एक दुनिया की कल्पना करें जहाँ रोबोट हमारे सभी काटने का काम करते हों। ठीक है, अब बताइए क्या? वह दुनिया अब पहुँच गई है! रोबोट कटिंग (या कुछ लोगों में रोबो कटिंग कहा जाता है), यह हमारे काटने की विधि को बदल रहा है। यह काम अब मशीनों द्वारा किया जा सकता है, जिसे एक व्यक्ति करने की जरूरत नहीं होती। उन मशीनों द्वारा चीजें काटी जाती हैं जो हम मानवों की तुलना में अधिक सटीकता और दक्षता से होती हैं। यह तकनीकी कटिंग में एक महत्वपूर्ण मilestone है, और यह कारखानों में उत्पादों के निर्माण को क्रांति ला रहा है।

पुरानी हाथ से सब कुछ काटने की विधि अब बीती हुई है। एक नयी युग आ गया है, जहाँ मशीनें उस काम को कर रही हैं, जो अब वास्तव में अद्भुत परिणाम उत्पन्न कर सकती है। रोबो कटिंग निर्माण के क्षेत्र में सबसे बड़े परिवर्तनों में से एक है। "इस शानदार तकनीक के कारण कटिंग तेजी से और बेहतर तरीके से की जा सकती है।" यह कार्यकर्ताओं को बहुत समय बचाता है और एक बार बहुत सारे टुकड़े काटने वाले रोबोट के कारण व्यवसाय को अधिक सुचारु रूप से काम करने की अनुमति देता है।

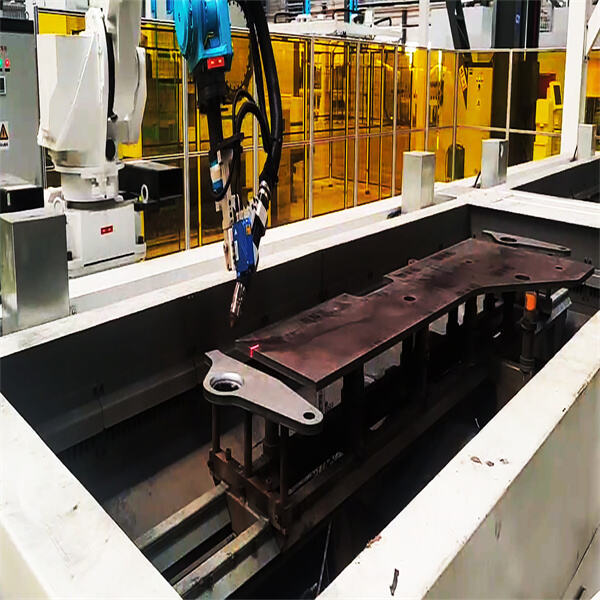

MINYUE रोबोटिक स्पॉट वेल्डिंग , कारखाने उत्पादों की बढ़ी हुई संख्या उत्पन्न कर सकते हैं जिसमें हाथ से काटने से जुड़े देरी के खतरे नहीं होते। बाजार में उत्पादों की मांग के साथ गति बनाए रखने से ग्राहकों को बेहतर सेवा प्रदान की जाती है और व्यवसाय का निरंतर प्रवाह बना रहता है। कारखाने रोबोट का भी उपयोग कर सकते हैं ताकि काटने के दौरान त्रुटियों का खतरा कम हो, जो मानवीय हस्तक्षेप के कारण हो सकती है। इससे ग्राहकों की आवश्यकताओं को पूरा करने वाले अधिक सटीक उत्पाद प्राप्त होते हैं।

रोबो के द्वारा काटना बहुत शानदार है और यह पैसे और समय भी बचाता है। काटने के लिए रोबोट इंसानों की तुलना में कहीं तेज़ काम कर सकते हैं। यह कारखानों के लिए एक विजय है क्योंकि यह उन्हें बहुत जल्दी से अधिक वस्तुएं बनाने की अनुमति देता है। क्योंकि रोबोट बहुत सटीक होते हैं, काट बहुत उच्च गुणवत्ता की होती है। सभी टुकड़ों को एक ही आकार और आकृति में काटना अंतिम उत्पाद के रूप में सही ढंग से फिट होने के लिए महत्वपूर्ण है।

यह पूरे उत्पादन प्रक्रिया को तेज़ करने और सरल बनाने में भी मदद करता है। यह व्यवसायों को धन बचाने में मदद करता है क्योंकि वे अधिक उत्पादन कर सकते हैं बिना नए कर्मचारियों को भरती किए। रोबोट कटिंग कम्पनियों को गुणवत्तापूर्ण उत्पाद बनाने पर ध्यान केंद्रित करने में मदद करती है जो खरीदारों को पसंद आएंगे और सस्ते मूल्य पर उपलब्ध होंगे।

