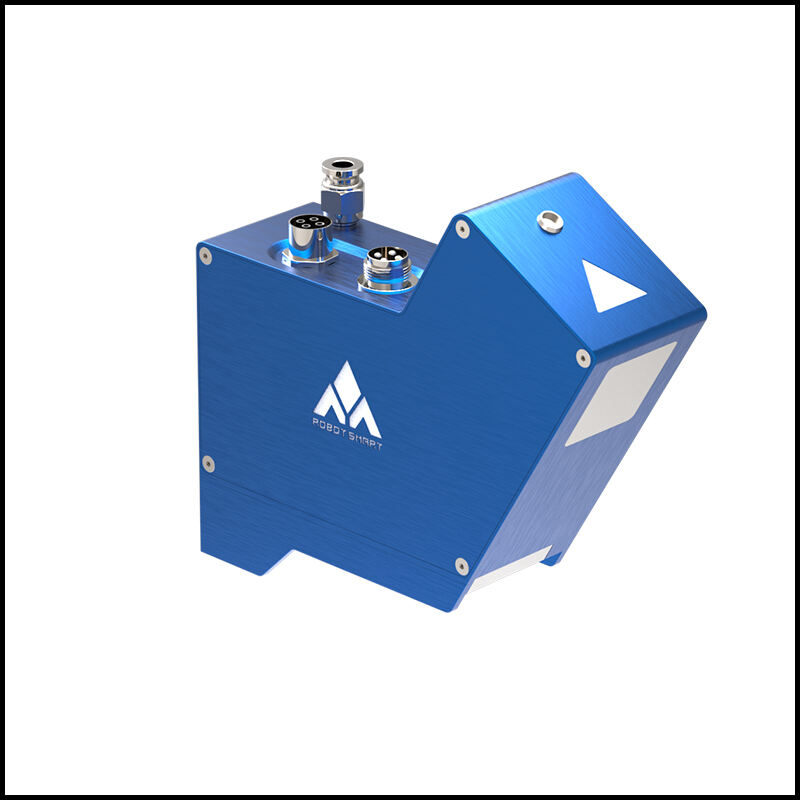

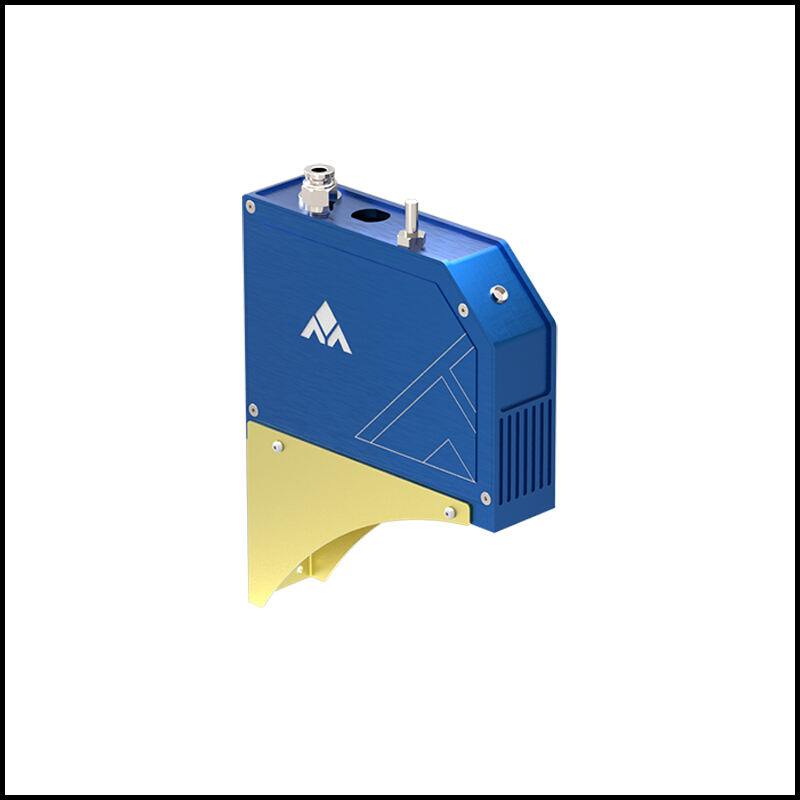

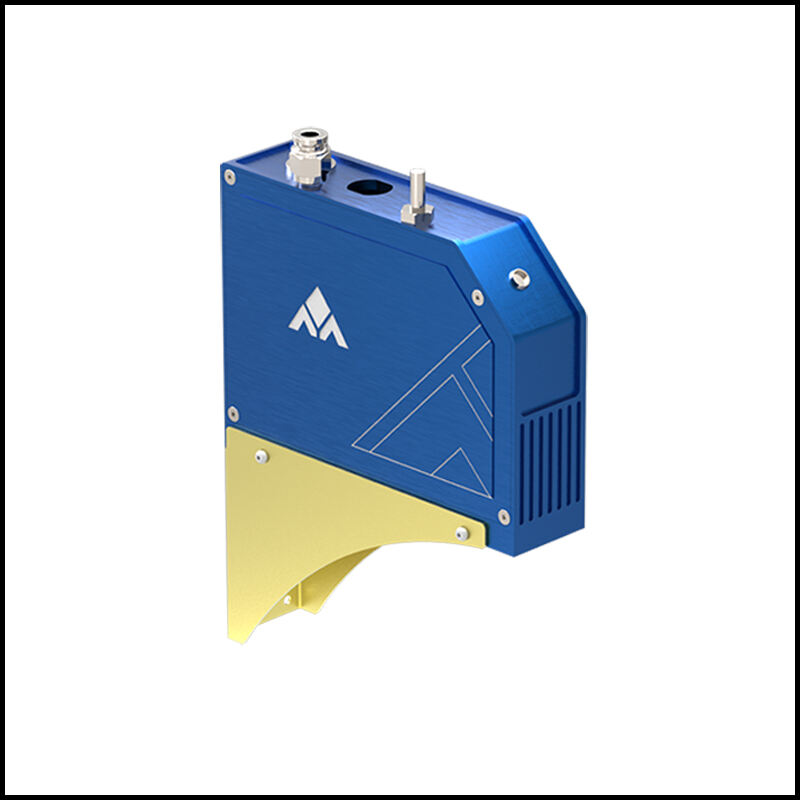

ロボットスマートは、岷越のインテリジェントな意思決定システムで、迅速にロボットの軌道を生成でき、複雑な溶接軌道の教示、低编程効率、ロボットの低利用率などの現場でのプログラミング問題を効果的に解決します。

ロボットスマート インテリジェント デcisionシステムでは、ソフトウェアに部品の3Dデジタルモデルをインポートし、3Dモデル上の点、線、面を選択することで溶接軌道のポイントとその位置を生成し、ロボット側で直接使用可能なロボットプログラム、視覚定位用のポイントクラウドモデル、作成したユーザ座標系も生成します。

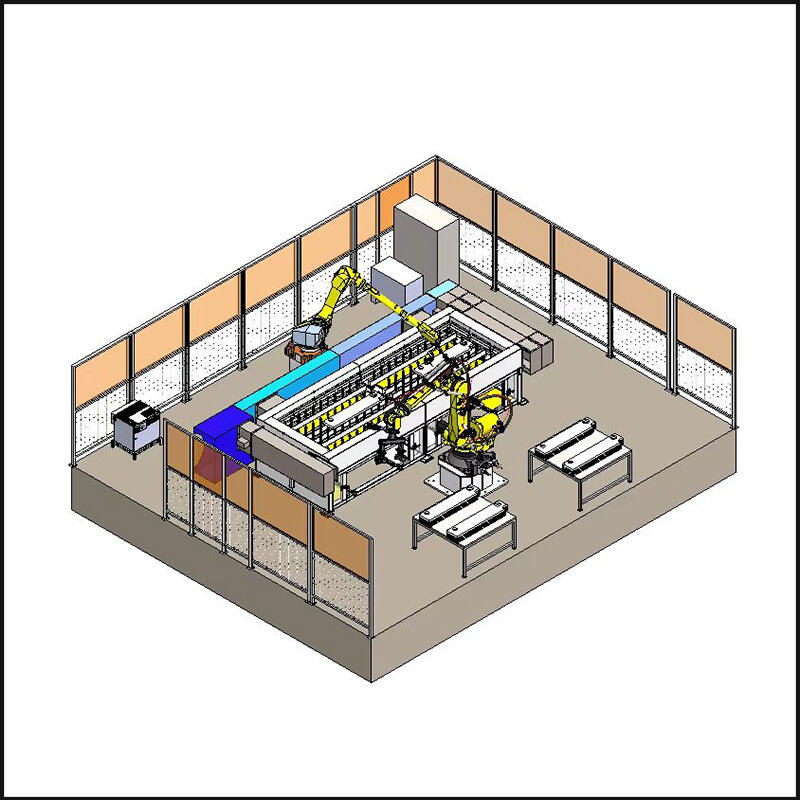

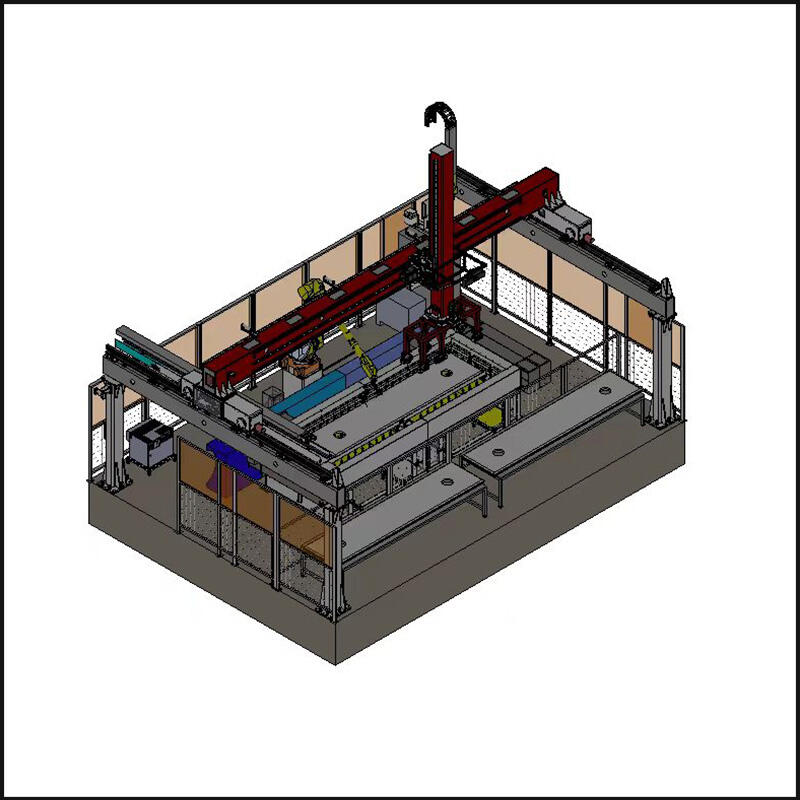

このロボット用のオフラインプログラミングソフトウェアは、ロボット、ワークセル、生産ラインのモデリングとシミュレーション、および衝突検出を可能にします。また、運動学、力学、軌道計画、軌道最適化などといった一般的なロボットアルゴリズムパッケージを統合しています。オフラインプログラミングソフトウェアのシミュレーションでは、実際のコントローラーと同じ時間同期と軌道動作効果を実現し、真のオフラインプログラミングを実現します。プログラミング結果は異なるロボットコマンド言語で生成でき、実際のコントローラーにダウンロードして動作させることができます。

主な特徴

モジュール性による統合: ソフトウェアはモジュール化されており、顧客の異なるニーズに応じてカスタマイズできます。

衝突検出と距離計算: シミュレーションモデルの最小距離の計算や衝突の有無を迅速に実現します。

衝突検出と距離計算: シミュレーションモデルの最小距離の計算や衝突の有無を迅速に実現します。

順運動学と逆運動学: 並列機構および直列機構の順運動学と逆運動学の汎用アルゴリズムをサポートしています。

ダイナミクス:シリーズ並列メカニズムを実装するための汎用ダイナミクスアルゴリズム。

軌道計画アルゴリズム:ロボットの衝突のない軌道を自動で計画できます。

軌道最適化アルゴリズム:時間とエネルギーを最小限に抑えてオフラインでロボットの軌道を最適化します。

仮想コントローラー:仮想コントローラーは精密な時間と軌道制御を実現し、シミュレーション効果は実際のコントローラーと同じです。

複数のポジショナー、複数の外部軸をサポート。

さまざまなシミュレーションシナリオを柔軟に構築可能。

組み込み済みのロボットモデルは100以上あり、四大ロボットメーカーおよび国内主要ブランドの全モデルに対応しています。

ロボット通信のデバッグには1〜2日しかかかりません。デバッグ周期が短く、デバッグコストも低くなっています。

三次元デジタルモデル

準備完了 - ダウンタイムなしでオフラインプログラミングが可能です。次の日/週/月の生産プログラムを事前にMesスケジューリング計画に合わせて作成できます。

効率的、ノンティーチング、パラメトリック、グラフィカルプログラミングで30分以内に自動プログラム生成が可能となり、使用のハードルを低減します。

賢明な - 定期的にレポートを生成し、例外を提醒する。部品ライブラリ、パラメータライブラリ、プロジェクトライブラリのデータをリアルタイムで更新および管理します。

ロボットの動作コードを自動生成し、複数のロボット、複数の外部軸、ポジショナーを一緒に動作させることができます。最大24軸の軌道を計画できます。

ロボットの動作シミュレーション、衝突検出、特異点回避、軸制限検出を実現します。

衝突検出、特異点回避、作業範囲到達可能性検出を行います。シミュレーションチェックを行い、衝突、特異点、過旅行、到達不能に対するワンクリックソリューションを提供します。

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK