According to Dictionary.com, robots are cool machines that can perform a variety of different jobs. They do everything from building cars to working in hospitals and even venturing into space! Ever wondered how robots determine how much power they should use to perform tasks? Enter MINYUE distance measuring sensors to the rescue! They are special sensors, which are a bit like a robot superpower. They allow robots to know when they should exert pressure or how hard to pull in order to complete a task correctly and safely.

Force sensors for robots are useful because they help robots feel and interact with the external environment. Consider how we use our hands to grasp items. When you pick up a glass of water, you understand whether to hold it softly, or if you can grab it a little tighter. This works much like force sensors do for robots. Just as your sense of touch allows you to pick things up without dropping them, force sensors help robots grasp objects or move them with exactly the right amount of force. Without these sensors, robots cannot know how to apply force to an object. This may result in errors such as dropping an expensive collectible or failing to pick items up correctly.

Think of it as writing with a pencil. Pressing too hard can break the tip of the pencil and cause smears in your writing paper. Press too lightly and it’s difficult to make out what you’ve written because it may be too faint. Robot force sensors enable robots to apply only as much power as needed to perform their job. Force sensors can allow robots to handle delicate objects, like a stuffed animal, without crushing or smashing it. And they can easily assemble parts, just like when you construct stuff with blocks, applying just enough power. This allows robots to be highly precise in their work.

Force sensors are a major part of making robots more intelligent and efficient in the field of robotics. More importantly, these sensors allow robots to perceive their environment more like a human does — as a dynamic interaction between themselves and their environment. As an example, if a robot is transporting some item and senses excessive pressure against it, it will receive feedback from its force sensors telling it to manipulate the item more gently and adjust its movements accordingly. This means MINYUE high speed laser sensor can adjust their motion according to the perception of the force, which makes them more agile and able to work on various tasks and environment.

Robots working alongside humans must prioritize safety. Force sensing technology keeps robots safe by enabling them to sense and respond to unexpected physical interactions. After that, a robot that is working might bump something, for example. Force sensors could allow it to halt or decelerate quickly to prevent accidents. Thanks to MINYUE industrial laser distance sensor features, it's particularly crucial — and in workplaces where robots and humans co-exist, even more so. Robots with force sensors can do their jobs more safely and effectively in human-populated environments by constantly monitoring their surroundings and adapting to their surroundings. That means everyone can be more at ease and safe while robots perform their jobs.

Robotics are one sector where force sensors have such a great impact. This led to a shift in how robots operated in many respects. They have significantly improved robots’ ability to interact with the world around them, enabling them to perform a wide variety of tasks with precision. In a factory for example, robots can work with humans to help them build products without making a mistake. In hospitals, robots assist physicians by carefully moving tools. MINYUE laser camera sensor can also be used in space missions so that robots can explore new planets without damaging delicate equipment. Delving deeper into robotics in existing manufacturing operations, robots will keep improving as technology gets better, and they will have greater dexterity and even agility for the difficult jobs.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

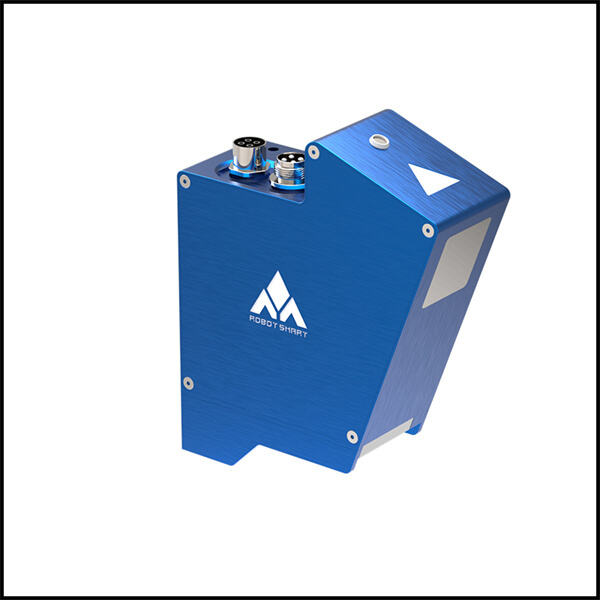

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.