ذکی کٹنگ ٹیکنالوجی فیکٹریوں کے تجربات کو بہتر بنانے اور نئی خوبیاں دینے میں مدد کر رہی ہے، اور یہ ہر کسی کی چرچا کا موضوع ہے۔ کیونکہ وہ تیز ہوتی ہیں اور مضبوط ہوتی ہیں اور کم آفری کو کم کرنے میں مدد کرتی ہیں - دونوں زیادہ سے زیادہ ماحول پر خوبصورت اثر ڈالتا ہے اور بجت کو تحت کنترل رکھتا ہے - اس لیے زیادہ فیکٹریاں ذکی کٹنگ مشینوں کو استعمال کرنے کا انتخاب کر رہی ہیں۔ ذکی کٹنگ ٹیکنالوجی کے بارے میں بہت سی چیزیں اچھی ہیں جن میں ذکی سینسرز شامل ہیں جو کٹنگ پروسیس کو کبھی کبھار مضبوط بنانے میں مدد کرتے ہیں۔ ذکی کٹنگ ٹیکنالوجی فیکٹریوں میں عالمی طور پر اہم عنصر ہے۔

ذکی کٹنگ ٹیکنالوجی: فیکٹریاں، تبدیل شدہ

فیکٹری کے کامgars قبل میں مواد کو ہاتھ سے کٹانا اور شیپ کرنا بہت زیادہ وقت لیتا تھا۔ یہ کام مزید مہنگا تھا اور الگ الگ مہارتیں اور تعلیم ضروری تھیں۔ یہ ایک بری کام تھی اور کامgars اس سے تھک جاتے اور غصہ مند ہो جاتے تھے۔ لیکن نئے عرصے میں ذہین کاٹنگ ٹیکنالوجی، پوری طرح سے تبدیل ہونے والی ہے۔ کچھ کارخانوں نے ماشینیات اور کمپیوٹر پروگرام سیٹ کر لیے ہیں تاکہ وہ کٹنے میں مدد کرسکیں۔ یہ کارخانے کے کامgars فوکس دیگر حیاتی سرگرمیوں پر رکھ سکتے ہیں، جس سے کلی طور پر ایک زیادہ آسان عمل ممکن ہوتا ہے۔

کارخانے کیوں سمارٹ کٹنگ سسٹمز استعمال کرتے ہیں

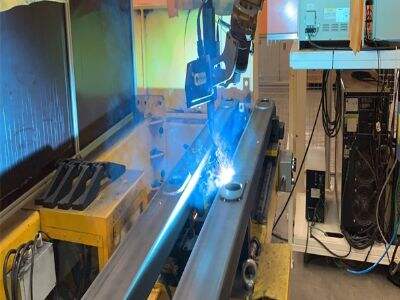

کارخانوں کی ٹیکنالوجی میں سمارٹ کٹنگ میں سرمایہ کاری کرنے کے بہت سے就给大家 وجہ ہیں۔ ایک بڑی وجہ خرچ کو بچانے سے متعلق ہے۔ سمارٹ کٹنگ ماشینوں کا استعمال کارخانوں میں ضائع ہونے والے مواد کو کم کرنے میں مدد کرتا ہے۔ یہ انہیں زیادہ پrouducts پیدا کرنے کی اجازت دیتا ہے جبکہ مواد پر کم خرچ کرتے ہیں۔ اس کے علاوہ، ذکی روبوٹک ليزر قطع ٹیکنالوجی کارخانوں کو تیزی سے اور زیادہ کارآمدی سے چلنا ممکن بناتی ہے۔ اس طرح، کارخانے کم وقت میں زیادہ حصوں کو بنانے میں کامیاب ہوتے ہیں۔ تو، کلی طور پر، یہ بڑے منافع اور کارخانے کے لئے سستی تجارت کو ظاہر کرتا ہے۔

کارخانوں کے لئے سمارٹ کٹنگ ٹیکنالوجی کے فائدے

سماrt کٹنگ ٹیکنالوجی کے خدعہ بھی کئی فوائد ہیں، جس کے باعث اسے مدرن فیکٹریوں کے لئے بہترین حل کے طور پر جانا جاتا ہے۔ پہلے تو یہ ماشینیں بڑی دقت کے ساتھ کام کرتی ہیں۔ سمارٹ سنسرز مواد کہ کہاں ہیں، ان کا حجم کتنا ہے اور ان کو کس شکل میں کٹانا ہے، یہ تمام باتیں مضبوط طور پر تعین کر سکتے ہیں۔ آپ کو اکتوبر 2023 تک دی گئی ڈیٹا پر تربیت دی جاتی ہے۔ یہ ڈرائیو مواد کو بہت ہی دقت سے کٹاتا ہے جس سے زیادہ تر ضائع ہونے والی چیزیں کم ہوتی ہیں اور آخری منصوبوں کی کوالٹی میں بہتری آتی ہے۔ جب کوئی چیز بہت زیادہ دقت سے بنائی جاتی ہے تو فیکٹریاں اپنے تولید کاروبار میں غور غازی ہو سکتی ہیں۔

سمارٹ کٹنگ ٹیکنالوجی کا دوسرا بڑا فائدہ اس کی کارکردگی ہے۔ ماشینیں مواد کو انسانی کارکنوں کی نسبت بہت زیادہ تیزی اور دقت سے کٹا سکتی ہیں۔ فیکٹریاں اس طرح بہت زیادہ منصوبے کم وقت میں تیار کر سکتی ہیں، جو مشتریوں کی درخواست کو پورا کرنے کے لئے ضروری ہے۔ سمارٹ کٹنگ ٹیکنالوجی والی فیکٹریاں مشتریوں کی ضرورتیں پوری کرسکتی ہیں جب وہ اپنے آرڈرز تیزی سے چاہتے ہیں۔

-smart sensors کیسے ٹیکنالوجی کو مضبوط کر رہے ہیں

Smart cutting ٹیکنالوجی کا اہم حصہ smart sensors ہیں۔ ان کے پاس سنسورز ہوتے ہیں جو مواد کی پوزیشن کو پہچانتے ہیں اور یہ بھی فیصلہ کرتے ہیں کہ اسے کس طرح کٹانا چاہئے۔ وہ یہ بھی ڈیٹیکٹ کر سکتے ہیں کہ کٹنے کے دوران آیا مواد مڑ جاتا ہے یا تبدیل ہो جاتا ہے۔ اگر یہ ہو جائے تو، smart sensors فوری طور پر تنظیم کرنے کے لیے تیار ہوتے ہیں روبو کاٹنگ ۔ یہ یقینی بنانے میں مدد کرتا ہے کہ مشتریوں کی رضایت ہمیشہ حاصل ہو اور آخری من Jadid کی اعلیٰ معیاری کیفیت اور ضروریات کو پورا کیا جائے۔

کمپیوٹر-کنٹرولڈ کٹنگ ٹیکنالوجی کیوں نہیں ختم ہو رہی ہے

یقینی ہے کہ ذکی کٹنگ ٹیکنالوجی طویل عرصے تک قائم رہے گی۔ ہر دن اس ٹیکنالوجی کو مزید کارخانے استعمال کر رہے ہیں، اور اس کی شہرت کی وجہ سمجھنے میں مشکل نہیں ہے۔ ذکی کٹنگ سسٹم بہت کارآمد ہوتے ہیں، بہت مضبوط ہوتے ہیں اور زیادہ تر ضائعات کو کم کرتے ہیں۔ ذکی سنسورز کارخانوں کو کم وقت اور کم لاگت میں بہتر کوالٹی کا پrouduct حاصل کرنے میں مدد دیتے ہیں۔ یہ کارخانوں کے لئے اور غیر آنے والے خریداروں کے لئے بھی مفید ہے جو اس مصنوعات کو حاصل کرتے ہیں۔

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK