Technology is advancing rapidly in this fast-paced world. And there are also inventions that change the way we live, change the way we work. However, one of the latest inventions that are helping out is 3D camera technology. These special cameras can take two-dimensional pictures, however three-dimensional pictures, which look more actual. Unlike 2D cameras, 3D cameras generate images that take certain dimensions into account, making you feel that you are observing the item in real life.

3D cameras have largely been the toast of many professions over the years. But you know, they are in use everywhere, from factories and construction sites to the automotive industry — that's all the car-making stuff. MINYUE 3d camera is a three-dimensional representation of a photo that would extract a very high-definition and accurate 3D image while capturing the essence of a photo (or video, depending on your data). This capability enhances the efficiency and velocity of enterprise operation. 3D cameras allow workers to see everything in more detail and make important decisions for their products and projects.

With 3D cameras, businesses have greater accuracy and precision in the way they function. In factories, for example, workers examine products as they are being manufactured with 3D cameras. This process allows them to check that everything's built properly and to spec. This helps the confirming machines, companies avoid mistakes and really get the quality of the products they are getting. That way, customers know they are receiving the highest quality goods.

Even 3D cameras play a critical role in many workplaces. MINYUE 3d machine vision camera are employed for several tasks such as quality checking of products, estimating new items, and inspecting goods before being sent to its destination. In an age where companies are in a hurry to get their jobs done, these cameras make life easier. By capturing clear three-dimension images, companies can pinpoint areas that need improvement. This means that they can discover ways to help improve their processes to be better and more effective.

3D Cameras — What is the great thing about working with 3D Cameras? This gives businesses clear and prompt data, and allows them to make effective decisions in no time. This gives them less time to waste on unproductive activities, boosts their productivity, and in the long run saves them money. If their production line picks up a problem quickly, through a MINYUE 3d vision camera, they can address the issue immediately. This quick response can greatly affect how smoothly the company operates.

There are just countless 3D camera applications across various industries. They can aid the creation of detailed models and prototypes, early examples of products. They can even be used for virtual inspections in which a worker can check items without having to be on-site. With technology growing better and better, and more sophisticated, the potential uses for MINYUE 3d laser triangulation in the workplace are only going to expand.

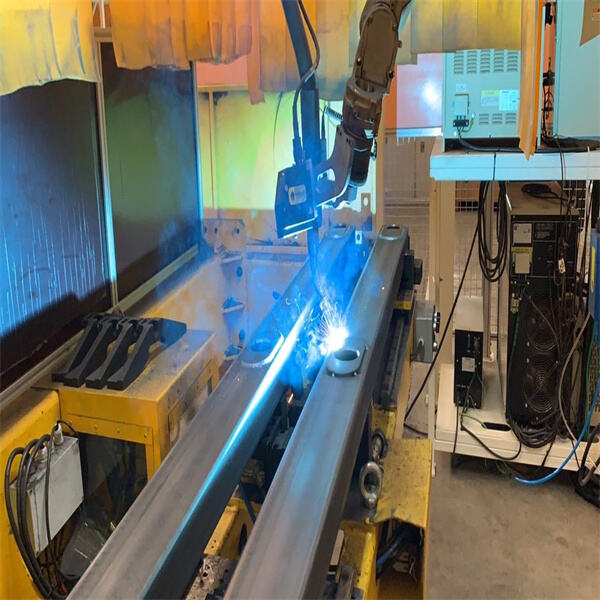

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

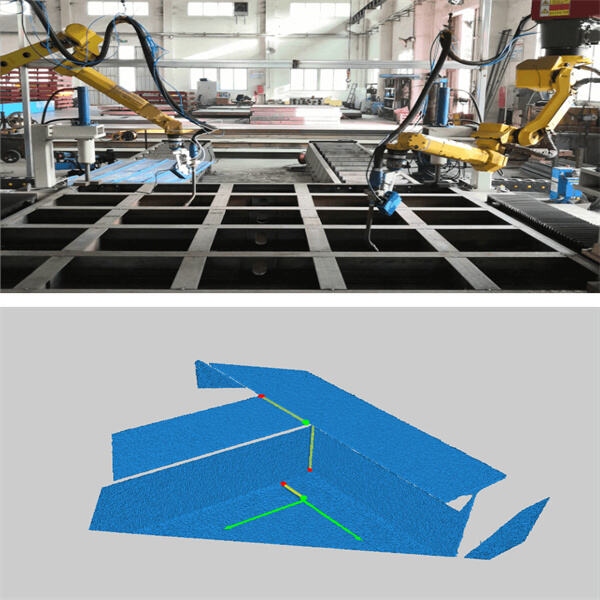

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.