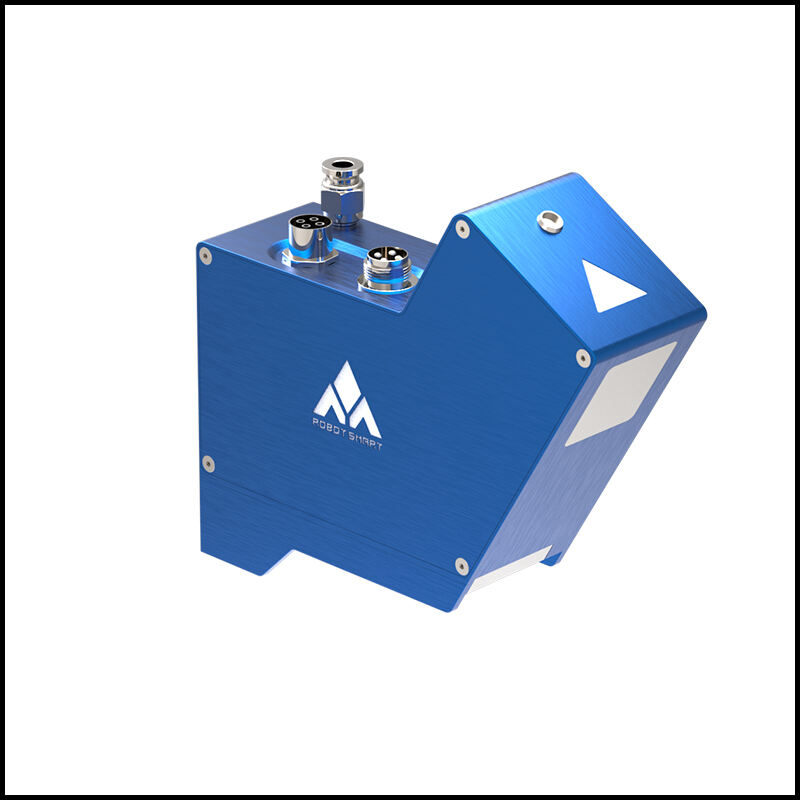

SLHA-85 Αισθητήρας μετακινητικότητας ζωντανής συνδέσεως με λέιζερ

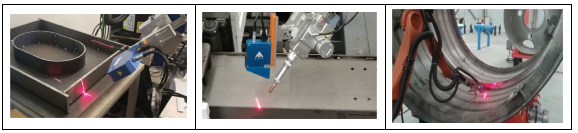

Με εύρεση θέσης, παρακολούθηση σε πραγματικό χρόνο, σάρωση και λειτουργία αυτόματης συνδεσιμότητας.

- Περιγραφή

- Υποστήριξη μάρκας ρομπότ

Το αισθητήρας παρακολούθησης συνδέσεων με λέιζερ χρησιμοποιεί έναν λέιζερ για να εκλάμβανε την επιφάνεια της σύνδεσης και να δημιουργεί μια γραμμή φωτός λέιζερ, η οποία καταλαμβάνεται και εικονογραφεί από μια υψηλής ευκρίνειας κάμερα. Με τη χρήση αλγορίθμων επεξεργασίας, οι τριδιάστατες χαρακτηριστικές της σύνδεσης μετατρέπονται σε δομημένες πληροφορίες, συμπεριλαμβανομένων των συντεταγμένων των συνδέσεων, της ασύμμετρης κατανεμημένης φόρτωσης και των χαλώσεων. Αυτές οι πληροφορίες μεταφέρονται στον ελεγχέα του ρομπότ, παρέχοντας στο ρομπότ τις απαιτούμενες παραμέτρους τροχιάς και διαδικασίας για τη σύνδεση, καθοδηγώντας το ρομπότ να συνδέσει ή να τροποποιήσει τις αποκλίσεις των εργασιών σε πραγματικό χρόνο και επιτυγχάνοντας τέλεια εργασία σύνδεσης. Σε σύγκριση με άλλες λύσεις, η παρακολούθηση συνδέσεων με λέιζερ διαθέτει τις προνομιακές ιδιότητες μη επαφικής λειτουργίας, υψηλής ακρίβειας, ταχείας ταχύτητας και καλής προσαρμοστικότητας.

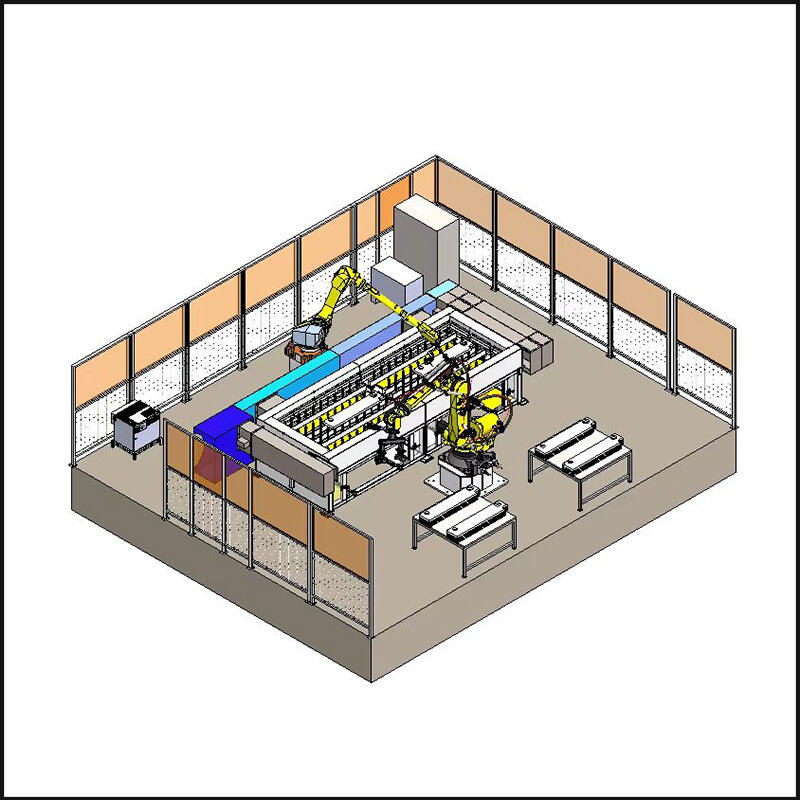

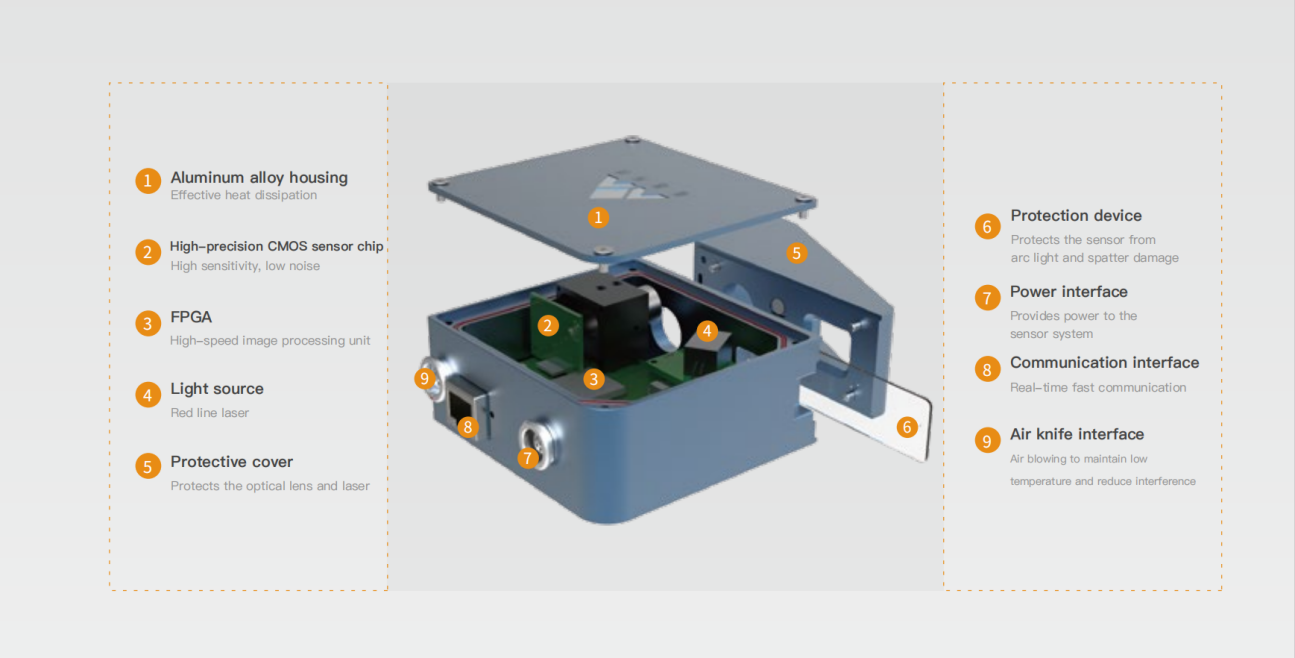

Ο αισθητήρας χρησιμοποιεί μέτρηση γραμμικού δομημένου φωτός, η οποία έχει γρήγορη ταχύτητα γραμμικής εικόνας, χωρίς επαφή και χωρίς μηχανική κίνηση. Δυνατή αποδοχή, ικανή να εξάγει παραμέτρους συρραφής. Πλήρως ενσωματωμένος, με εξωτερικούς βιομηχανικούς υπολογιστές και πολλά άλλα προβάδια, χρησιμοποιείται ευρέως σε διαφορετικούς τύπους αυτοματοποιημένης συρραφής. Ανεξάρτητα από τη διαδικασία συρραφής, μπορούμε να προσφέρουμε αξιόπιστη υποστήριξη και σταθερή απόδοση για να εξασφαλίσουμε εξαιρετικά αποτελέσματα σε διαφορετικά σενάρια συρραφής.

Πλήρως γραφική λογισμική διεπαφή, διαδικασία ρύθμισης παραμέτρων, λεπτομέρειες βοηθητικού μενού, και μη ειδικοί μπορούν επίσης να ξεκινήσουν γρήγορα.

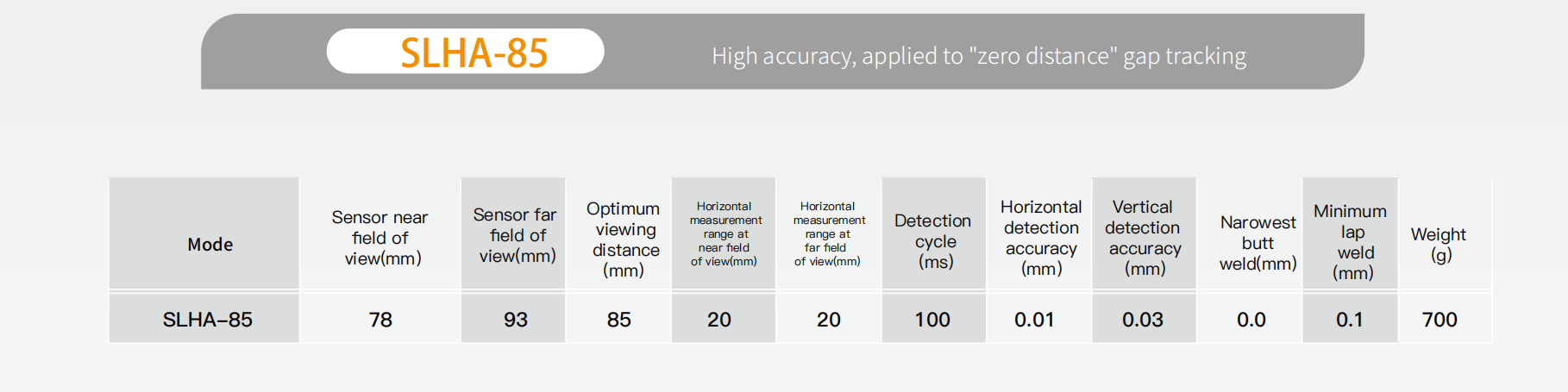

*Η ανίχνευση μηδενικής χάσης αναφέρεται σε αισθητήρες που είναι έξοισον αυτού του χαρακτηριστικού, οι οποίοι μπορούν να χρησιμοποιηθούν για να αναγνωρίζουν χάσεις κάτω από 0,1mm.

*Η απόσταση θέαςς είναι μόνο για σύγκριση και μπορεί να επιπλέον να επιπλέον αναλογιστεί βάσει των συγκεκριμένων αναγκών των χρηστών.

Ο αισθητήρας είναι κατάλληλος για τις πιο απαιτητικές εφαρμογές, καθώς είναι ανεπιδράστης στο ξενικό φως, το νερό και τον κονιορτό (IP67) και ανοσός στην ηλεκτρομαγνητική ακτινοβολία (EMC).

Με Δυνατή Λειτουργία.

01. τροποποίηση θέσης και διόρθωση αποκλίσεων

Η λειτουργία τροποποίησης θέσης και διόρθωσης αποκλίσεων χρησιμοποιείται για ευέλικτα σενάρια συρραφής διαφορετικών κομματιών με τον ίδιο τύπο αλλά με μη συνεπείς ανοχές. Αυτή η λειτουργία εξασφαλίζει ότι δεν απαιτείται καμιά χειροκίνητη παρέμβαση κατά την αλλαγή των κομματιών και ο ρομπότ ενοδεύεται από το σύστημα τροποποίησης θέσης και διόρθωσης αποκλίσεων για να επιτύχει ακριβή συρραφή.

Δύο-σημειακή θέσηση που είναι κατάλληλη για ευθείες συρραφές 2D με αποκλίσεις.

Πολυσημειωτική Θέση Αντίστοιχη για πολυσημειωτικά 2d επιβλέψεις συνδέσεων κολλώνωσης

Θέση Σημείου Αντίστοιχη για πολυσημειωτικές 3d επιβλέψεις συνδέσεων κολλώνωσης.

02 Πραγματικός Χρόνος Ακολουθίας

Η λειτουργία ακολουθίας σε πραγματικό χρόνο χρησιμοποιείται σε σενάρια κολλώνωσης που απαιτούν υψηλή αποδοτικότητα και χωρίς διαταραχή του χώρου. Ο αισθητήρας είναι σταθερός σε σχέση με το φωτιάδι κολλώνωσης, και το φωτιάδι κολλώνωσης αυτοματικά συναρμολογεί τον δρόμο κολλώνωσης βάσει των 3D συντεταγμένων δεδομένων.

03. Σάρωση και Αυτόματη Κολλώνωση

Η λειτουργία σάρωσης και αυτόματης κολλώνωσης επιτρέπει στον αισθητήρα να συλλέξει πρώτα γεωμετρική πληροφορία των συνδέσεων κολλώνωσης. Αυτή η λειτουργία είναι αντίστοιχη για υψηλά ανακατευθύνοντα, στενά χώρη κολλώνωσης και πολυπλοκά σενάρια κολλώνωσης.

Ακολουθία Στιγμιαίων Συνδέσεων Λέιζερ

Η Ακολουθία Στιγμιαίων Συνδέσεων Λέιζερ μπορεί να ανιχνεύσει αποκλίσεις συνδέσεων κολλώνωσης υψηλά, χαμηλά και αριστερά και δεξιά.

Μπορεί να ανιχνεύσει συνδέσεις κολλώνωσης συνδυασμού με μικρά χάρακα.

Λύει το πρόβλημα της ακολουθίας συνδέσεων κολλώνωσης για λεπτές πλάκες συνδυασμού.

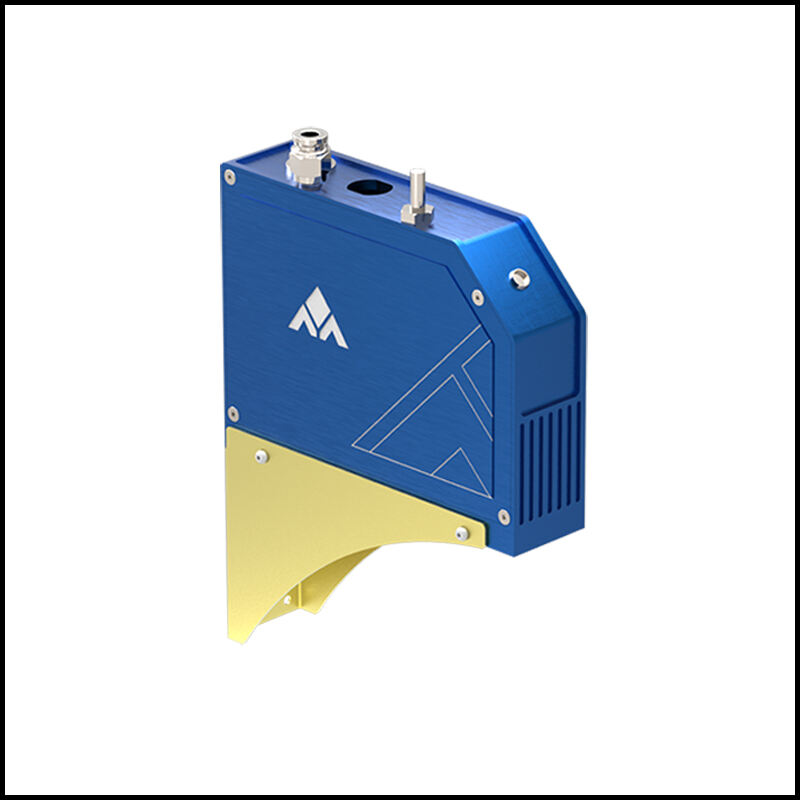

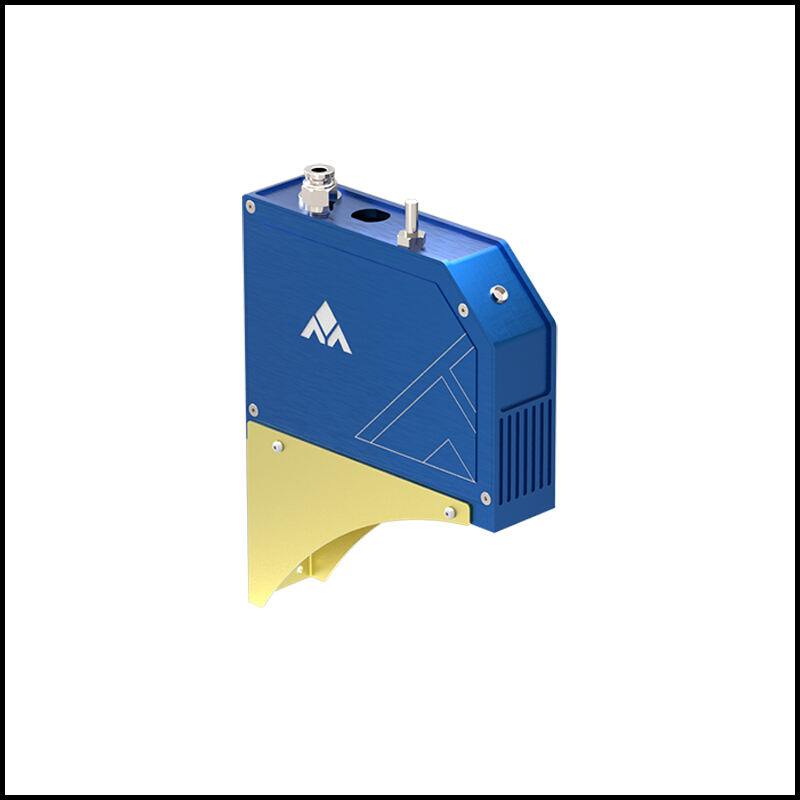

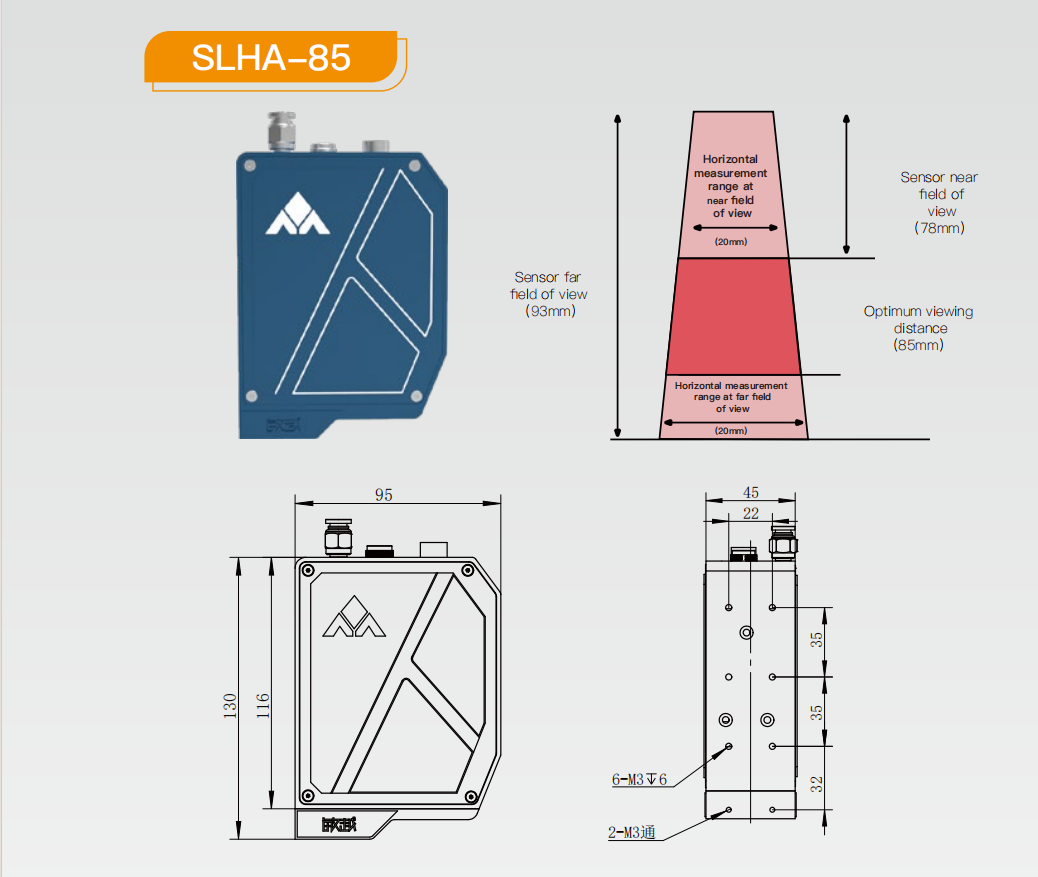

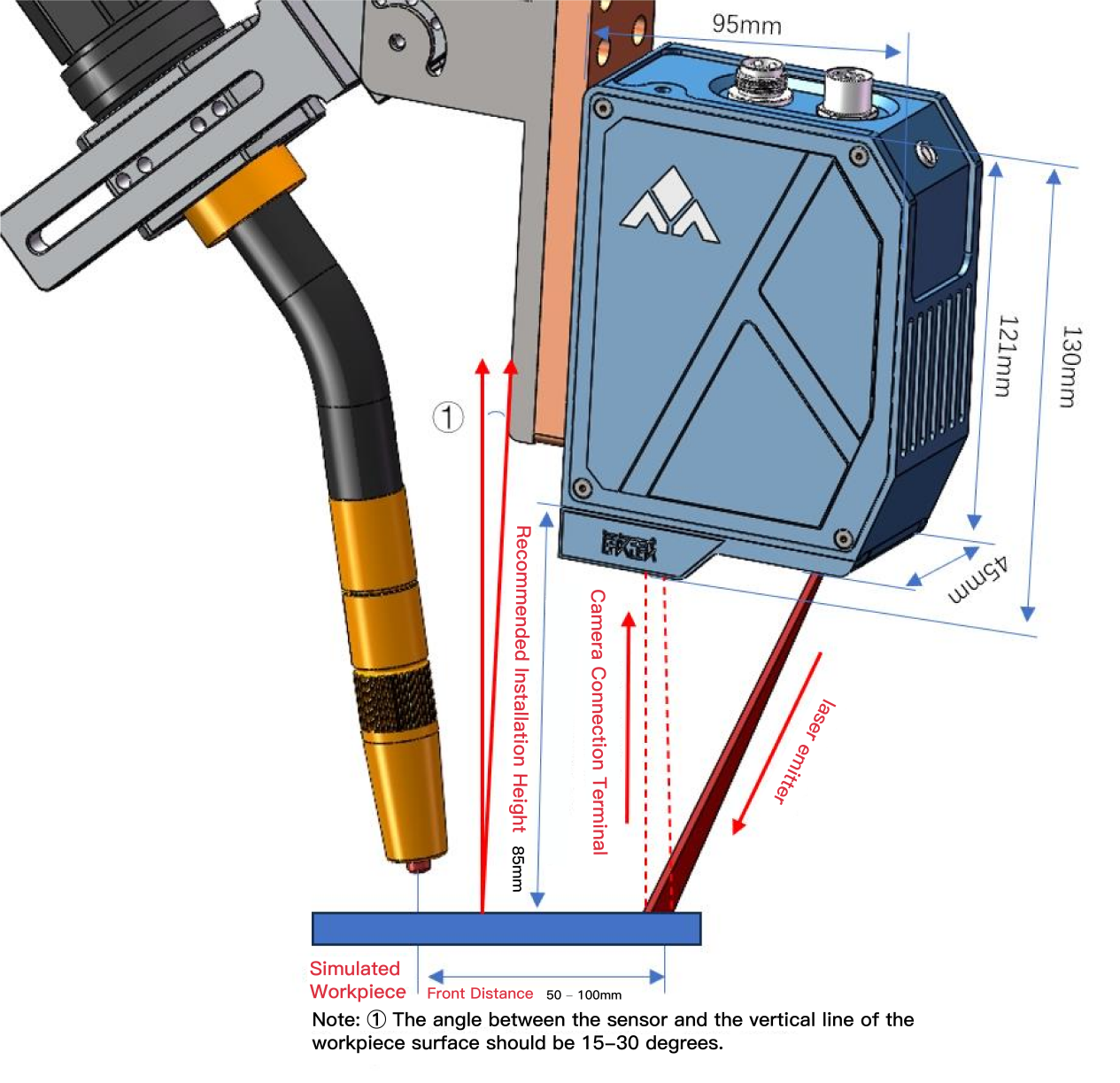

Η καλύτερη απόσταση παρατήρησης είναι περίπου 85 mm.

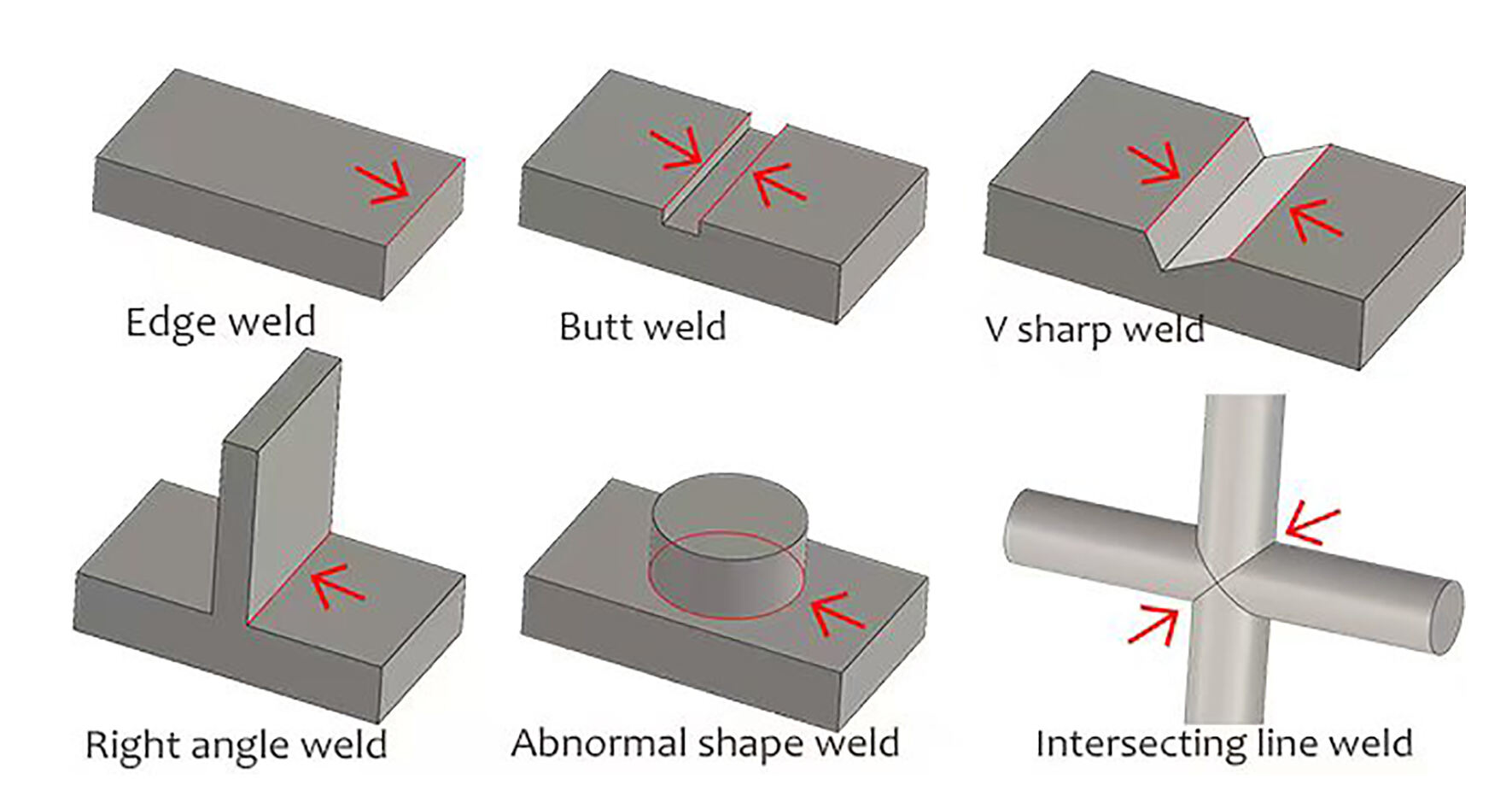

Τύπος ψαλιδισμού υποστήριξης

Ψαλίδι V-μορφής

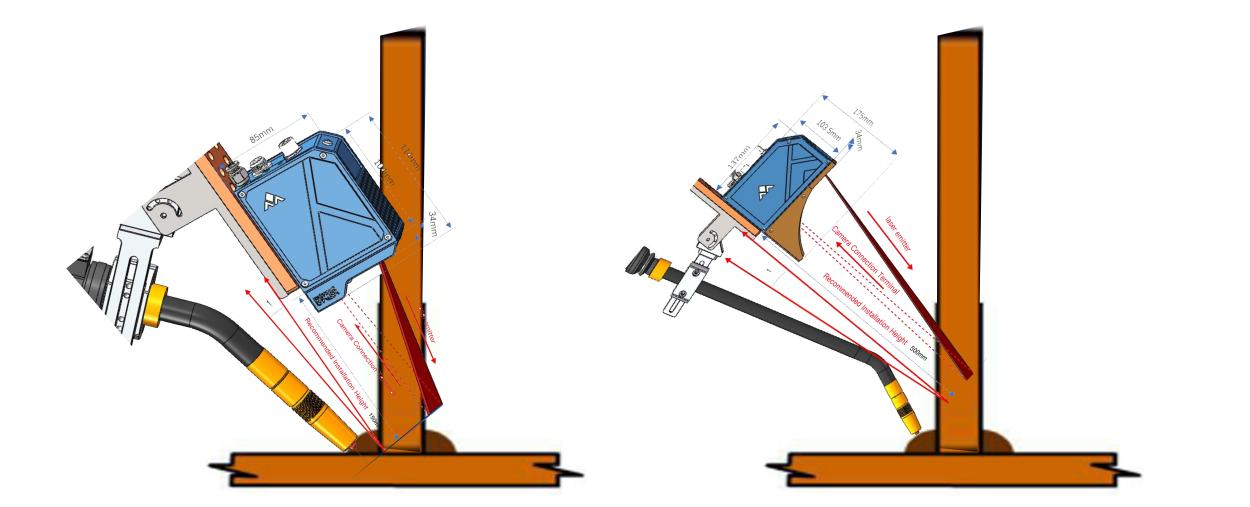

Ψαλίδι γωνίας

Ψαλίδι κάλυψης

Ψαλίδι σύνδεσης

Ψαλίδια διπλού επιπέδου, κλπ.

Υψηλή ακρίβεια, συνδεσμοί μηδέν πτέρου. Επιτρέπεται για βιομηχανία συνδεσμού ανθρακιού χάλυβα.

Με γαλάζιο λέιζερ φως για υψηλή αντανάκλαση φωτός και λαμπρό περιβάλλον. Ειδικά σχεδιασμένο για την συμβολή λέιζερ σε υλικά αλουμινίου κατά τη διάρκεια της εξέλιξης της προσφυγής.

Επιλέξτε τον τύπο λογικά σύμφωνα με το πραγματικό όγκο εφαρμογής, για να αποφευχθεί η σύγκρουση του κομματιού με τον αισθητήρα, η φορτίαση του ρομπότ συνήθως χρειάζεται 20KG.

Συνεργατικός Εταίρος

Υποστήριξη μάρκας ρομπότ

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK