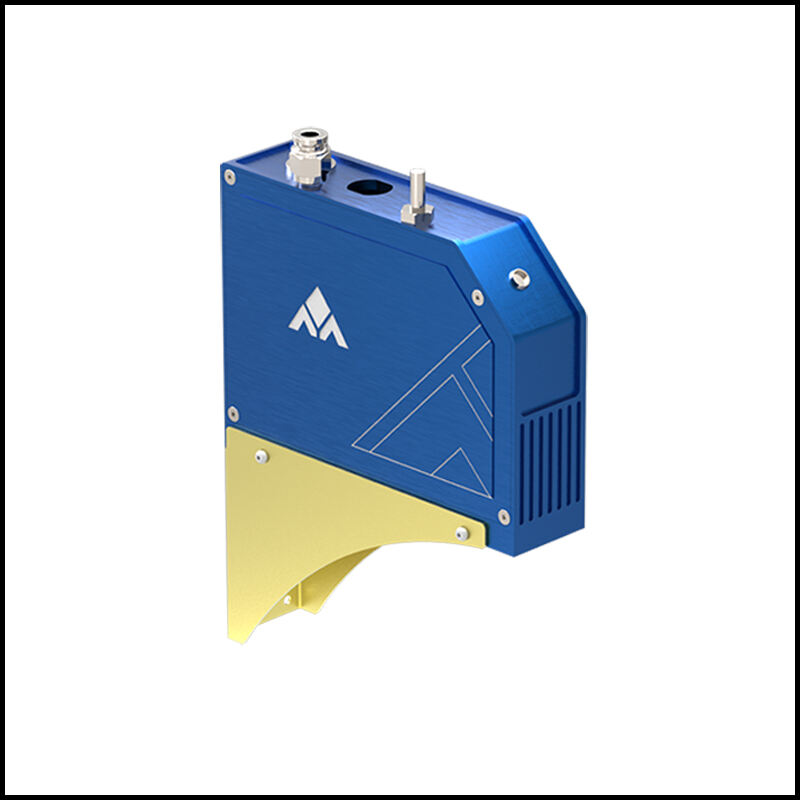

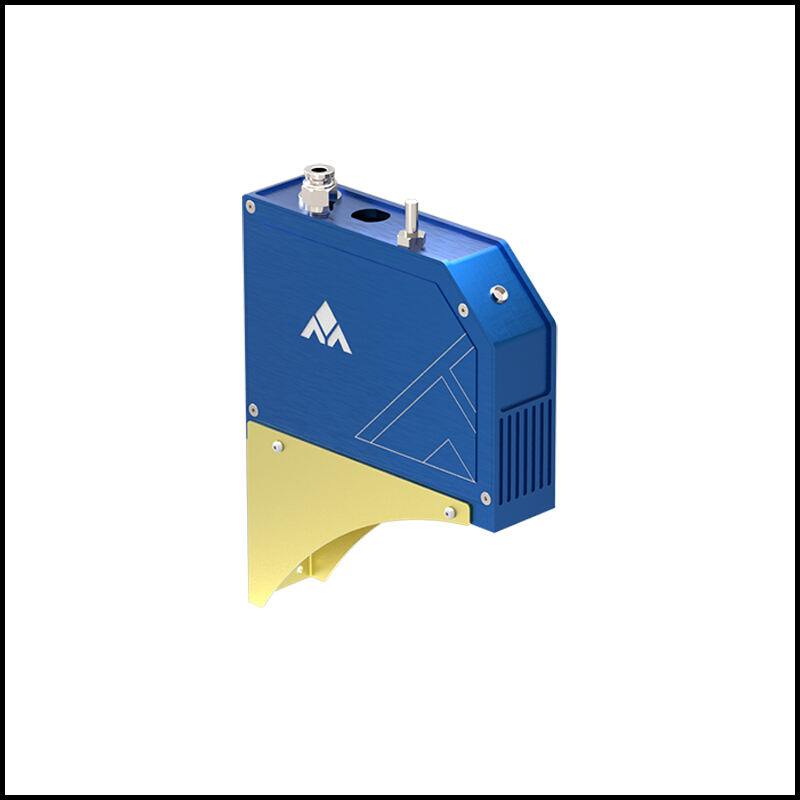

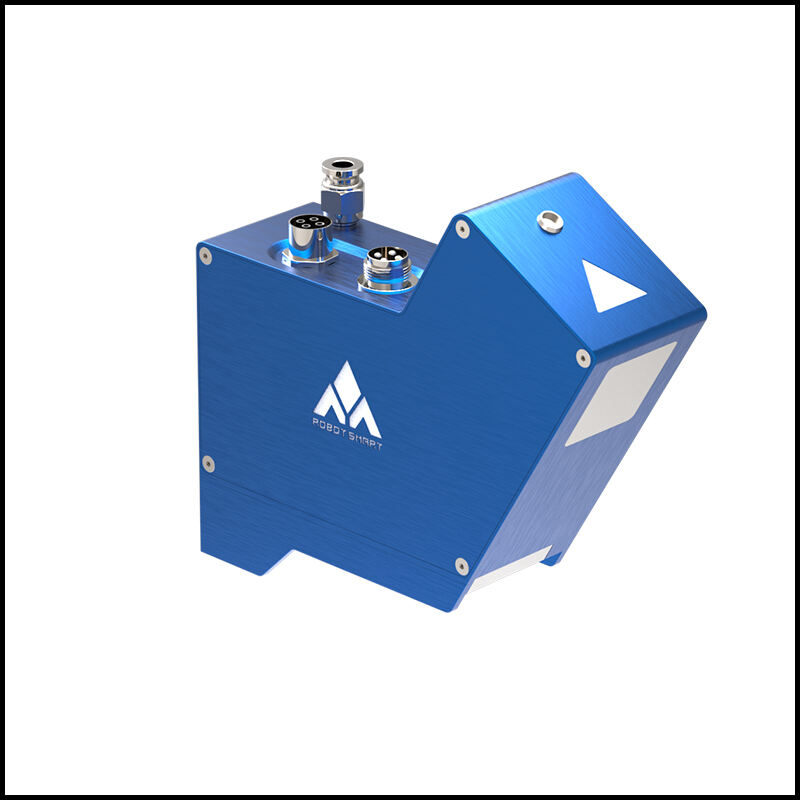

SmartVision 3D binokulêre visie kamera

SmartVision 3D binokulêre gestruktureerde ligvisiestelsel

- Oorsig

SmartVision 3D binokulêre visie kamera

Verskaf brein en oë aan robot.

