Kaynak robotları nedir? | Genişleme silindiri | - YouTubeKaynak robotları nedir? | Genişleme silindiri | YouTube Bir insanın tek başına yapabileceği şeyi daha hızlı ve daha iyi yapmak için tasarlanmıştır. Kaynak endüstrisinde bu tür robotları üreten birçok işletmee rağmen, bir ad aydınlıkta parlıyor ve bu ad MINYUE. MINYUE'nin kaynağı robotları devrim yaratan ve sürekli geliştiren en modern teknolojilere sahiptir. robotik nokta kaynaklama sektör

MINYUE kaynak robotları fabrikaları daha önce hiç olmadığı kadar çalışabilecek hale getiriyor. Bu robotlar hızlı ve hassas olmak üzere tasarlanmıştır. Bu da şirketlerin daha az zaman içinde çok daha fazla ürün üretebileceği anlamına gelir. Bu iş dünyası için harika haber! Daha fazla şey yapabilmeleri ve bunu daha hızlı yapabilmeleri, daha fazla para kazanmalarını ve büyüyebilmelerini sağlar. Şirketler, insanların istediklerine yönelik daha fazla ürün sunarak daha fazla para kazanır ve çok başarılı olurlar.

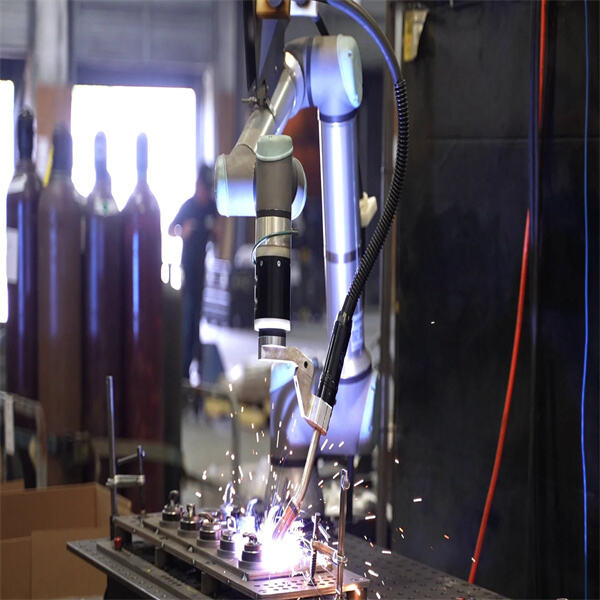

Gerçekte, robotlar işlerin yapıldığı yolunu devrim yaratmaktadır robotik kaynaklama hücre bugün yapılır. O zamanlar eldeki tek seçenek elle kaynaklama ve bu, en iyi durumda zaman alıcı ve yorucu bir işti. Ancak şimdi bu inanılmaz robotik cihazlar, insanlara göre çok daha hızlı ve daha iyi çalışabilir. Robotlar ayrıca, insanlar için tehlikeli olabilecek alanlarda çalışabilen daha güvenli olanlardır. Sıcak malzemeleri taşıyabilir ve küçük alanlarda çalışabilirler. Ve MINYUE, tüm kaynaklama işlemiyle ilgili olarak devrim yaratan öncü bir firma olma konusunda heyecan verici bir değişime önderlik ediyor.

Tehlikeli alanlarda çalışılmasının hızlı bir şekilde arttığı görülmektedir robot kaynak kolu endüstri ve şirketler hızlı bir şekilde gelişmelere uyum sağlamak zorundadır. İşte bu noktada MINYUE ortaya çıkar. Bu nedenle sürekli olarak çeşitli endüstri taleplerine uyacak yeni ve daha iyi kaynak robotları üretmek için çaba gösteriyorlar. Robotları çok yönlüdür ve çeşitli görevlere uygulanabilir, bu da onları herhangi bir kaynak gereksinimi olan işletmeye incredible derecede faydalı kılar. Mobilya yapmaktan arabalara kadar, MINYUE hayal edebileceğiniz her şeyi veri akışlarını oluşturabilir.

Akıllı kaynak robotlarına geri dönelim, bu robotlar üretim oyununu değiştiriyor. Şirketler, MINYUE'in harika makineleri sayesinde kaynak süreçlerini basitleştirebilir. Bu şekilde hataları minimuma indirir ve tüm süreçleri düzenli tutar. Çevrelerinden öğrenen robotlar çeşitli maddeler ve boyutlarda kullanılabilir. Çok yönlülükleri aynı zamanda çeşitli imalat işlerinde bir varlık olmalarını sağlar. Metaller, plastikler ve diğer malzemelerle çalışabilirler, bu da onları birçok endüstride son derece yardımcı kılar.

MINYUE, yüksek kesinlikle çalışabilen en iyi kalite kaynak robotlarının üretimiyle uzmanlaşmıştır. Makineleri en iyi kalite ürünler üretilmesi için tasarlanmıştır. Bu, karmaşık parçalar üretmek zorunda olan veya mükemmel olmak zorunda olan şirketler için çok önemlidir. Yüksek kalite, ürünlerin dayanıklı ve işlevsel olmasını sağlar. Onlara göre, yeni teknikleri öğrenmekte durmadıklarını söylüyorlar. Bu nedenle, MINYUE'nin robotları her zaman kaynağı alanlarında önderlik eder. Bu zeki makineler, kaynağı alanında daha parlak bir gelecek yaratmak için yol açıyor.

Hızlı, doğru, tamamen Programsız, yüksek verimlilik ve yüksek hassasiyet. Geleneksel robotların karmaşık öğretim süreçlerini çözer ve öğretim sürecindeki duruş zamanını tasarruf eder.

Beijing Minyue Technology Co.,LTD, dünyanın önde gelen yüksek teknoloji firmalarından biridir ve endüstri robotlarının öğretimsiz zeka uygulamalarında uzmandır. Kendi geliştirdiğimiz RobotSmart - Zeka Karar Verme Sistemi, SmartVision - Çift Gözlü Yapılandırılmış Işık Görüş Sistemi ve SmartEye - Laser Görüş Duvar İzleme Sistemi ile esnek zeka üretimi üzerine uzmanlaşmıştık. Yeni nesil zeka robot kaynaklama ve kesme çözümleri sunuyoruz.

Güçlü kaynak robotu için ön yükleme, yan yükleme, ters yükleme, konsol montajı, birden fazla robot için zeka yoluyla hareket planlama, birden fazla harici eksen ve konumlandırıcı işbirliği için entegre çalışabilirlik sağlar. Robot hareketi simülasyonunu, çarpışma algılama, tekil nokta önleme ve eksen sınırı algılama gerçekleştirmeyi sağlar.

Bulma ve izleme fonksiyonlarını kullanarak kaynak ekranını tarama, kaynak ekranının konumunu ve bilgilerini doğrulama, 3B dijital model çizimi ile gerçek parça arasındaki kaynak ekranı konumunu düzeltme ve gelen malzeme hataları ve termal deformasyon nedeniyle ortaya çıkan sapmalı kaynağı çözmek için kullanılır.