A soldagem robótica está melhorando a manufatura em vários aspectos. Primeiro, ela é muito mais rápida do que a soldagem manual. Os robôs podem funcionar continuamente, dia e noite, sem a necessidade de pausas. Isso significa que produtos podem ser produzidos tipos de robôs de soldagem

Existem sensores especiais que permitem aos robôs ver e entender seu ambiente. Esses sensores permitem que os robôs identifiquem erros e problemas no processo de soldagem. Se algo der errado, o robô pode fazer correções rápidas para resolvê-lo. A adaptabilidade é uma das razões pelas quais a soldagem automatizada é tão eficiente. Em geral, esta tecnologia está repleta de ideias empolgantes que estão revolucionando o mundo da manufatura.

A soldagem robótica automatizada oferece uma das vantagens mais eficazes, que é a segurança das pessoas. Isso reduz significativamente o risco de lesões por movimentos repetitivos, já que os trabalhadores não precisam levantar e robôs de solda à venda

Além disso, eles ou os robôs podem ser programados com instruções específicas de soldagem. Essa programação garante que cada solda seja feita em alto padrão, sempre. No setor de manufatura, o controle de qualidade é extremamente crucial, e a soldagem robótica

Automação na Soldagem em Prototipagem e Produção. A prototipagem é o processo no qual as empresas criam versões muito precoces de produtos para validar seus designs. Nesta fase, eles conseguem realizar soldas precisas e consistentes, assim corte plasma robótico

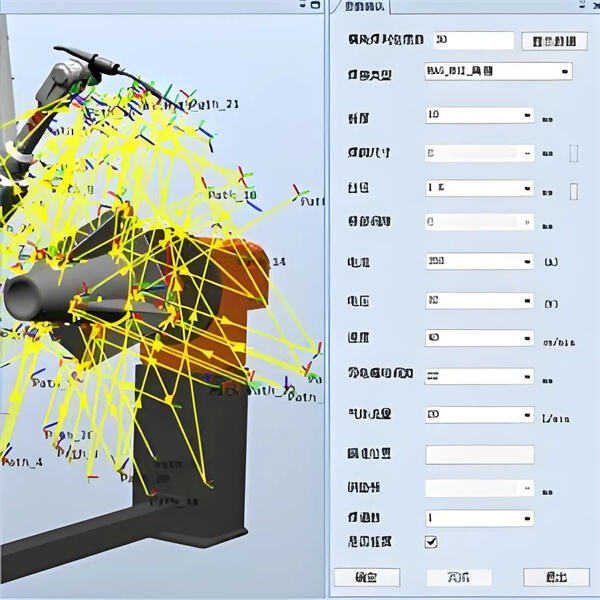

Fornece robô de solda poderoso com carregamento frontal, carregamento lateral, carregamento invertido, montagem em portal, planejamento inteligente de trajetória para múltiplos robôs, múltiplos eixos externos e posicionador para trabalho cooperativo. Realiza simulação de movimento do robô, detecção de colisão, evitação de singularidades e detecção de limite de eixo.

Beijing Minyue Technology Co.,LTD, como a principal empresa de alta tecnologia do mundo no campo de aplicação inteligente não-didática de robôs industriais. Especializamo-nos em fabricação inteligente flexível com nosso sistema autodesenvolvido RobotSmart - Sistema de Tomada de Decisões Inteligentes, SmartVision - Sistema de Visão Binocular de Luz Estruturada e SmartEye - Sistema de Rastreamento de Juntas a Laser. Oferecemos uma nova geração de soluções de soldagem e corte robótico inteligente.

Rápido, preciso, completamente Sem-Programação, alta eficiência e alta precisão. Resolve o complicado processo de ensino dos robôs tradicionais e economiza o tempo de parada durante o processo de ensino.

Adotando as funções de encontrar e rastrear, escaneando a costura de solda, confirmando a posição e as informações da costura de solda, corrigindo a posição da costura de solda entre o desenho 3D digital e a peça real, resolvendo o problema de solda desalinhada devido aos erros dos materiais de entrada e deformação térmica.