Produk Model

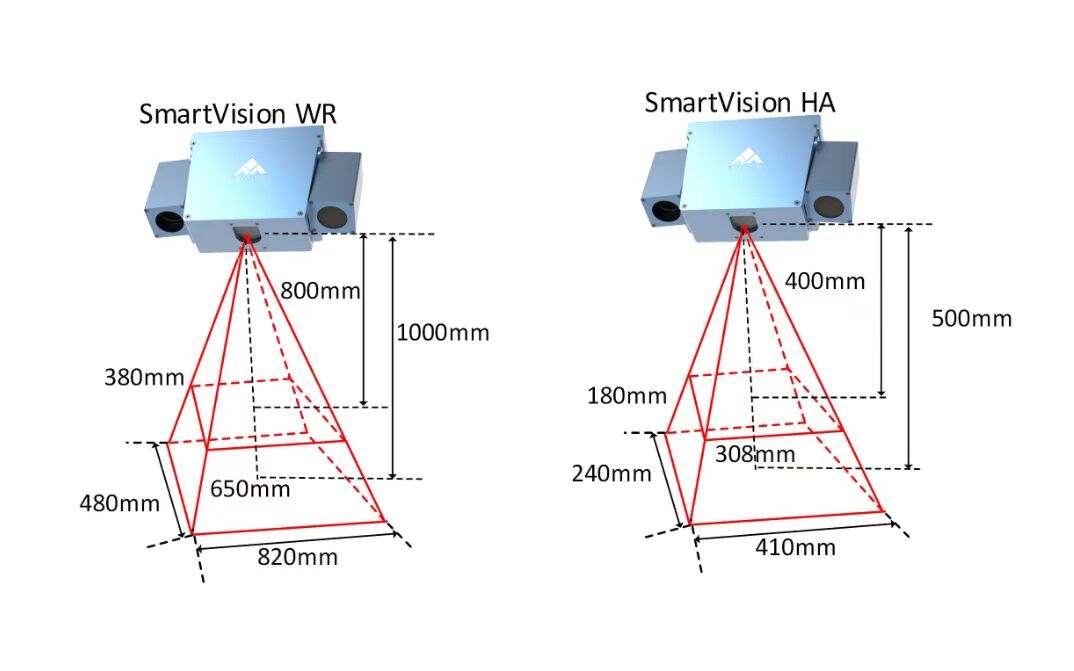

SmartVison reeks produkte is verkyker gestruktureerde lig visie sensors ontwikkel deur Minyue Technology vir industriële robot sweis en sny toepassings. Daar is twee algemene modelle SmartVison WR en hoë-presisie SmartVision HA hang af van akkuraatheid en omvang.

Hoofparameter

| PROJEK Nommer | parameter | SmartVison WR |

| 1 | Bedryfsafstand (mm) | 800-1000 |

| 2 | Naby gesigsveld (mm) | 650*380 |

| 3 | Verre gesigsveld (mm) | 820*480 |

| 4 | Resolusie (Pix) | 1624*1240 |

| 5 | Pixel (MP) | 2 |

| 6 | Meting akkuraatheid (mm) | 0.5 |

| 7 | Kalibrasie akkuraatheid (mm) | 0.03 |

| 8 | Insamelingstyd (s) | 1 |

| 9 | Algehele grootte (mm) | 233 * 76 * 121 |

| 10 | Gewig (kg) | 3 |

| 11 | Bedryfstemperatuurbereik (℃) | 0 ~ 45º |

| 12 | Kommunikasie hawe | Gigabit Ethernet-poort |

| 13 | Bedryfspanning (V) | 12 |

| 14 | Beskermingsgraad | IP65 |

Produk eienskappe

1.Dit kan 3D-data van hoë gehalte lewer vir 'n verskeidenheid metaalwerkstukke, wat aan die uiteenlopende vereistes van anti-omgewingslig, hoë akkuraatheid, hoë spoed en klein volume in verskillende versoeke kan voldoen.

2.Kan hoë akkuraatheid, hoë spoed, aanpasbaar wees, die gesigsveld kan aan die werklike behoeftes van tipiese tonele voldoen.

3.Dit integreer 3D-visie, diep leer, bewegingsbeplanning en ander tegnologieë, neem grafika aan sonder programmering wat modulêre sleep-, bedrading-, parameterkonfigurasie- en nie-programmeringsfunksies kan uitvoer.

4.Neem aluminiumlegeringsmateriaal aan, volledig ingeslote dop, beskermingsklas is IP65, 24V bedryfspanning, dit het CEFCCVCCI en RoHS-sertifisering geslaag. Kan stof, vibrasie, vog, elektromagnetiese interferensie en ander moeilike omgewings beter hanteer.

Minyue intelligente produkte

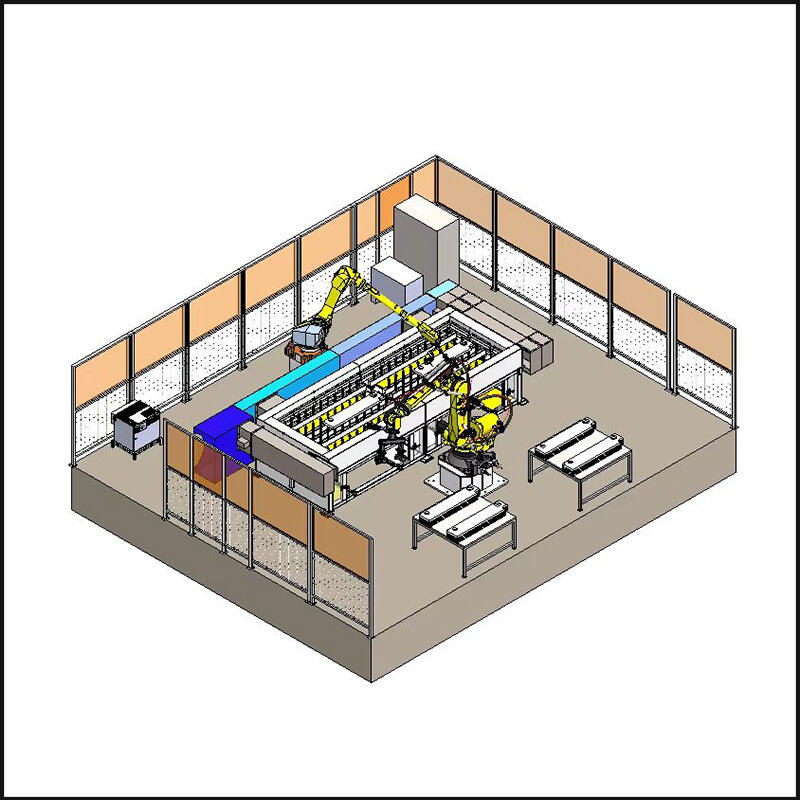

Laser naat opsporingstelsel

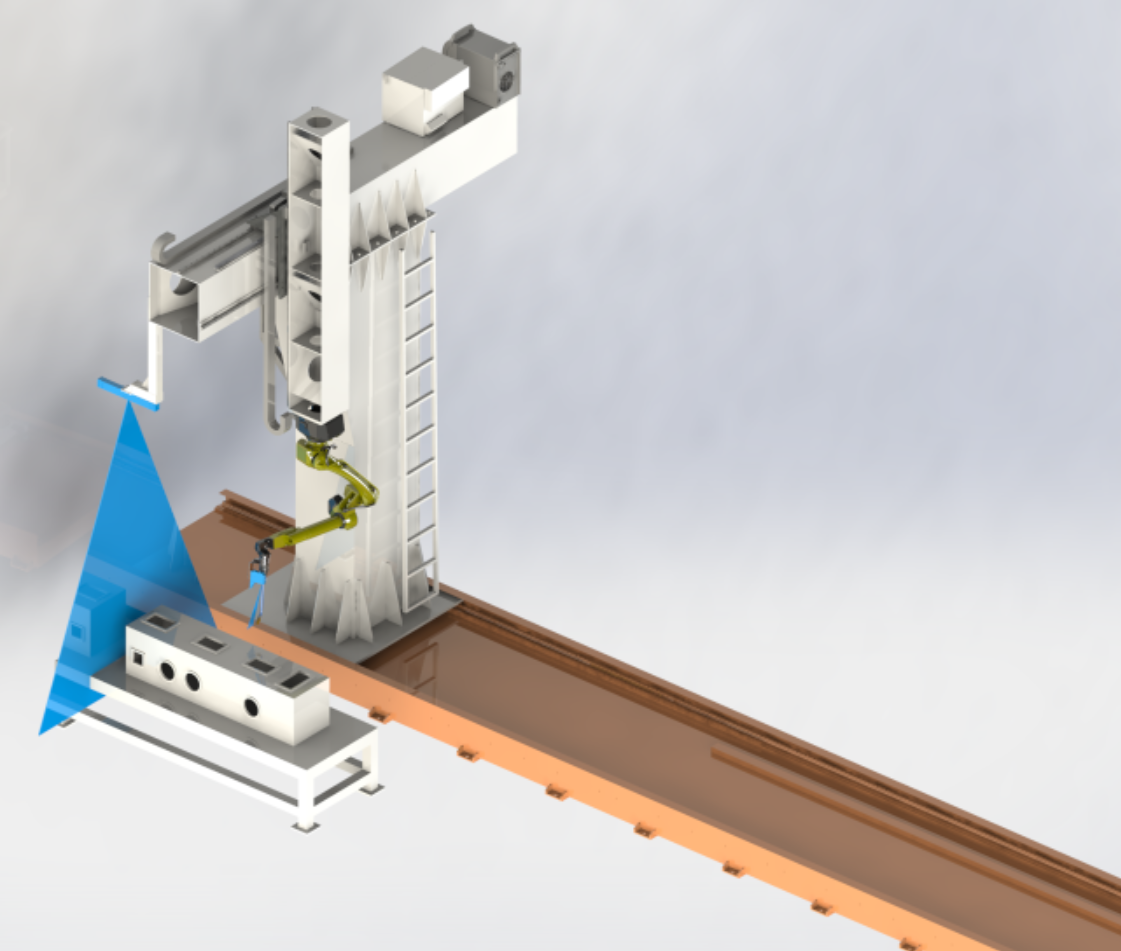

Baie probleme soos slegte sweisomgewing, hoë arbeidsintensiteit, lae sweisdoeltreffendheid en groot verwerkingsfoute het die industriële robotsweisbedryf geteister.Deur SmartEye-lasernaatopsporingstelsel vir identifikasie en posisionering,die probleem van swak konsekwentheid van werkstuk, verwerkingsfout, sweisgroepgaping onreëlmatig op te los, baie daaropvolgende handherstel- en slypwerk verminder, nie net die arbeidsmag bevry nie, maar ook die werkdoeltreffendheid verbeter

Vanlyn programmering sagteware

Met die geleidelike vrystelling van die vraag na multi-variëteit, klein-batch en buigsame produksie, het die mark hoër vereistes vir die gerief van robotprogrammering, en die tradisionele onderrig- en reproduksierobot kon nie in die markvraag voorsien nie.Minyue vanlyn programmeringstelsel -RobotSmart kan vinnig robottrajek genereer, die programmeringsprobleme effektief oplos, soos ingewikkelde sweisbaanonderrig, lae programmeringsdoeltreffendheid en lae robotbenuttingskoers.

1.Minyue-tegnologie ontwikkel onafhanklik kern-lasernaatopsporingstelsel en vanlyn programmeringsagtewareprodukte en kombineer dit met toepassings

2.Die kombinasie van verskeie onafhanklik ontwikkelde produkte kan vinnig kliënte se intelligente toepassingsvereistes verwesenlik

3. Vanlyn programmeringsagteware genereer vinnig trajek, visie om trajek akkuraatheid te verseker, die kombinasie van die twee produkte om "1+1" groter as 2 te bereik

4.Op die oomblik het ons produkte volwasse toepassing in skeepsbou-, waplaat- en ander sweisbedrywe om die intelligente opgradering van robotsweis- en snyvervaardiging te help

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK