Kamera penglihatan binokuler 3D SmartVision

Sistem penglihatan cahaya terstruktur binokuler 3D SmartVision

- Ringkasan

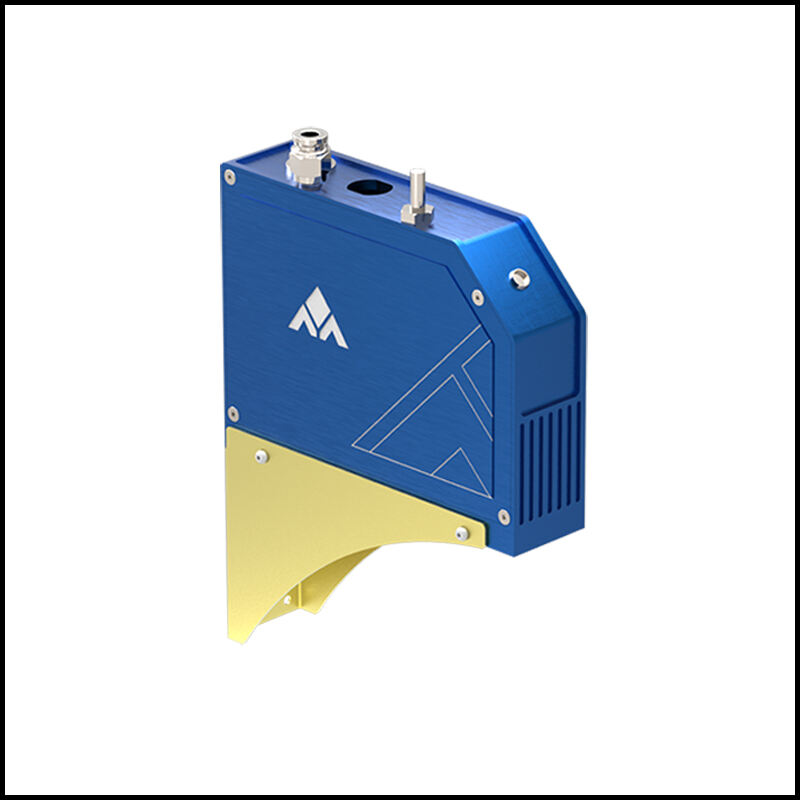

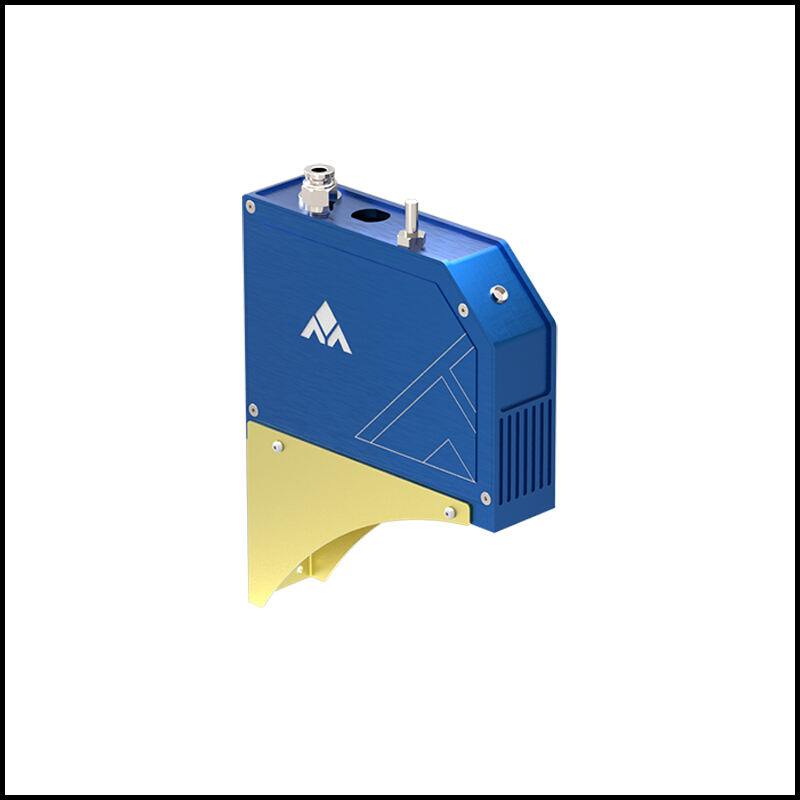

Kamera penglihatan binokuler 3D SmartVision

Menyediakan otak dan mata untuk robot.

