Eine robotische Schweißzelle besteht aus mehreren Komponenten, die miteinander interagieren, um den Schweißprozess durchzuführen. Der erste Bestandteil ist der Roboter. Der Roboter ist ein mechanischer Arm, der das gesamte Schweißen übernimmt. Er ist an einen Computer angeschlossen, der ihm sagt, wohin er gehen und wie er sich bewegen soll. Am Ende des Robotersarms befindet sich ein Schweißwerkzeug, das es ihm ermöglicht, die Metallteile zusammenzuschweißen.

Unternehmen nutzen robotergesteuerte Schweißzellen, um Fabriken schneller und effizienter zu machen. Ein schöner Aspekt dabei ist, dass sie pausenlos Vollzeit arbeiten können. Das bedeutet, sie können die Produkte schneller herstellen als menschliche Arbeiter. Diese Anlage verfügt über mehrere Roboter, die ununterbrochen arbeiten können, während Menschen schlafen oder eine Pause brauchen, was während der Produktionszeit entscheidend ist.

In Bezug auf Genauigkeit sind robotergesteuerte Schweißzellen außerordentlich zuverlässig. Sie werden nicht müde wie Menschen, daher können sie über längere Zeiträume hinweg fehlerfrei arbeiten. Es gibt eine solche Konsistenz.

Robotergesteuerte Schweißzellen verbessern neben der Optimierung von Fabrikoperationen auch die Kosten. Sie helfen dabei, Arbeitskosten zu senken, da sie ohne menschliche Arbeiter operieren können. Für Unternehmen wie Hersteller sind Arbeitskosten

Es gibt viele verschiedene Arten von robotergesteuerten Schweißzellen bei Minyue auszuwählen. Sie kommen in einer Vielzahl von Größen, von kleinen Maschinen, die kleine Projekte bewältigen können, bis hin zu großen Maschinen, die für große Aufgaben zuständig sind.

Leistungsstarke Schweißroboter mit Frontladung, Seitladung, umgekehrter Ladung, Gantry-Montage, intelligente Trajektorienplanung für mehrere Roboter, mehrere externe Achsen und Positionierer zur kooperativen Arbeit. Realisierung der Roboterbewegungssimulation, Kollisionsdetektion, Singularitätsvermeidung und Achsengrenzdetektion.

Schnell, genau, vollständig programmlos, hohe Effizienz und Präzision. Es löst das komplizierte Lehrlauf-Prozess der traditionellen Roboter und spart die Downtime des Lehrlaufs.

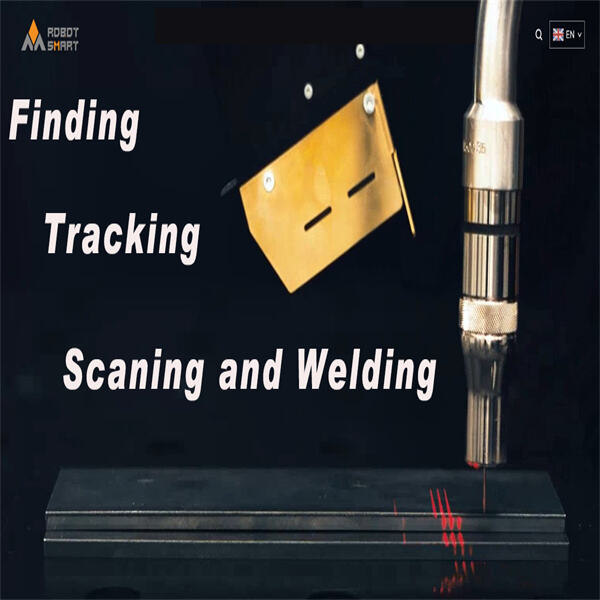

Einsatz der Funktionen zum Suchen und Verfolgen, Scannen der Schweissnaht, Bestätigen der Position und Information der Schweissnaht, Korrigieren der Position der Schweissnaht zwischen dem 3D-Digitalmodell und dem tatsächlichen Werkstück und Lösung des Problems der verschobenen Schweissnaht aufgrund von Materialfehlern und thermischer Deformation.

Beijing Minyue Technology Co.,LTD, als weltweit führendes innovatives Unternehmen für die nicht unterweisungsbasierte intelligente Anwendung von Industrierobotern. Wir spezialisieren uns auf flexible intelligente Fertigung mit unserem selbst entwickelten RobotSmart - Intelligenter Entscheidungssystem, SmartVision - Stereobildstrukturlicht-Visionssystem und SmartEye - Laser-Vision-Nahtverfolgungssystem. Wir bieten eine neue Generation intelligenter Roboterschweiß- und -schneidlösungen.