- Resumen

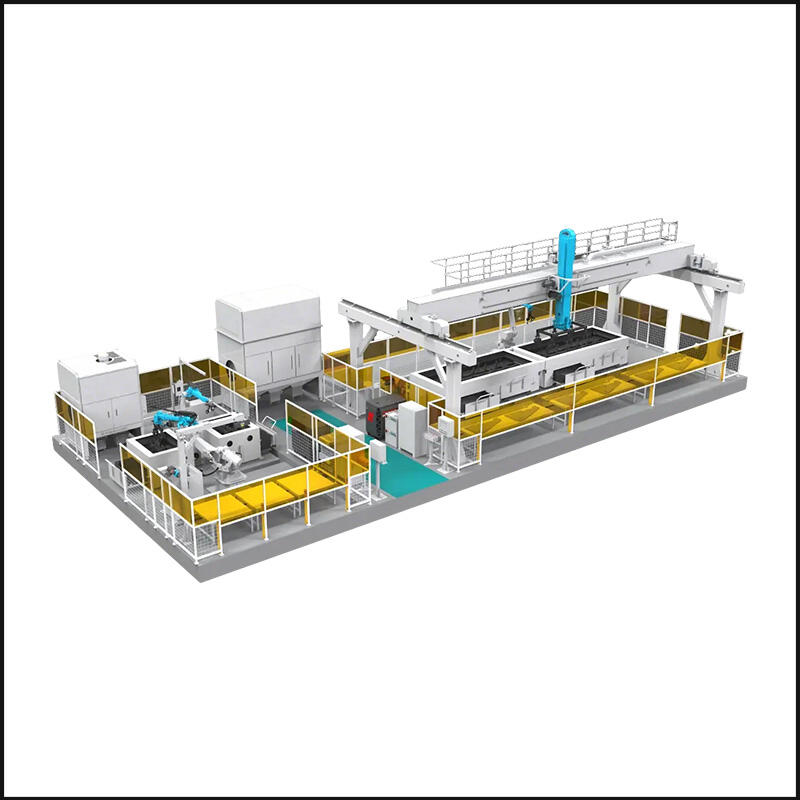

El sistema de control de soldadura inteligente sin enseñanza de MINYUE Technology ha estado dedicado al campo de la automatización robótica de soldadura con años de experiencia. Para resolver el punto doloroso de la industria. Por ejemplo, la creciente escasez de soldadores, la insuficiente precisión en el desmontaje y ensamblaje de piezas, una gran cantidad de piezas no estándar y de pequeñas cantidades necesarias en la construcción de acero, construcción naval, industria pesada, fabricación, etc. Ofrece una solución de soldadura inteligente caracterizada por su integración total y sus ventajas sin enseñanza.

Sistema de soldadura sin enseñanza

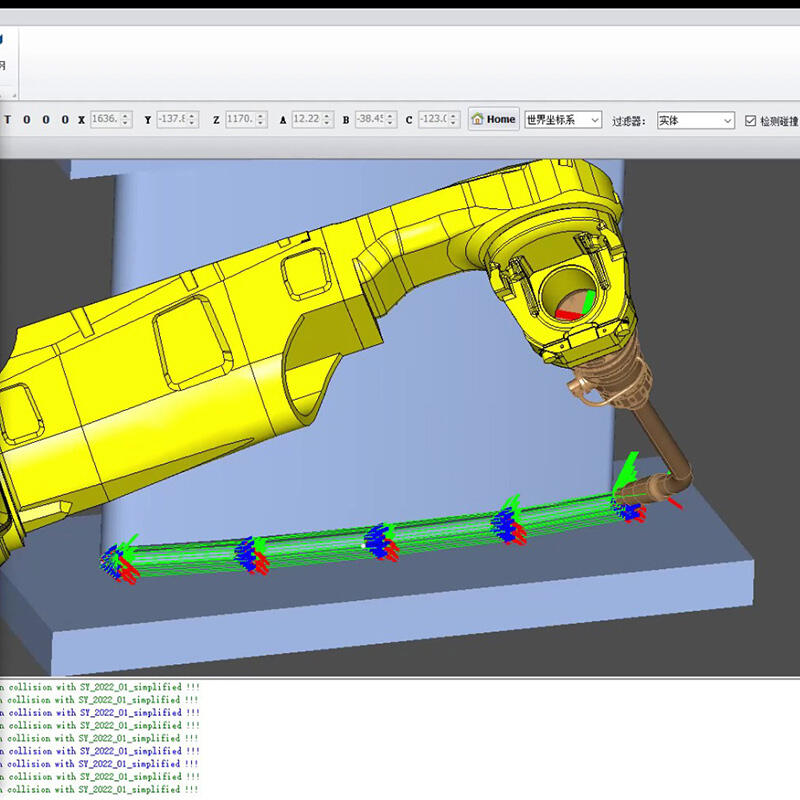

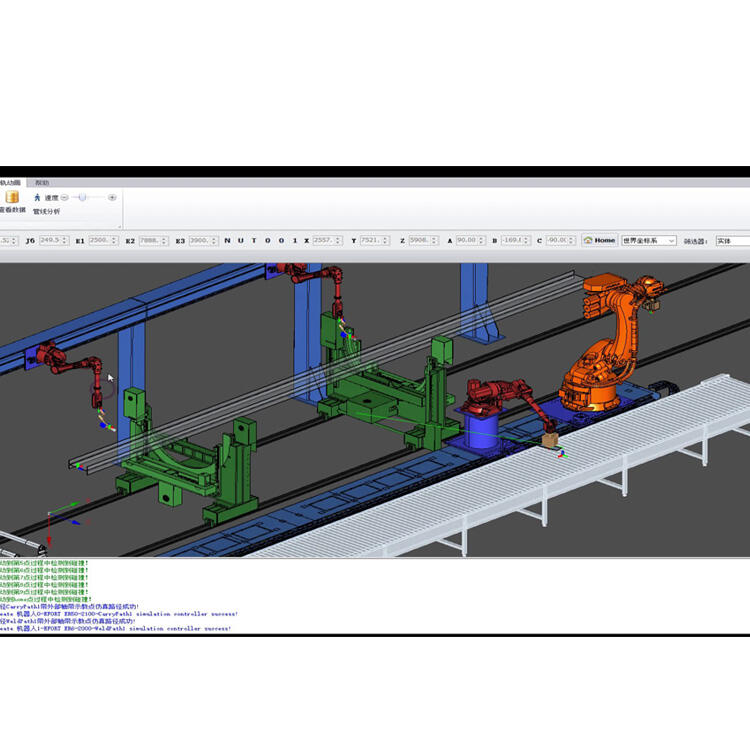

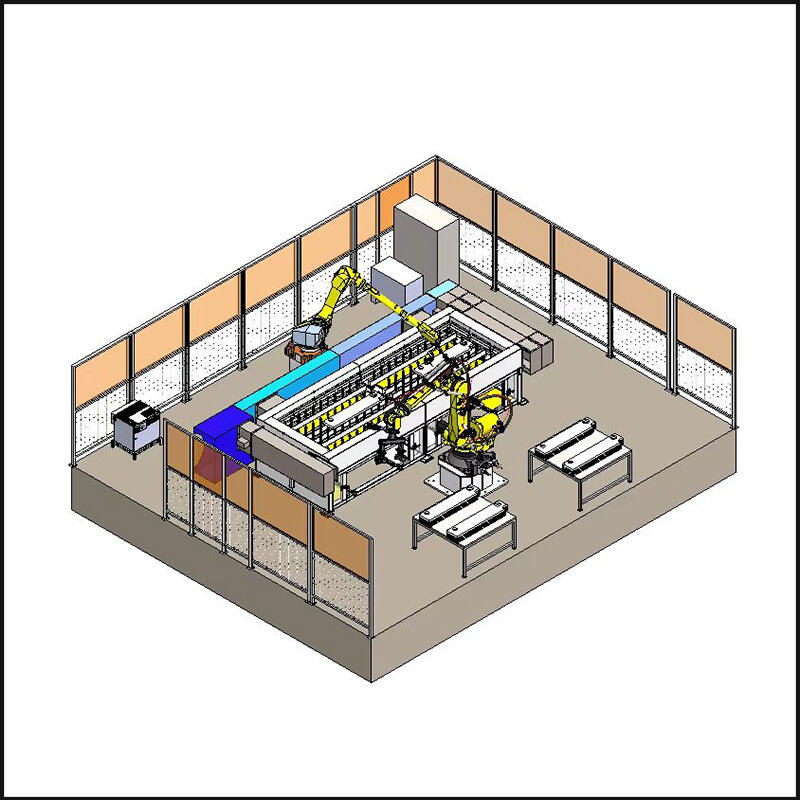

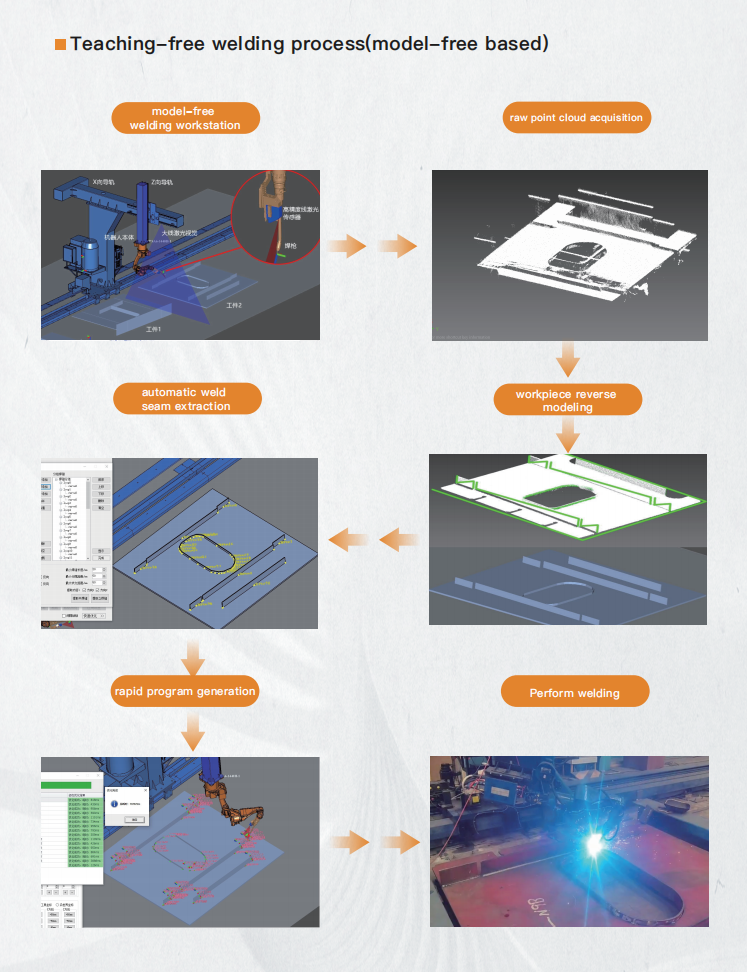

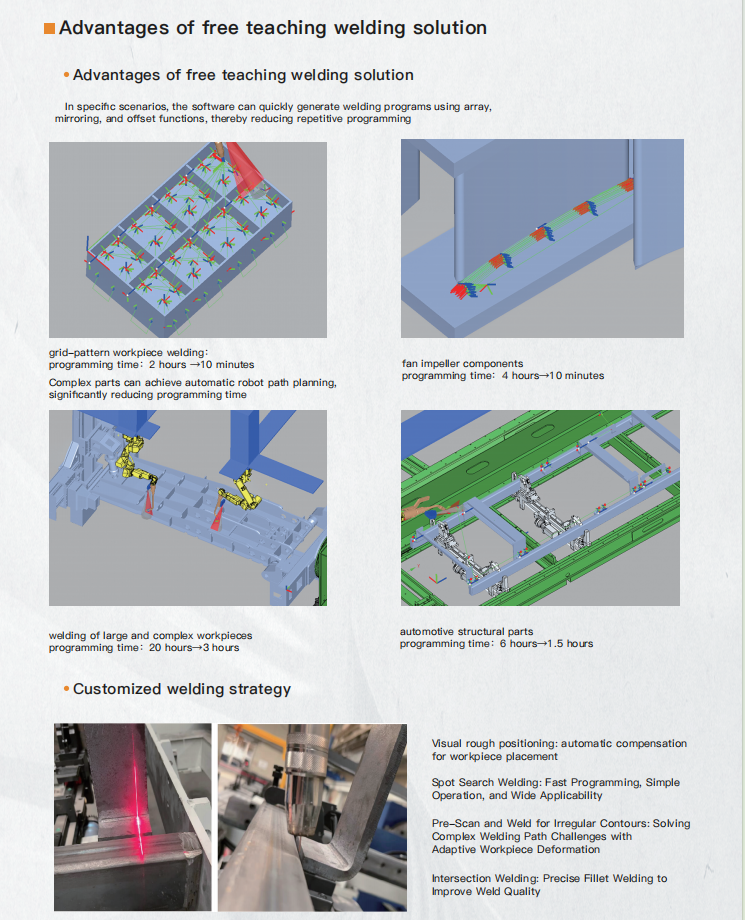

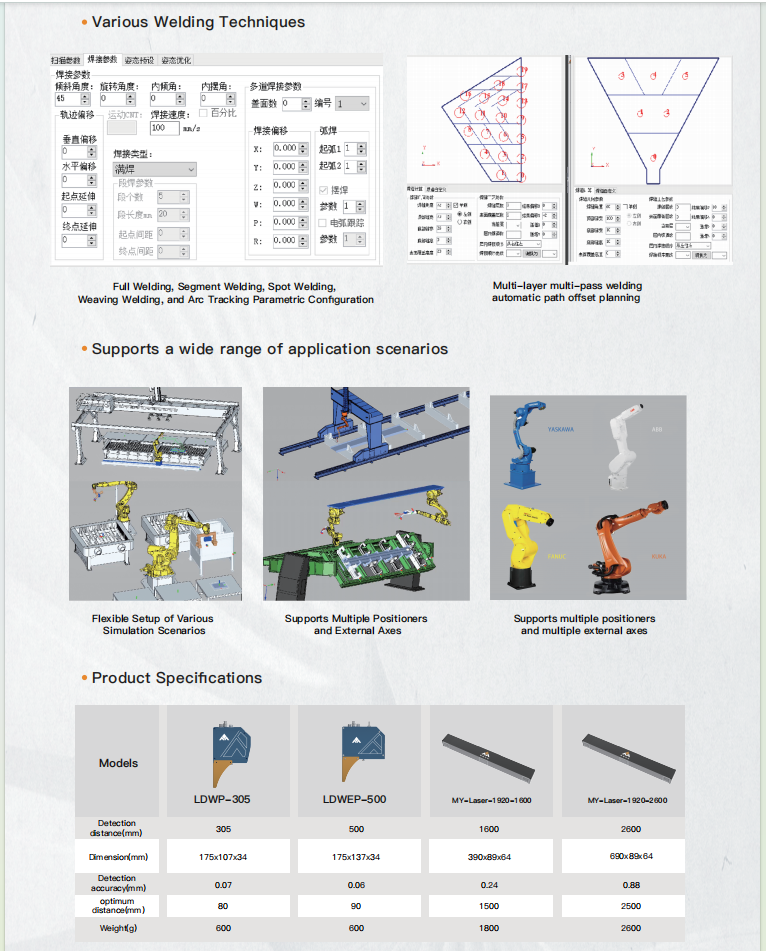

El sistema de soldadura sin enseñanza Teaching-free soporta las principales marcas de robots, incluidas KUKA, FANUC, ABB y Yaskawa, así como marcas nacionales como Siasun, Estun y Efort. Al integrar el sistema de visión láser autodesarrollado SmartEye, el sistema de soldadura y corte sin enseñanza consta de un sistema de toma de decisiones inteligente (RobotSmart), un sistema de seguimiento de visión láser (SmartEye) y un sistema de modelado de visión de gran campo de visión (SmartVision). A través de la colaboración entre los tres sistemas, al importar dibujos 3D en el sistema de programación offline RobotSmart, se genera trayectorias de soldadura para robots (incluyendo puntos de escaneo, puntos de soldadura, instrucciones de soldadura, etc.). Modelado inverso de piezas con la cámara de barrido de línea grande del sistema SmartVision. Posicionamiento preciso de juntas de soldadura mediante el sensor de visión láser del sistema SmartEye. Realiza la soldadura automática sin enseñanza del trabajo actual.

Ayuda a los fabricantes a superar los desafíos de una alta complejidad de programación y bajos niveles de automatización, mientras también cumple con los requisitos de producción de soldadura para lotes pequeños y diferentes tipos de piezas, mejorando así la eficiencia del procesamiento y el rendimiento del producto.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK