Piattaforma di simulazione per la programmazione offline dei robot industriali

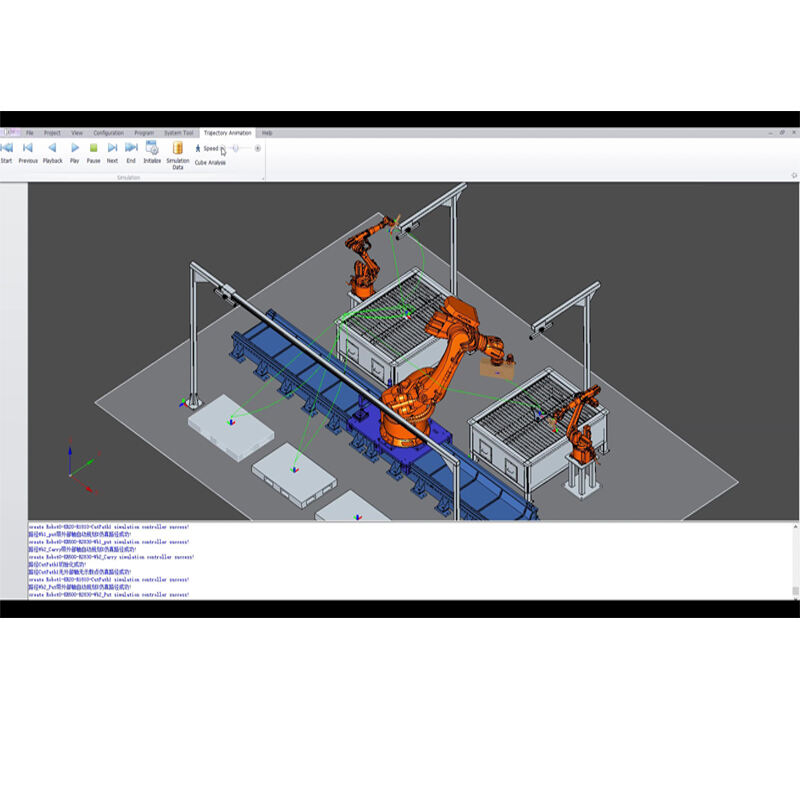

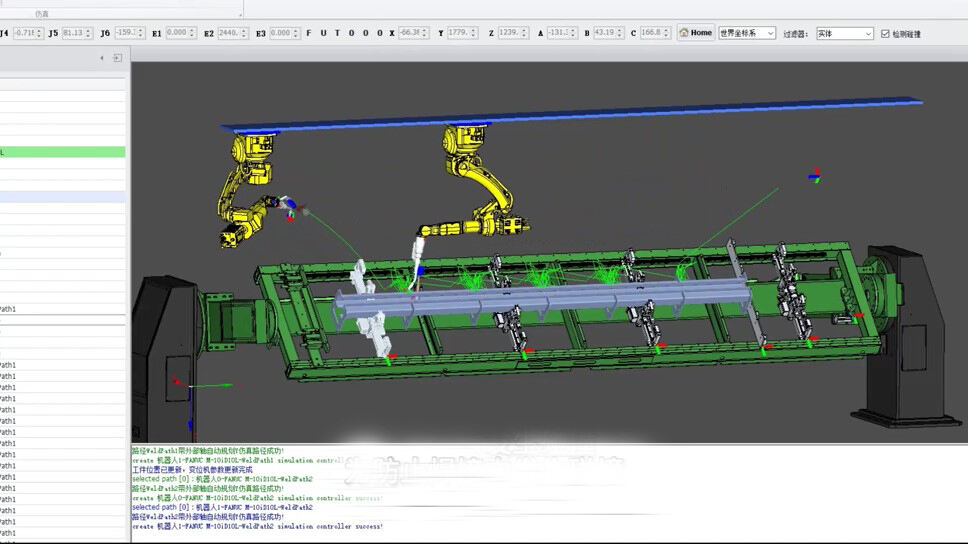

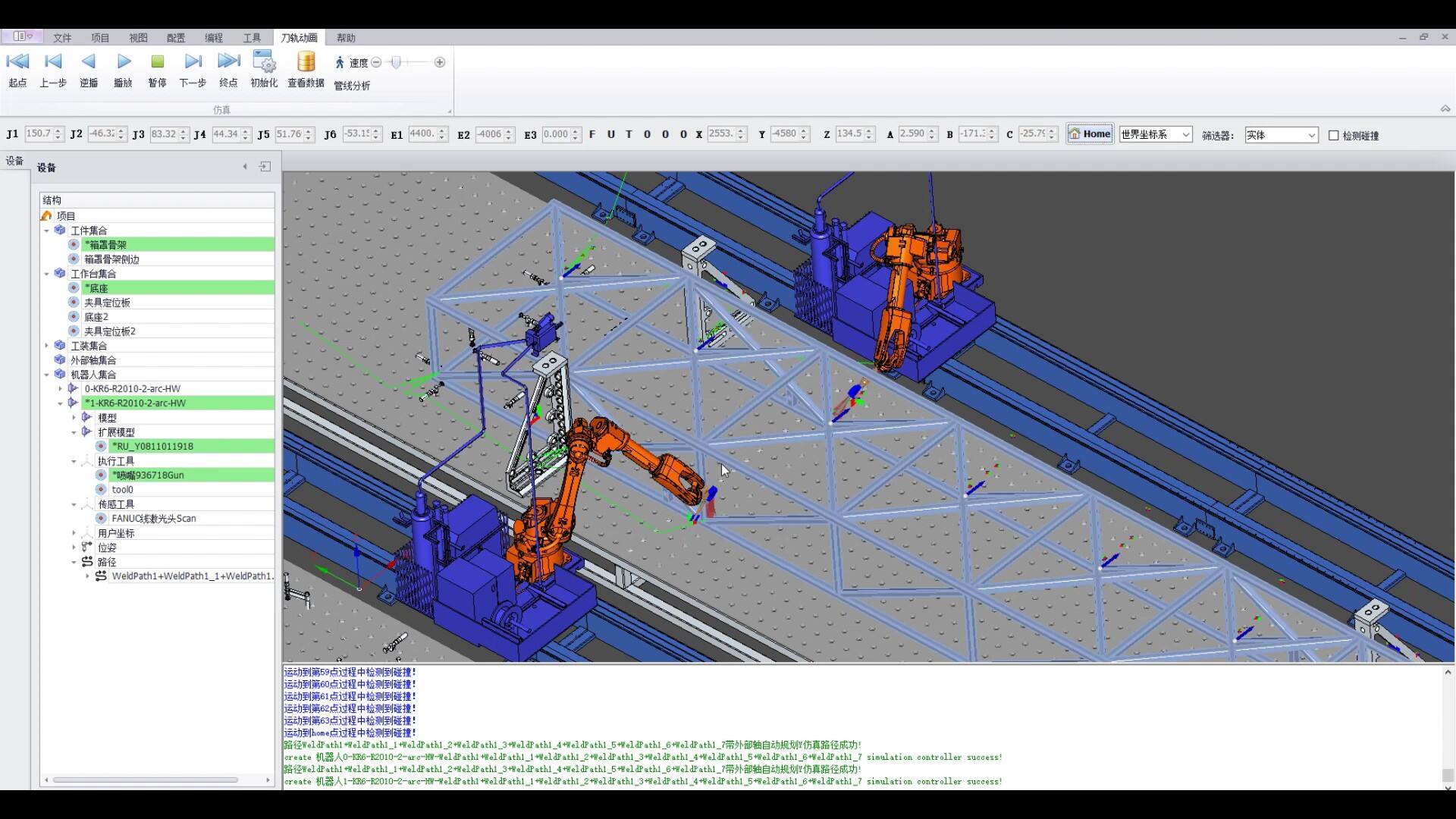

Generazione automatica del codice di movimento del robot, con più robot, più assi esterni, posizionatore, che lavorano insieme. È possibile pianificare una traiettoria massima di 24 assi. Realizza la simulazione del movimento del robot, la rilevazione di collisioni, l'evitamento di singolarità e la rilevazione dei limiti degli assi.

- Panoramica

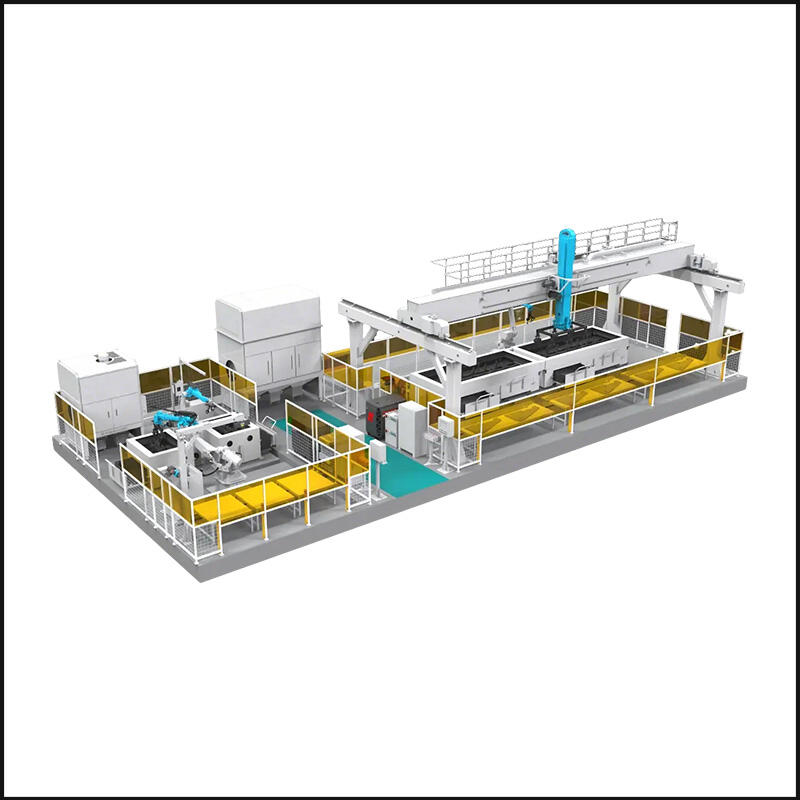

Il sistema di controllo intelligente per il welding non-insegnante di MINYUE Technology si è occupato del campo dell'automazione del welding robotico con anni di esperienza. Per risolvere i punti critici dell'industria, come la crescente carenza di saldatori, precisione insufficiente nel caricamento e assemblaggio dei pezzi, e una grande quantità di componenti non standardizzati e in piccole serie necessari nella costruzione metallica, costruzione navale, industria pesante, manifatturiera, ecc. Offre una soluzione intelligente per il welding caratterizzata da vantaggi di integrazione totale e assenza di insegnamento.

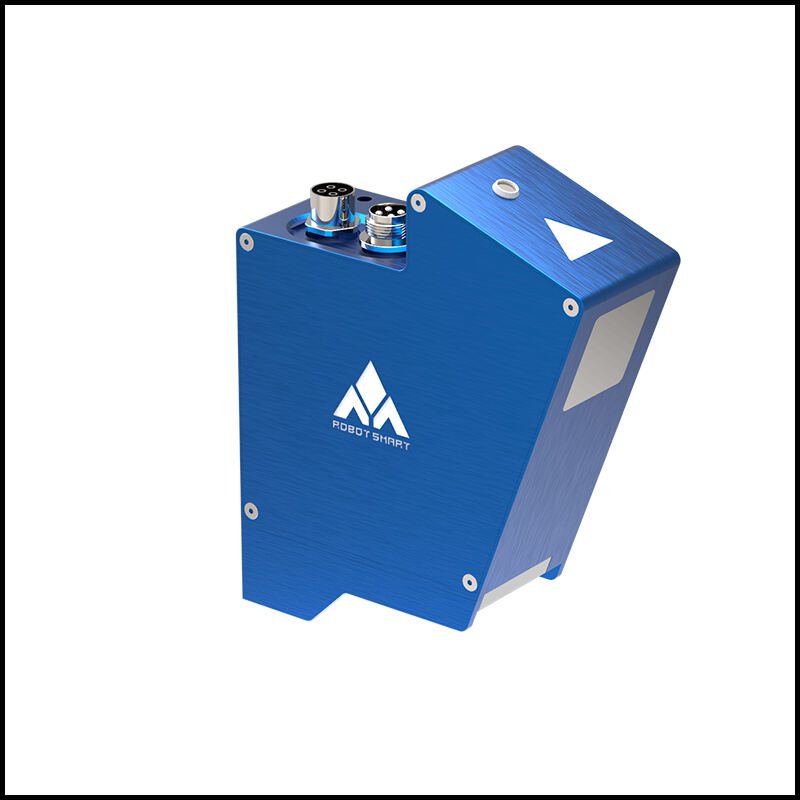

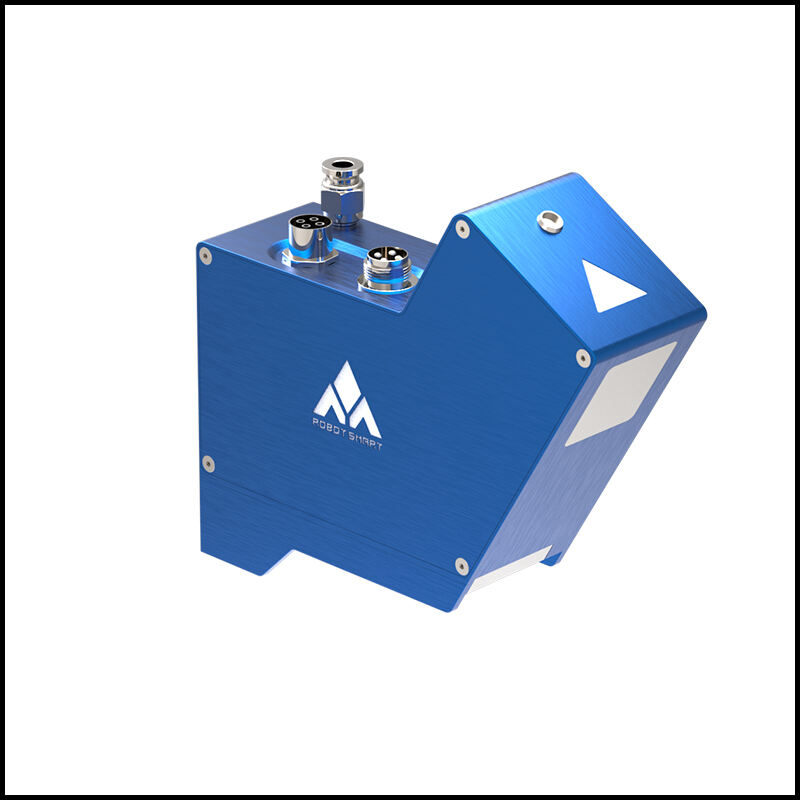

RobotSmart, il sistema di decisione intelligente di MinYue, può generare rapidamente traiettorie per robot, risolvendo efficacemente i problemi legati all'insegnamento di traiettorie complesse per la saldatura, alla bassa efficienza di programmazione, al basso utilizzo dei robot e ad altri problemi di programmazione sul campo.

Il Sistema di Decisione Intelligente Robotsmart genera i punti della traiettoria di saldatura e le loro posizioni importando il modello 3D del pezzo nel software e selezionando i punti, le linee e le superfici sul modello 3D, nonché generando un programma per robot utilizzabile direttamente sul lato robot, un modello di nube di punti per la localizzazione visiva e il sistema di coordinate utente creato.

Questo software di programmazione offline per robot consente la modellazione e la simulazione di robot, Workcells e linee di produzione, nonché il rilevamento di collisioni. Integra pacchetti algoritmici comuni per robot, inclusi cinematica, dinamica, pianificazione del percorso, ottimizzazione del percorso e altro. La simulazione del software di programmazione offline può raggiungere la stessa sincronizzazione temporale ed effetto di esecuzione del percorso del controller reale, realizzando una vera programmazione offline. I risultati della programmazione possono essere generati in diversi linguaggi di comando dei robot e scaricati sul controller reale per l'operazione.

Principali Caratteristiche

Modularità integrabile: il software è modularizzato per soddisfare le diverse esigenze dei clienti.

Rilevamento di collisioni e calcolo delle distanze: si realizza rapidamente il calcolo della minima distanza del modello di simulazione e se ci sia o meno una collisione.

Rilevamento di collisioni e calcolo delle distanze: si realizza rapidamente il calcolo della minima distanza del modello di simulazione e se ci sia o meno una collisione.

Cinematica diretta e inversa: Supporta algoritmi generalizzati per la cinematica diretta e inversa dei meccanismi serie-parallelo.

Dinamica: algoritmi di dinamica generalizzata per l'implementazione di meccanismi serie-parallelo.

Algoritmo di pianificazione delle traiettorie: può pianificare automaticamente traiettorie robotiche senza collisioni.

Algoritmo di ottimizzazione delle traiettorie: minimizza tempo ed energia offline per ottimizzare la traiettoria del robot.

Controllore Virtuale: il controllore virtuale realizza un controllo preciso del tempo e della traiettoria, e l'effetto della simulazione è identico a quello del controllore reale.

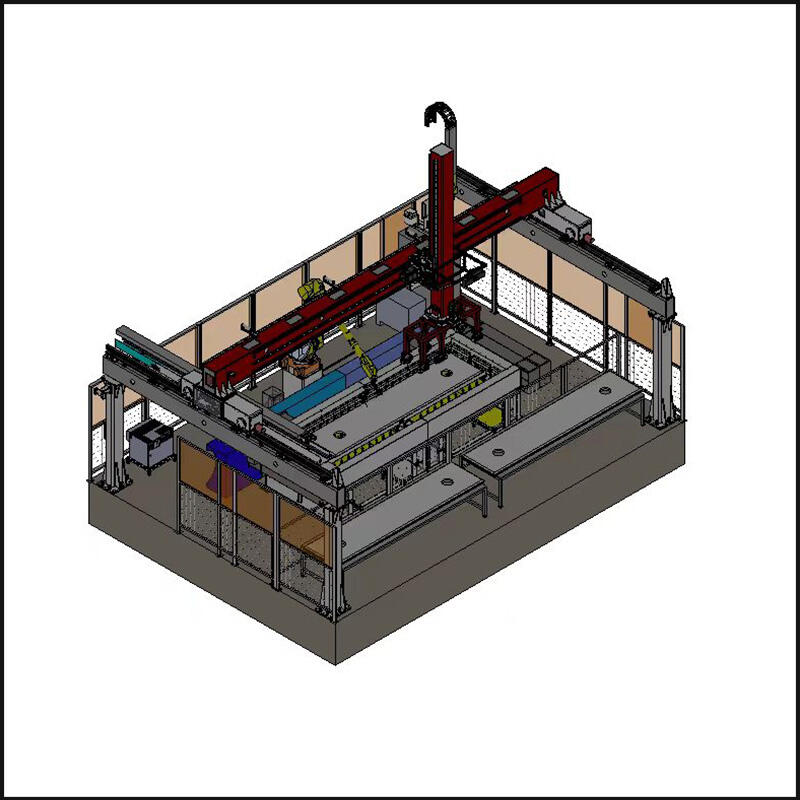

Supporta più posizionatori, molteplici assi esterni.

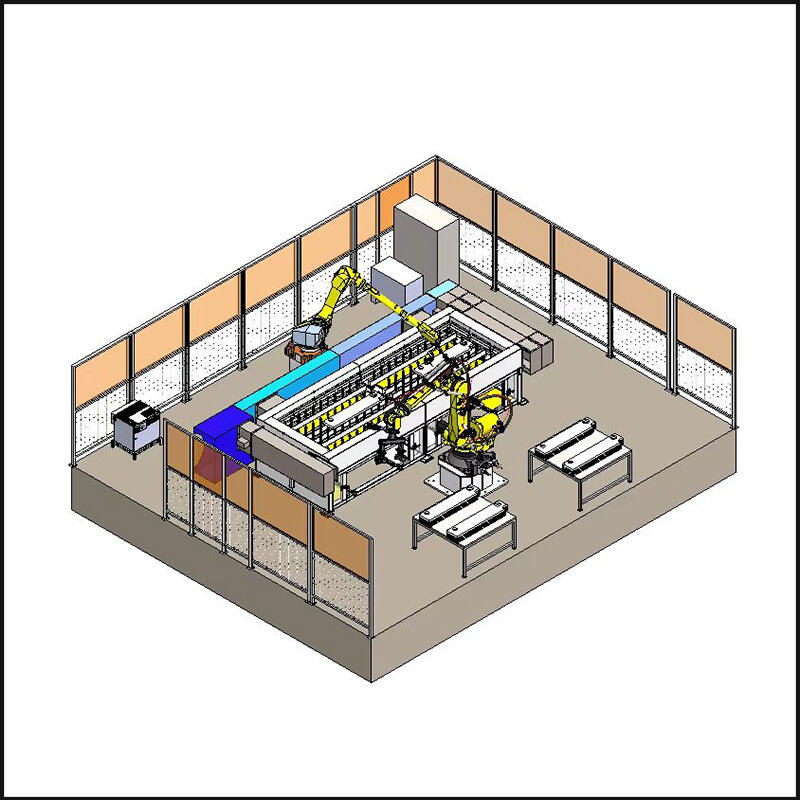

Costruisci flessibilmente una varietà di scenari di simulazione.

Integrano 100+ modelli di robot predefiniti, compatibili con tutti i modelli dei quattro grandi produttori di robot e delle marche nazionali regolamentari.

Ci vogliono solo 1~2 giorni per completare il debug della comunicazione del robot, ciclo di debug più breve e costo di debug inferiore.

modello digitale tridimensionale

Pronto - programmazione offline senza tempi morti. Il programma di produzione del giorno successivo/settimana/mese può essere preparato in anticipo per corrispondere al piano di pianificazione Mes.

Efficiente, senza insegnamento, programmazione parametrica e grafica, generazione automatica del programma entro 30 minuti che riduce la soglia di utilizzo.

Intelligente - genera report a intervalli regolari e ricorda le eccezioni. Aggiornamento e gestione in tempo reale della libreria di componenti, libreria di parametri e dati della libreria di progetti.

Generazione automatica del codice di movimento del robot, più robot, più assi esterni, posizionatore, che lavorano insieme. È possibile pianificare una traiettoria massima di 24 assi.

Realizza la simulazione del movimento del robot, la rilevazione di collisioni, l'evitamento di singolarità e la rilevazione dei limiti degli assi.

Rilevazione di collisioni, evitamento di singolarità e verifica della raggiungibilità dell'area di lavoro. Controllo tramite simulazione, soluzione a un clic per collisioni, singolarità, sovraccorrezione e aree irraggiungibili.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK