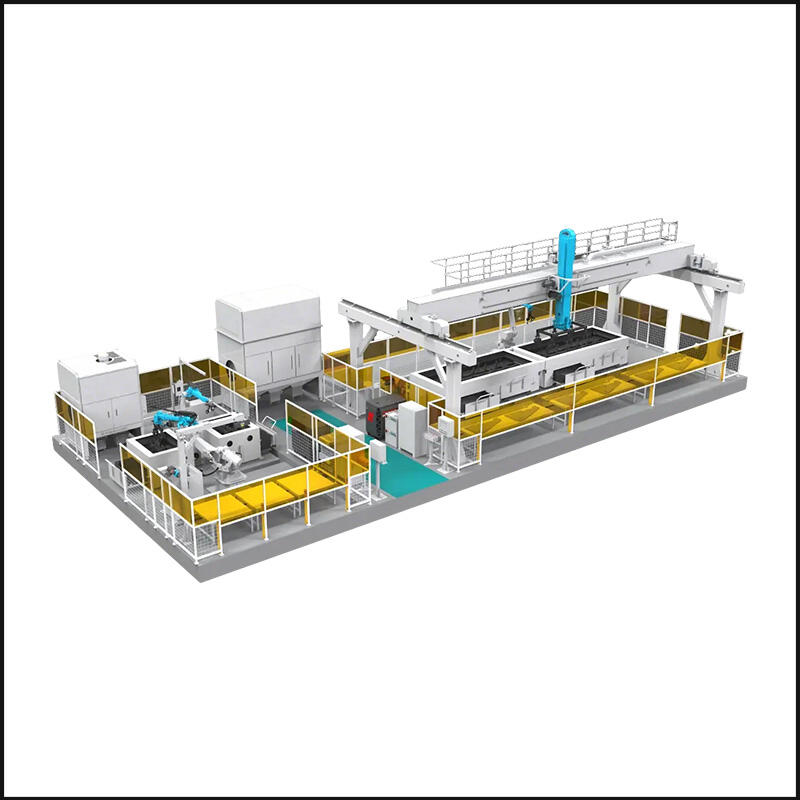

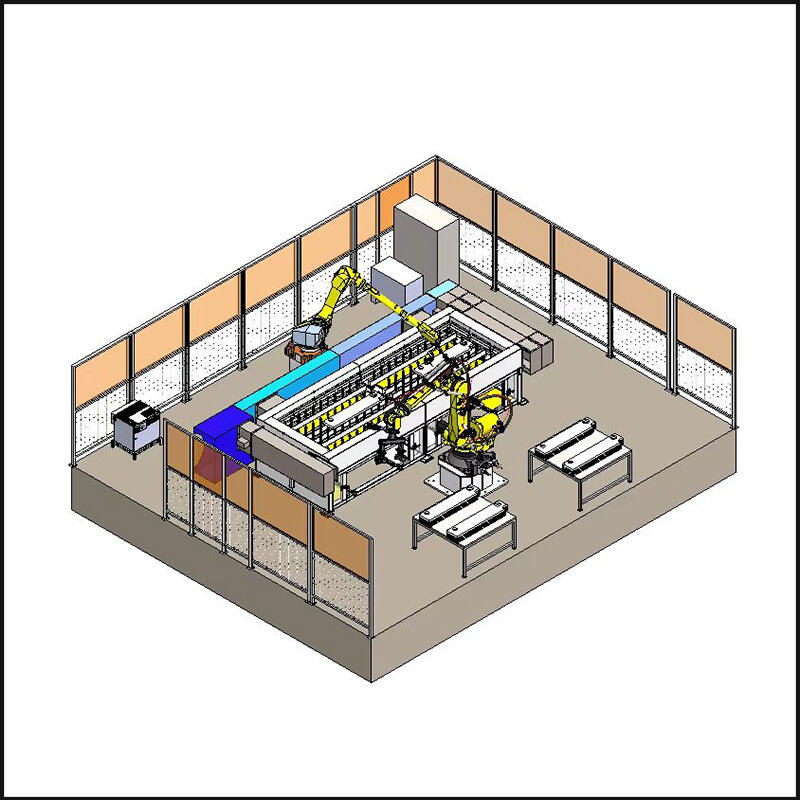

- Vista xeral

O sistema de control de soldadura intelixente sen ensino da MINYUE Technology dedícase ao campo da automatización robótica de soldadura con anos de experiencia. Para resolver o punto doloroso da industria. Como a crecente escasez de soldadores, a insuficiente precisión no descarga e montaxe de pezas, unha gran cantidade de pezas non estándar e en pequena cantidade necesarias na construción metálica, construcción naval, industria pesada, fabricación, etc. Ofrece a solución de soldadura intelixente caracterizada pola súa plena integración e as vantaxes sen ensino.

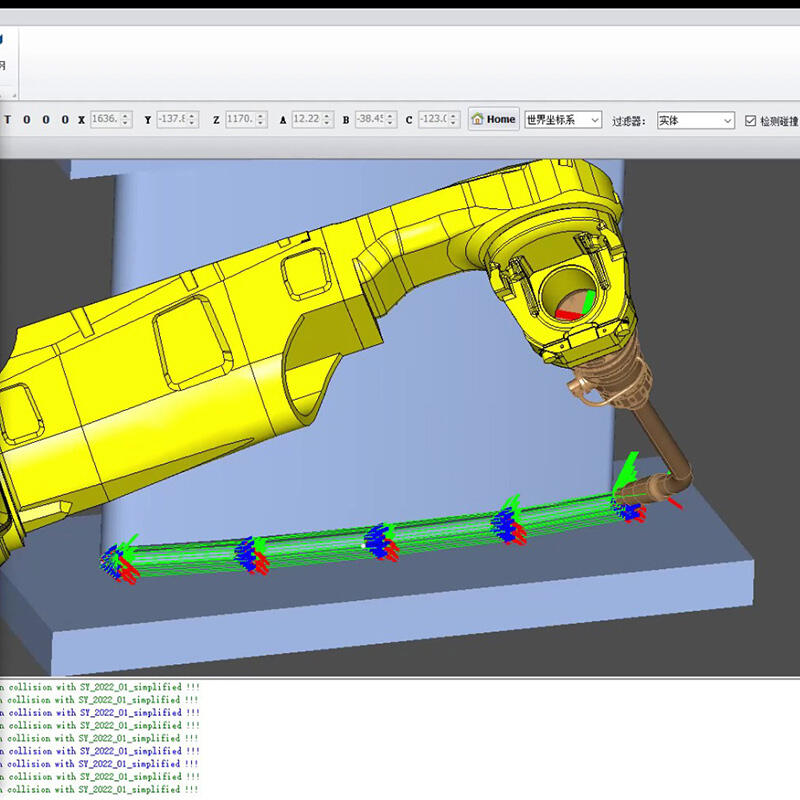

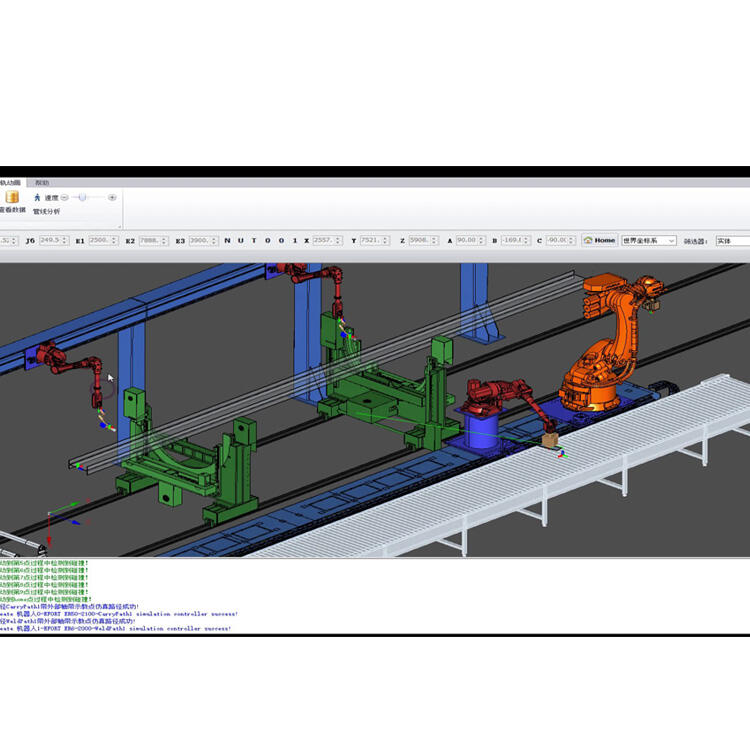

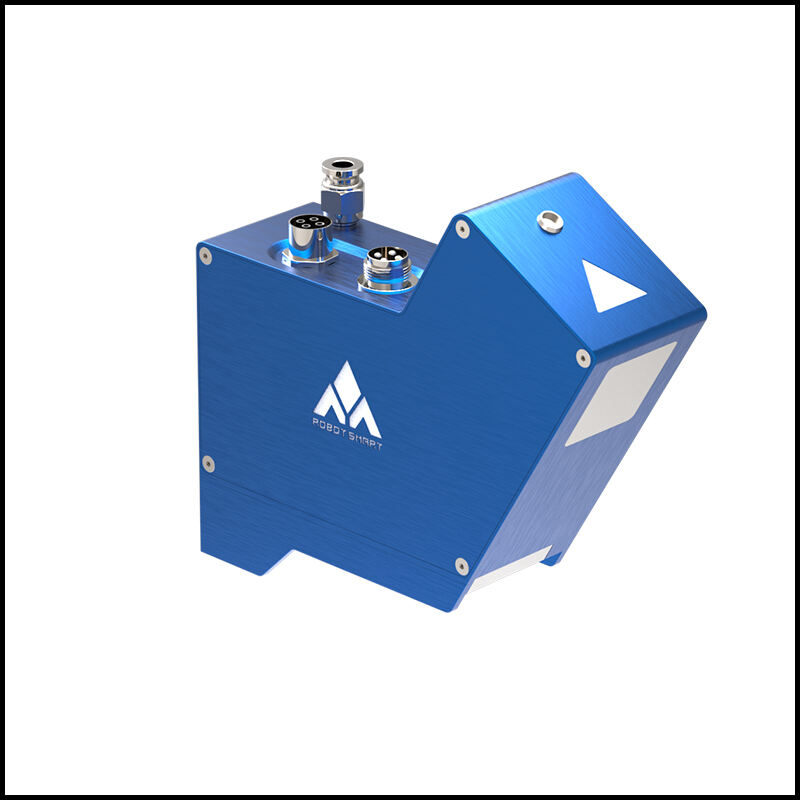

Sistema de soldadura sen ensino

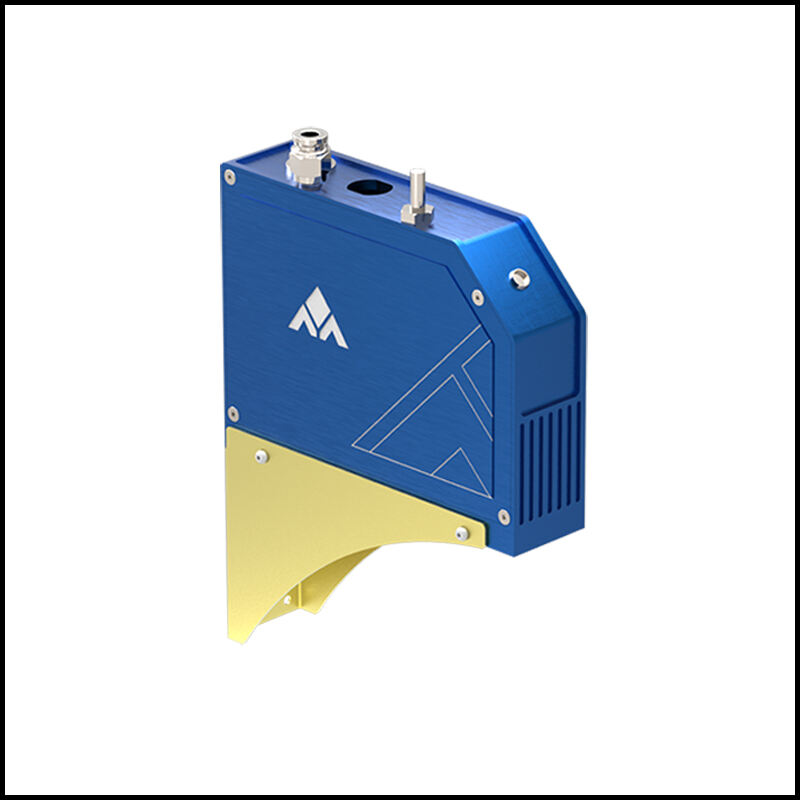

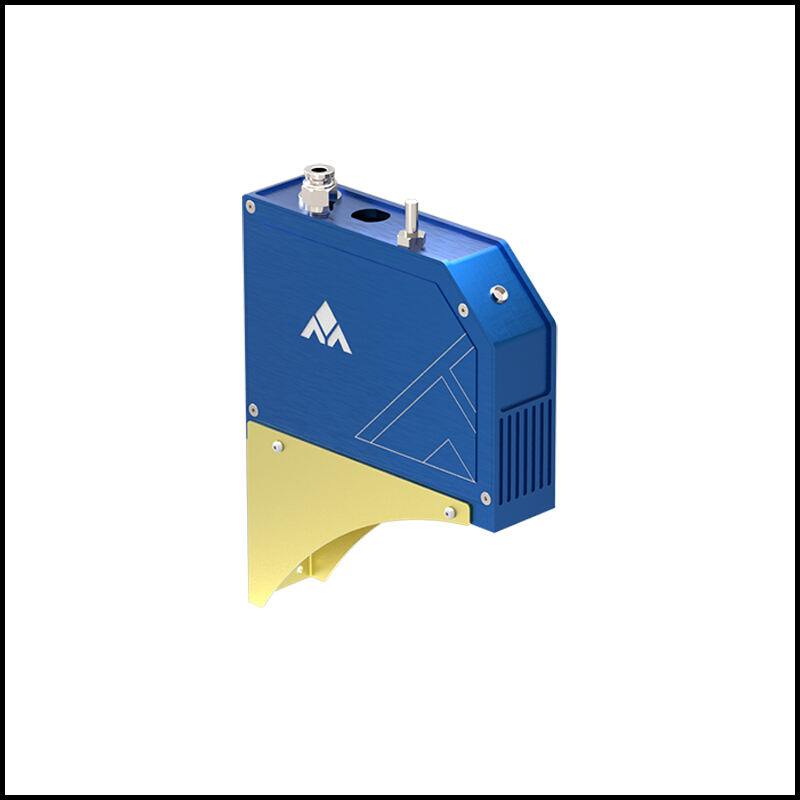

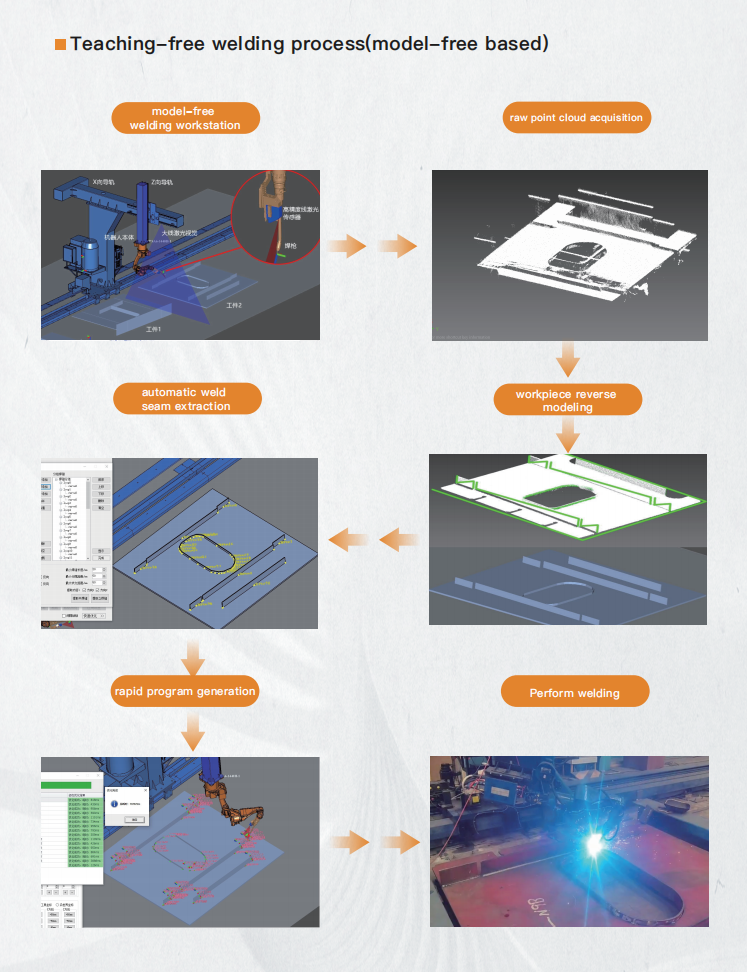

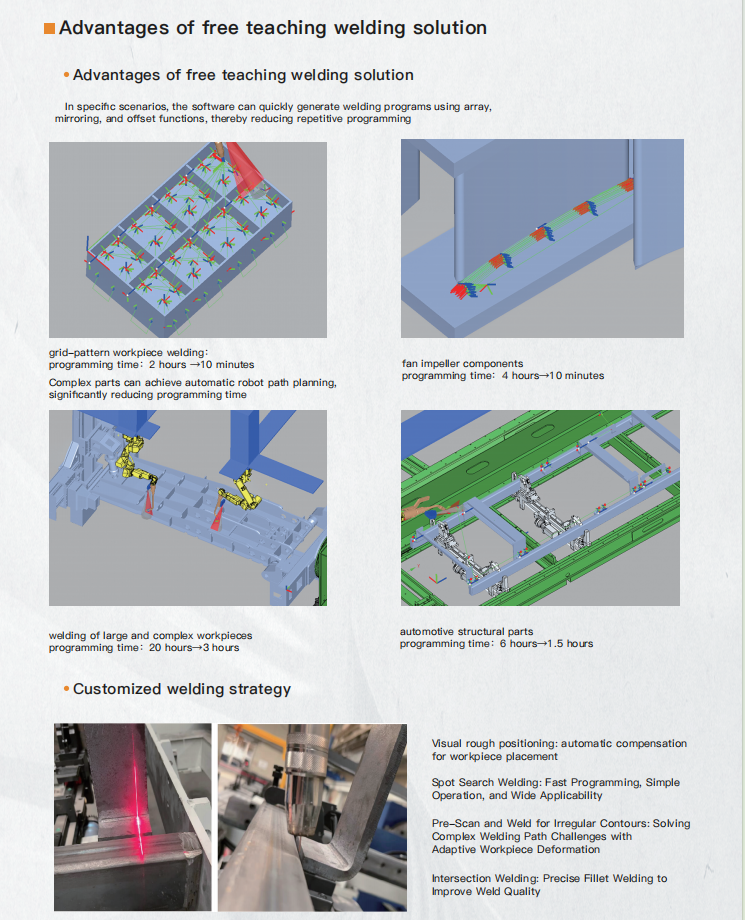

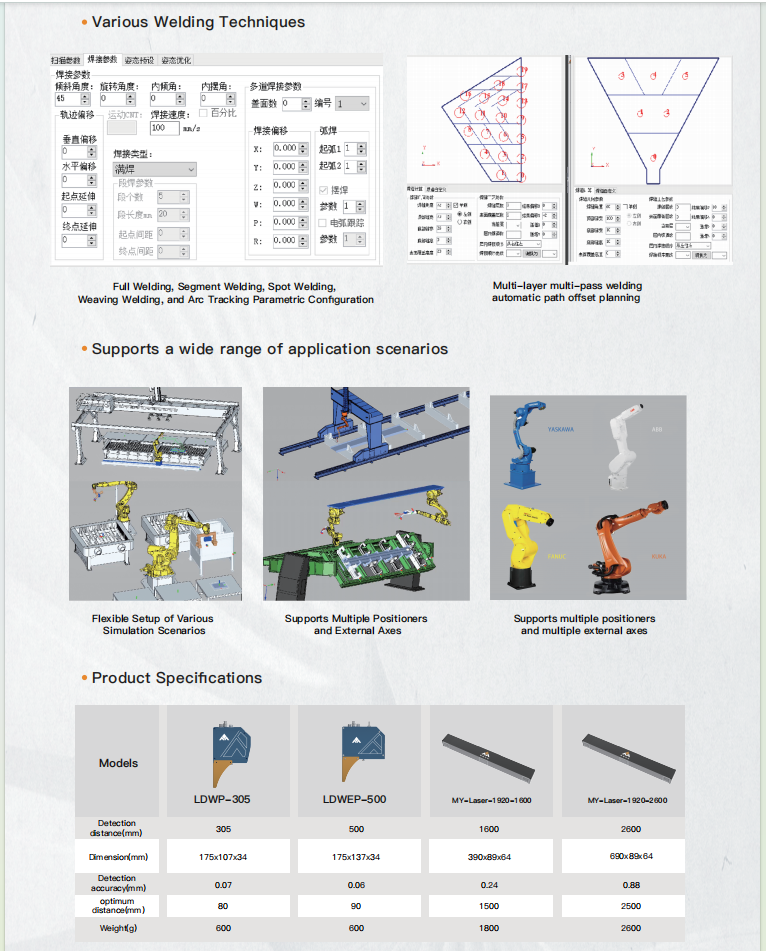

O sistema de soldadura sen ensino apoia as principais marcas de robots, incluíndo KUKA, FANUC, ABB e Yaskawa, así como marcas nacionais como Siasun, Estun e Efort. Integrando o sistema de visión láser autodesenvolvido SmartEye, o sistema de soldadura e corte sen ensino consta dun sistema de decisión intelixente (RobotSmart), un sistema de seguimento de visión láser (SmartEye) e un sistema de modelado de visión de gran campo de visión (SmartVision). A través da colaboración entre os tres sistemas, importando dibuxos 3D no sistema de programación offline RobotSmart, xerando trayectorias de soldadura para robots (incluíndo puntos de escaneo, puntos de soldadura, instrucións de soldadura, etc.) Modelado inverso das pezas coa cámara de escaneo de liña larga do sistema SmartVision. Posicionamento preciso das costuras de soldadura mediante o sensor de visión láser do sistema SmartEye. Realiza a soldadura automática sen ensino do traballo actual.

Axuda aos fabricantes a superar os desafíos da alta complexidade de programación e baixos niveis de automatización, mentres tamén cumple cos requisitos de produción de soldadura para lotes pequenos e diferentes tipos de pezas, mejorando así a eficiencia do procesamento e o rendemento do produto.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK