Structured light 3D cameras are interesting devices that allow us to perceive and measure objects around us in a different and unique way. They work by using light to build complex 3D images of items, making them incredibly useful across many fields, including factories, healthcare and robotics. Let’s take a closer look at how they function, and also how critical they are.

3D structured light cameras work by projecting light patterns onto the target object. As the light shines on the object, it casts shadows and reflections. Which the camera catches, these shadows and reflections. By seeing how these patterns shift on the object’s surface, the camera can build up a 3d camera model of the object. It’s sort of like taking a picture with a magic flashlight that shows you all the bumps, curves and details of an object. It helps gives us a clear idea of how big, how small, the shape of things.

In the factories, accurate measurements are critical to ensuring proper assembly. And this can be achieved with the help of a structured light 3d camera industrial, which allows fast and accurate measurements of objects. For instance, they can verify whether the components of a machine are matching and whether or not a product is the right shape and size. This is helpful to make sure everything is especially built right and works well. These cameras help save time and ensure productivity for workers, which is important in fast-paced factory environments.

Quality control is a process that ensures that things are produced the correct way. Well, it is imperative for companies to provide quality things. Structured light 3d vision camera are amazing for quality control, as they can detect minute details that the human eye may not pick up on. For instance, they can find small imperfections or dents on the surface of a product that may pose issues down the line. This capability can allow companies to deliver superior products and maintain customer satisfaction. In this way, enhanced product perfection and work efficiency, resulting in greater customer satisfaction and more sales, are made possible in collaboration with MINYUE measurement.

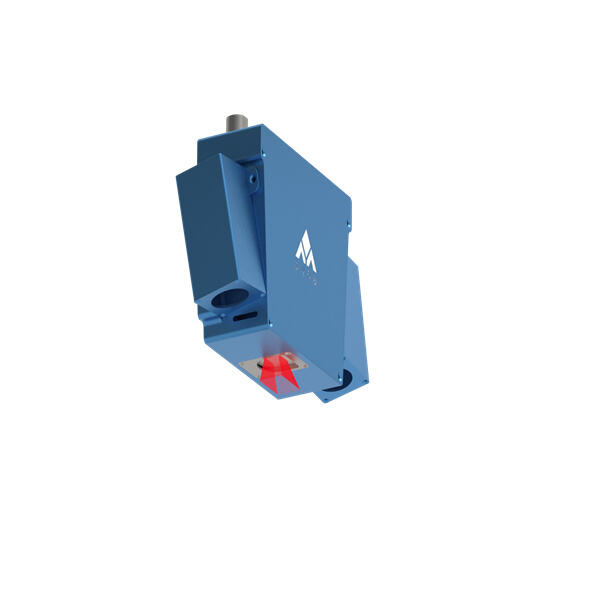

Robots make the most incredible machines that can perform various functions ranging from product assemblies to surgical work. It can greatly enable robots better "see" the surrounding environment using structured light 3D cameras. A robot with one of these cameras attached is able to know how far objects are away and how to pick them up safely, for instance,” he continues. With these advancements, robots are far more useful in factories, hospitals and even in homes. Through the integrated algorithms used with their structured light 3d machine vision camera, MINYUE can make robots smarter and more useful so that they can help improve the lives of humans in a variety of different ways.

At hospitals, doctors use special cameras to peer inside our bodies to see how healthy we are. Structured light 3D cameras can enhance these images, ensuring they are clearer and more detailed — something all the more important for doctors when trying to identify health issues. These cameras allow doctors to notice problems early, when better interventions are possible. Structured light 3D cameras can also enhance virtual reality. Of course, virtual reality is not just for fun, but also has great potential for practical applications, and with MINYUE's advanced technology, the future of medical imaging and virtual reality is bright.

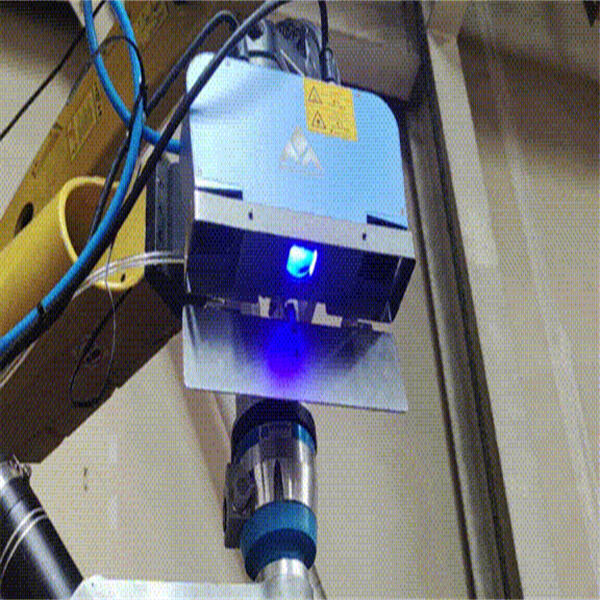

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

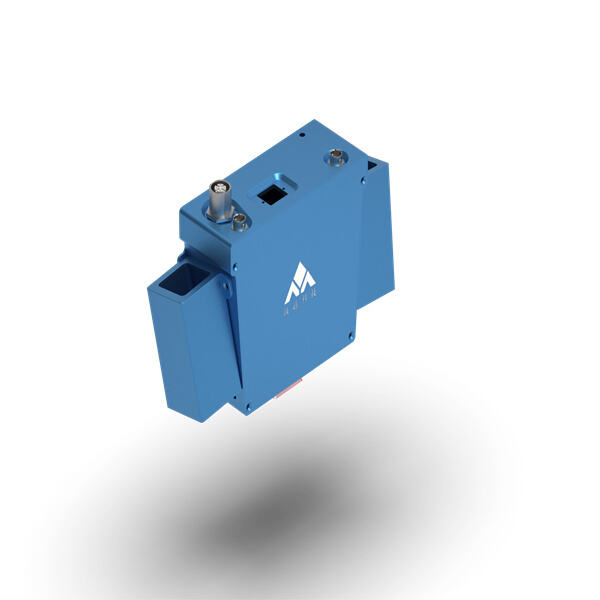

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.