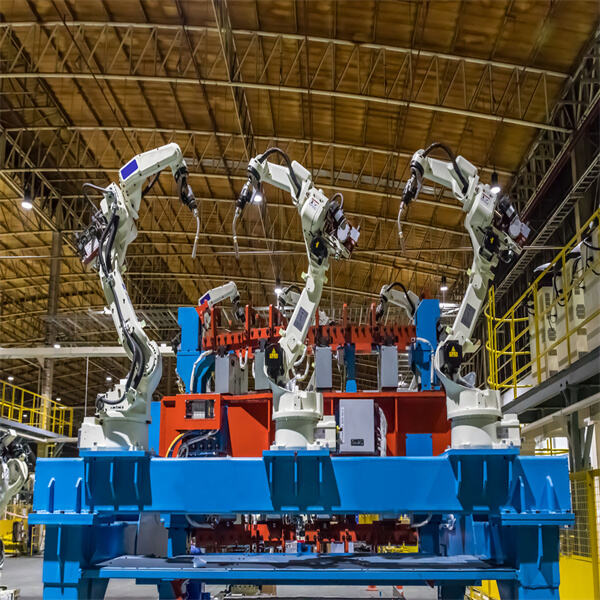

Automated robotic welding machines are super awesome machines that assist in the assembly of materials in plants. These are like real transforming robots as they can very much combine metal parts together themselves, without a single human helping. 606 information style Today, we are going to examine this MINYUE automated robotic welding that is bringing a revolution and changing the factory model all around the world In terms of production. We will explain what they do, why they are important, and how they make work safer and quicker.

Automated robotic welding systems are the superheroes of factory land. They spent hours and hours, day and night, welding metal parts together to make popular things like automobiles, aircraft, and all sorts of toys little children like. These are very precise robots, which means they can be used to weld with incredible precision. So every piece fits perfectly every time. The products produced with these robots are typically of high quality because their precision.

Factory use of automated robotic welding systems offer oodles of advantages. First of all, these robots are very, very fast. They can operate a lot faster than humans can. This speed means that factories can produce items more quickly and deliver them to stores more quickly for people to purchase. This is extremely important as it is a way to cater the needs of customers who require products on time. This MINYUE automatic welding robot is not only faster, but also less error-prone than humans. This ensures that whatever they produce is always top notch, which is good for customers.

Welding is an unsafe workplaceHands on tasks like welding can be dangerous for people. Sparks are flying everywhere, and flames can be very hot and dangerous. However, the safety before automated robotic welding systems is far better for anyone. This MINYUE automated welding robot does not tire in the same way people do and therefore can work without breaks. They also never become distracted or make mistakes. This means when robots are welding, accidents in factories are far less likely. Ensuring that workers stay safe is critical, and these robots play a big part in that.

Robotic systems made possible by computers are leading the way to a very much brighter future for welding. And the better technology becomes, the better the robots will get at the job. They will be faster and more precise, and they will be safer than before. These better robots will enable factories to make even more wonderful things in the future. There will be more chances for human beings to work alongside these machines in a way that keeps them safe.

One of the most significant advantages of robotic automated welding in factories is that it can save companies money and time. Since they can operate quickly and effectively, factories can manufacture more goods in a shorter period of time. When factories can produce more things, faster, companies can sell more products and make more money. It enables companies to grow, and that is beneficial for them. In addition, these robots never take time off, vacation time or breaks. They can work tirelessly, and that keeps things going consistently.

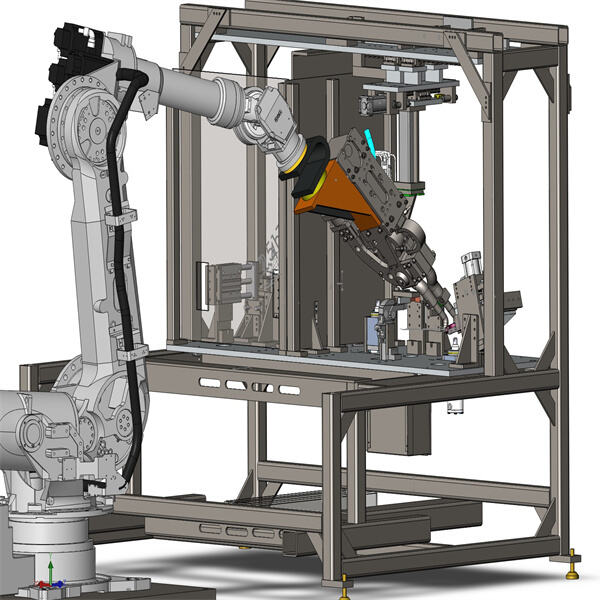

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.