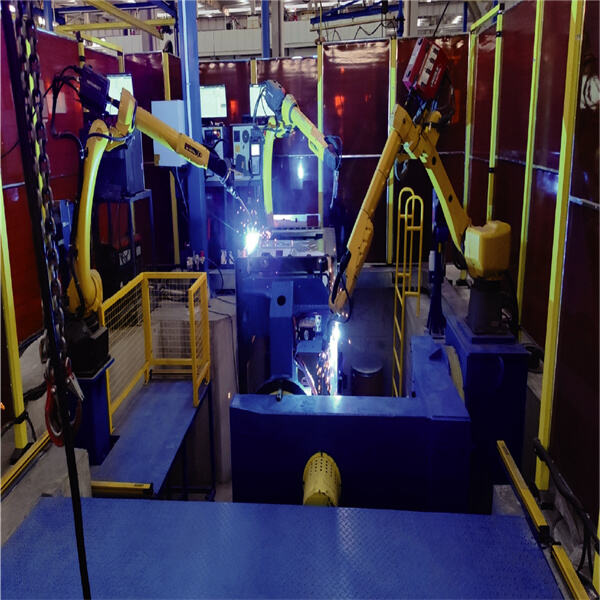

अगर आप अभी भी अपनी सिगरेट को काटने के पुराने तरीकों का इस्तेमाल कर रहे हैं, और अगर आपका एक व्यवसाय है, तो वास्तव में आप कई चीजों से बच रहे हैं! समय बचाएं, लागत कम करें और गुणवत्ता में सुधार करें रोबोट का उपयोग करके MINYUE कटिंग मशीन का उपयोग करें, वे शीर्ष कटिंग मशीनें आपके व्यवसाय को अधिक प्रतिस्पर्धी बना सकती हैं! MINYUE robotic welding cell तेजी से और सटीक कटिंग करने में सक्षम हैं जो सबसे अच्छे संभावित परिणामों की गारंटी देती है।

MINYUE सीखना स्वचालित वेल्डिंग रोबोट आपके व्यवसाय को फायदा पहुंचा सकता है यह बहुत महत्वपूर्ण है। यह न केवल आपको समय और पैसा बचाने में मदद कर सकता है, बल्कि आपको अपने ग्राहकों को बेहतर सेवा देने में भी मदद कर सकता है। नवीनतम कटिंग प्रौद्योगिकियों का उपयोग करके ग्राहकों की आवश्यकताओं को पूरा करने और अपनी आवश्यकताओं को पूरा करने के लिए आगे बढ़ें।

तेज, सटीक, पूरी तरह से कोई प्रोग्रामिंग नहीं, उच्च कार्यक्षमता और उच्च सटीकता। यह पारंपरिक रोबोटों की जटिल शिक्षण प्रक्रिया को हल करता है और शिक्षण प्रक्रिया के दौरान बंद रहने को बचाता है।

बीजिंग मिन्युए टेक्नोलॉजी को., लिमिटेड, दुनिया की सबसे अग्रणी हाई-टेक उद्यमों में से एक है जो औद्योगिक रोबोटों के गैर-शिक्षण-आधारित बुद्धिमान अनुप्रयोगों पर केंद्रित है। हम फ्लेक्सिबल बुद्धिमान विनिर्माण में विशेषज्ञ हैं, जिसमें हमारे स्व-विकसित RobotSmart - बुद्धिमान निर्णय लेने वाला प्रणाली, SmartVision - दोनों आँखों वाला संरचित प्रकाश दृष्टि प्रणाली, और SmartEye - लेजर दृष्टि खिड़की पीछा प्रणाली शामिल है। बुद्धिमान रोबोट वेल्डिंग और कटिंग के लिए एक नई पीढ़ी के समाधान प्रदान करते हैं।

बहुत सारे रोबोटों, बहुत सारे बाहरी अक्षों और स्थिति-निर्धारक के लिए सहयोगी कार्य के लिए शक्तिशाली वेल्डिंग रोबोट पूर्व लोडिंग, पार्श्व लोडिंग, उलटा लोडिंग, गेनtry माउंटिंग, बुद्धिमान त्रयाक्षीय योजना प्रदान करते हैं। रोबोट गति सिमुलेशन, संघटना का पता लगाएं, एकलता से बचना और अक्ष सीमा का पता लगाएं।

फाइंडिंग और ट्रैकिंग की सुविधा का उपयोग करके, वेल्ड सीम को स्कैन करना, वेल्ड सीम की स्थिति और जानकारी की पुष्टि करना, 3D डिजिटल मॉडल ड्राइंग और वास्तविक कार्यपट्टी के बीच वेल्ड सीम की स्थिति को सही करना, और आगंतुक सामग्री की त्रुटि और थर्मल विकृति के कारण वेल्ड की बाधा समस्या को हल करना।