Model produk

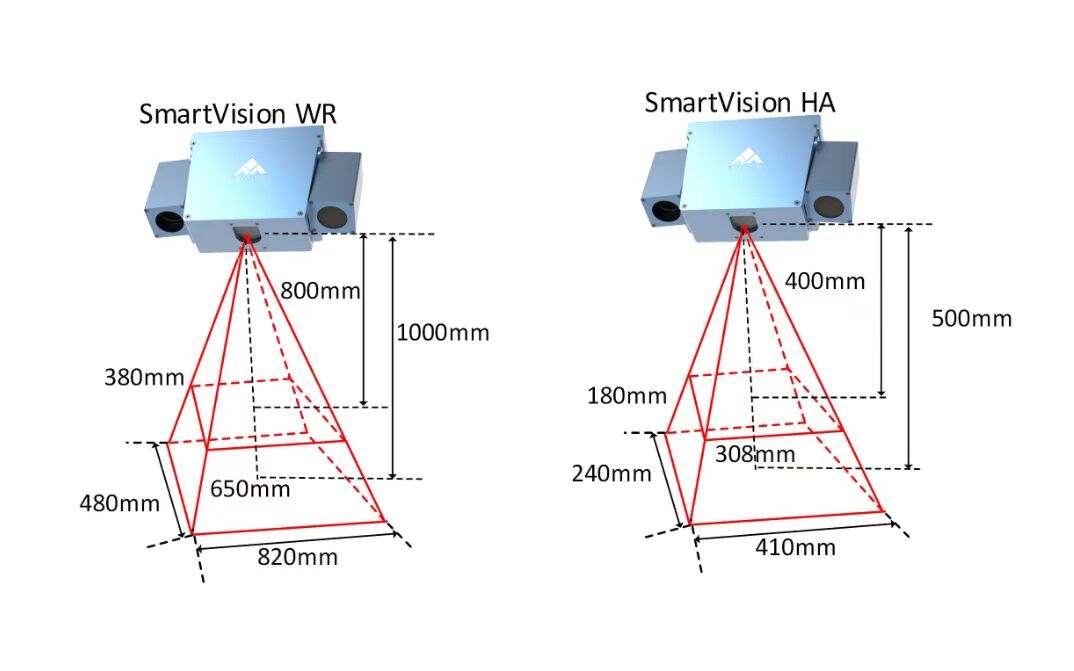

Produk seri SmartVison adalah sensor penglihatan cahaya terstruktur binokuler yang dikembangkan oleh Minyue Technology untuk aplikasi pengelasan dan pemotongan robot industri. Ada dua model umum SmartVison WR dan SmartVision HA presisi tinggi yang bergantung pada akurasi dan jangkauan.

Parameter utama

| Nomor PROYEK | Parameter | SmartVison WR |

| 1 | Jarak operasi (mm) | 800-1000 |

| 2 | Jarak pandang dekat (mm) | 650*380 |

| 3 | Jarak pandang jauh (mm) | 820*480 |

| 4 | Resolusi (Pix) | 1624*1240 |

| 5 | Piksel (MP) | 2 |

| 6 | Akurasi pengukuran (mm) | 0.5 |

| 7 | Akurasi kalibrasi (mm) | 0.03 |

| 8 | Waktu pengambilan (dtk) | 1 |

| 9 | Ukuran keseluruhan (mm) | 233 * 76 * 121 |

| 10 | Berat (kg) | 3 |

| 11 | Kisaran suhu pengoperasian (℃) | 0 ~ 45º |

| 12 | port komunikasi | Port Gigabit Ethernet |

| 13 | Tegangan operasi (V) | 12 |

| 14 | Tingkat perlindungan | IP65 |

Karakteristik produk

1. Dapat mengeluarkan data 3D berkualitas tinggi untuk berbagai benda kerja logam, yang dapat memenuhi beragam persyaratan cahaya anti-lingkungan, presisi tinggi, kecepatan tinggi, dan volume kecil dalam berbagai permintaan.

2.Dapat memiliki tingkat presisi tinggi, kecepatan tinggi, dapat disesuaikan, bidang penglihatan dapat memenuhi kebutuhan aktual dari pemandangan umum.

3. Mengintegrasikan visi 3D, pembelajaran mendalam, perencanaan gerak dan teknologi lainnya, mengadopsi grafik tanpa pemrograman yang dapat melakukan penarikan modular, perkabelan, konfigurasi parameter, dan fungsi non-pemrograman.

4.Mengadopsi bahan paduan aluminium, cangkang tertutup sepenuhnya, kelas perlindungan IP65, tegangan operasi 24V, telah lulus sertifikasi CEFCCVCCI dan RoHS. Dapat mengatasi debu, getaran, kelembapan, gangguan elektromagnetik, dan lingkungan keras lainnya dengan lebih baik.

Produk cerdas Minyue

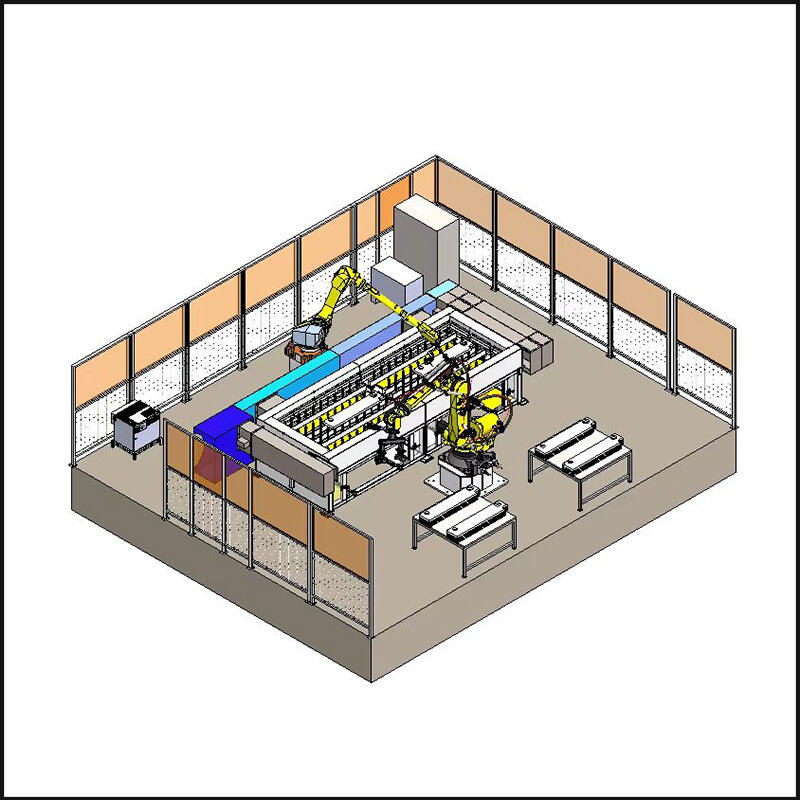

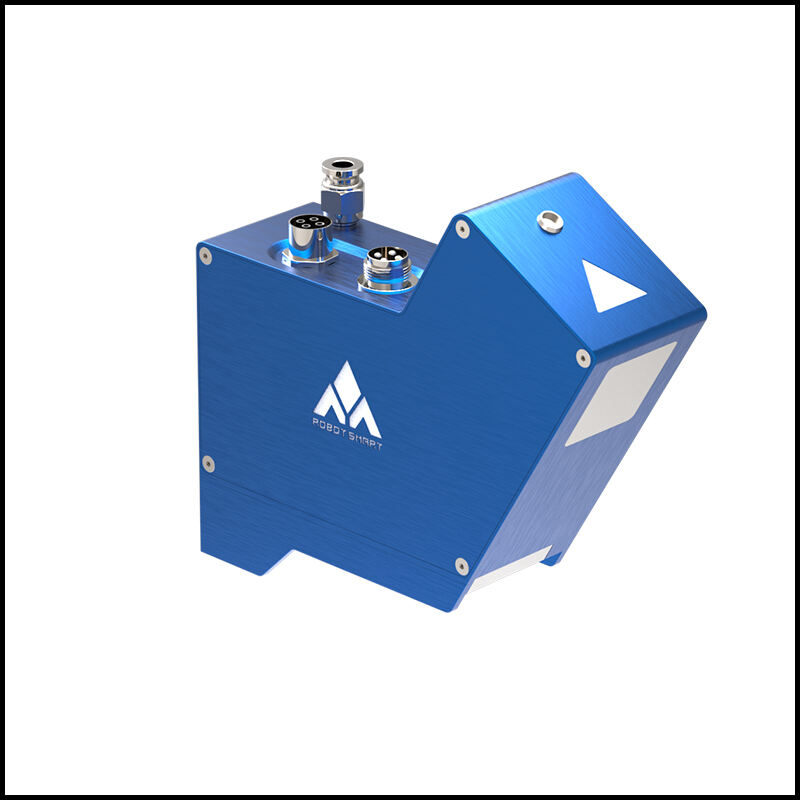

Sistem pelacakan jahitan laser

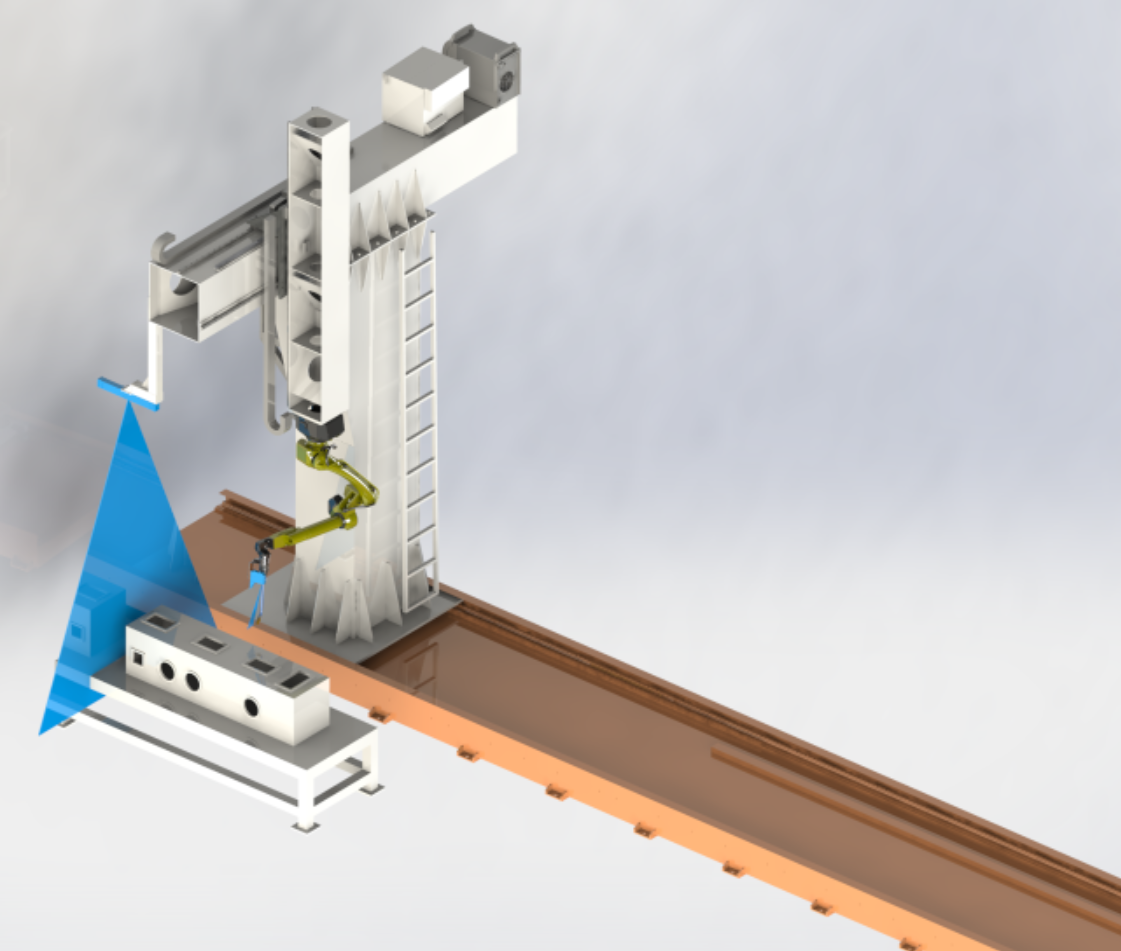

Banyak masalah seperti lingkungan pengelasan yang buruk, intensitas tenaga kerja yang tinggi, efisiensi pengelasan yang rendah dan kesalahan pemrosesan yang besar telah mengganggu industri pengelasan robot industri.Melalui sistem pelacakan jahitan laser SmartEye untuk identifikasi dan pemosisian,secara efektif memecahkan masalah konsistensi benda kerja yang buruk, kesalahan pemrosesan, celah kelompok las tidak teratur, mengurangi banyak pekerjaan perbaikan dan penggilingan manual berikutnya, tidak hanya membebaskan tenaga kerja, tetapi juga meningkatkan efisiensi kerja

Perangkat lunak pemrograman offline

Dengan meningkatnya permintaan secara bertahap akan produksi yang beraneka ragam, dalam jumlah kecil dan fleksibel, pasar memiliki persyaratan yang lebih tinggi terhadap kenyamanan pemrograman robot, dan robot pengajaran dan reproduksi tradisional tidak dapat memenuhi permintaan pasar.Sistem pemrograman off-line Minyue -RobotSmart dapat dengan cepat menghasilkan lintasan robot, secara efektif memecahkan masalah pemrograman seperti pengajaran lintasan pengelasan yang rumit, efisiensi pemrograman yang rendah, dan tingkat pemanfaatan robot yang rendah.

1. Teknologi Minyue secara independen mengembangkan sistem pelacakan jahitan laser inti dan produk perangkat lunak pemrograman offline dan menggabungkannya dengan aplikasi

2.Kombinasi beberapa produk yang dikembangkan secara independen dapat dengan cepat mewujudkan persyaratan aplikasi cerdas pelanggan

3. Perangkat lunak pemrograman offline dengan cepat menghasilkan lintasan, visi untuk memastikan akurasi lintasan, kombinasi kedua produk untuk mencapai "1+1" lebih besar dari 2

4. Saat ini, produk kami memiliki aplikasi yang matang dalam pembuatan kapal, pelat kereta dan industri pengelasan lainnya untuk membantu peningkatan cerdas pengelasan robot dan manufaktur pemotongan

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK