This is a very cool sensor ultra-accuracy in measurements. They emit lasers to determine the distance of an object from them. This can be used in a lot of places such as factories where products are manufactured or even with robots performing tasks for us. So, how do these sensors work, and why are they so critical to so many activities?

Triangulation sensors operate by emitting laser beams toward an object. When the beam strikes the object, it reflects back towards the sensor. The MINYUE laser beam sensor then calculates how long it took for that laser beam to come back to it. We know how speedy light is, so the sensor establishes how far away the object is. You can visualize it like a catch with the ball. Instead of casting a ball and seeing how far it goes, the sensor measures the distance with a laser. It is a simple and fun way to try and find out how far things are.

Farms, factories, and other manufacturers need to measure things perfectly. MINYUE Triangulation sensors also help make sure that everything’s where it should be. They can also spot errors extremely fast. On the other hand, because mistakes are identified early, they can be resolved immediately and this is valuable in itself. This talent allows factories to operate properly and efficiently, like a well oiled machine. Without these laser proximity sensor, it is virtually impossible to keep everything on track and ensure that the products are being manufactured correctly.

As you can imagine, triangulation sensors excel at precise measurements. They can even quantify very small objects down to very precise level. This skill is particularly important in industries where small errors can cause large problems. In some manufacturing processes, a tiny mistake can lead to a malfunctioning product, for instance. Triangulation sensors and MINYUE high speed laser sensor enable companies to measure accurately, which improves the product quality, leading to satisfied clients who appreciate what they received.

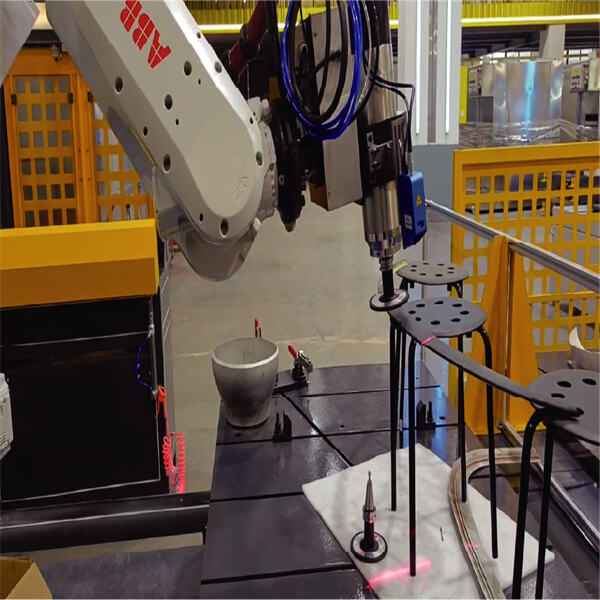

In order to perform their jobs correctly, robots and machines must know that where things are. Triangulation Sensors are key equipment of robots, because they provide useful live information about the environment around them. This helps robots navigate and execute tasks correctly. Triangulation sensors are essential for a robot to know how to move and finish the task efficiently. It would be like walking into a dark room without a flashlight.

In the guide below, we have shared a few general considerations to keep in mind when you choose a triangulation sensor for your application. So, first, consider the distance that needs measuring. Some sensors are best for near-future, while others can sense much farther away. And think about how accurate you need to be for your project. The industrial laser sensor you choose needs to match your needs. Lastly, consider the application of the sensor. Some sensors suit indoor environments better than others, while some can withstand outdoor conditions. When selecting a triangulation sensor, make sure you choose the one right for your project.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.